Novel nano magnetic particle suspension system and preparation method thereof

A technology of nano-magnetic particles and a preparation method, which is applied in the biological field, can solve the problems of slow sedimentation rate and poor dispersion stability of nano-magnetic particles, and achieve the effect of good paramagnetism and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

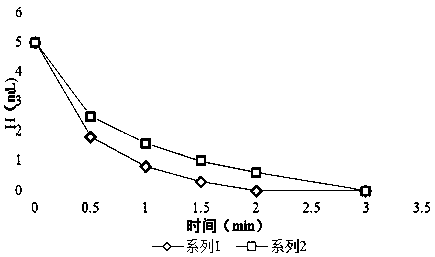

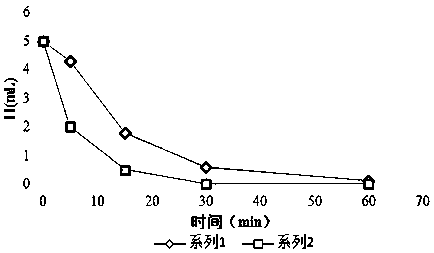

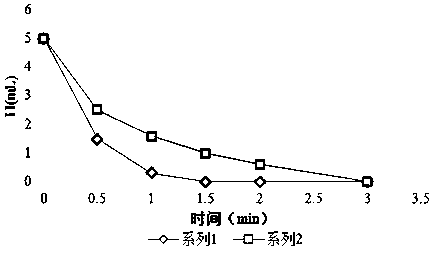

Image

Examples

Embodiment 1

[0022] 1. The amount of raw materials and preparation steps of the new nano-magnetic particle suspension system

[0023] (1) Add 800mL of purified water into the container, weigh 0.1g of disodium hydrogen phosphate dodecahydrate and 0.1g of sodium dihydrogen phosphate dihydrate in the above-mentioned purified water, stir it with a magnetic stirrer for at least 15 minutes to completely dissolve it, and obtain Phosphate buffer solution, the pH range is 7.00±0.01;

[0024] (2) Weigh 5.0g of sodium chloride, 0.01g of 4-aminoantipyridine, and 1.0g of bovine serum albumin into the above buffer, and stir with a magnetic stirrer for at least 30 minutes to mix the solution evenly;

[0025] (3) Measure 10mL isopropanol, 0.01mL Triton X-100, 0.1mL Proclin-300 into the above solution, stir with a magnetic stirrer for at least 15 minutes to mix the solution evenly;

[0026] (4) Dilute the solution to 1 L with purified water, and filter it with a 0.22 μm filter to sterilize;

[0027] (5) ...

Embodiment 2

[0033] 1. The amount of raw materials and preparation steps of the magnetic particle suspension system

[0034] (1) Add 800mL of purified water into the container, weigh 1.0g of disodium hydrogen phosphate dodecahydrate and 0.5g of sodium dihydrogen phosphate dihydrate in the above-mentioned purified water, stir it with a magnetic stirrer for at least 15 minutes to completely dissolve it, and obtain Phosphate buffer solution, the pH range is 7.00±0.01;

[0035] (2) Weigh 20g of sodium chloride, 0.1g of 4-aminoantipyridine, and 20g of bovine serum albumin into the above buffer, and stir with a magnetic stirrer for at least 30 minutes to mix the solution evenly;

[0036] (3) Measure 20mL isopropanol, 0.1mL Triton X-100, 1.0mL Proclin-300 in the above solution, stir with a magnetic stirrer for at least 15 minutes to mix the solution evenly;

[0037] (4) Dilute the solution to 1 L with purified water, and filter it with a 0.22 μm filter to sterilize;

[0038] (5) Measure an appr...

Embodiment 3

[0044] 1. The amount of raw materials and preparation steps of the magnetic particle suspension system

[0045] (1) Add 800mL of purified water into the container, weigh 2.0g of disodium hydrogen phosphate dodecahydrate and 0.75g of sodium dihydrogen phosphate dihydrate in the above purified water, stir it with a magnetic stirrer for at least 15 minutes to completely dissolve it, and obtain Phosphate buffer solution, the pH range is 7.00±0.01;

[0046] (2) Weigh 30g of sodium chloride, 0.5g of 4-aminoantipyridine, and 30g of bovine serum albumin into the above buffer, and stir with a magnetic stirrer for at least 30 minutes to mix the solution evenly;

[0047] (3) Measure 40mL of isopropanol, 0.25mL of Triton X-100, and 2.5mL of Proclin-300 into the above solution, and stir with a magnetic stirrer for at least 15 minutes to mix the solution evenly;

[0048] (4) Dilute the solution to 1 L with purified water, and filter it with a 0.22 μm filter to sterilize;

[0049] (5) Meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com