Patents

Literature

41 results about "Sodium dihydrogen phosphate dihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

InactiveCN103933611AHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

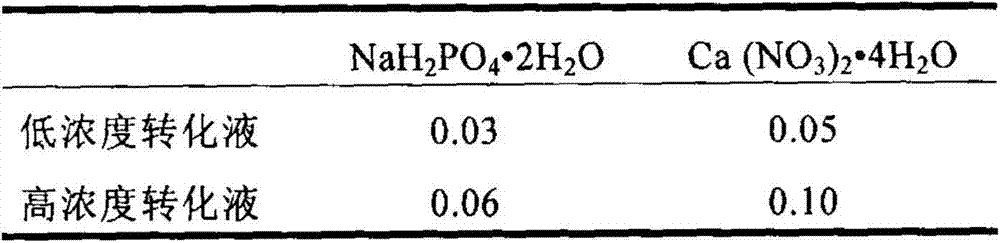

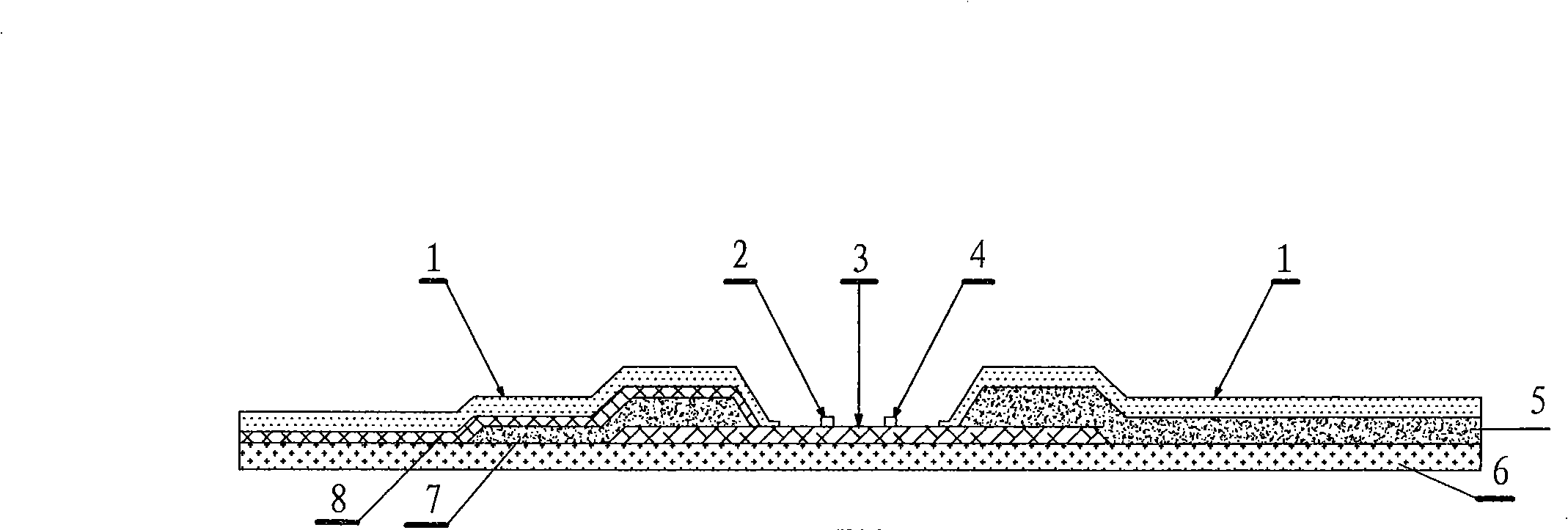

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

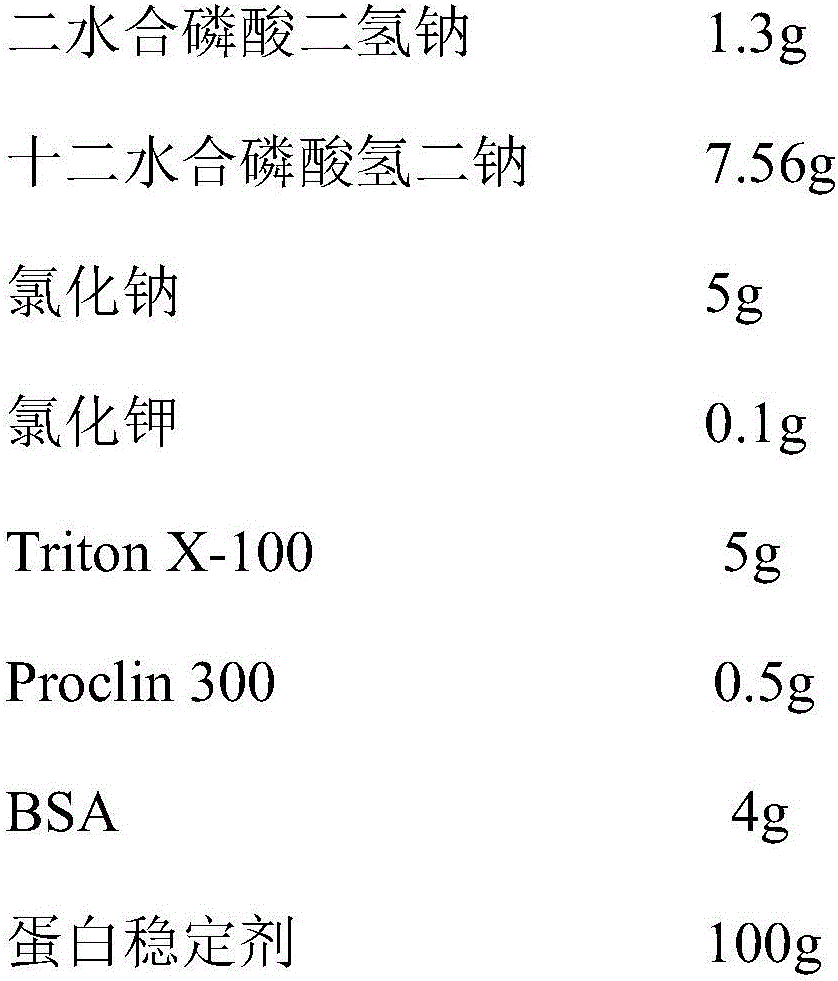

Cleaning solution for chemiluminescence immunity analyzer

InactiveCN105754733ASimple configurationLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium dihydrogen phosphate dihydratePreservative

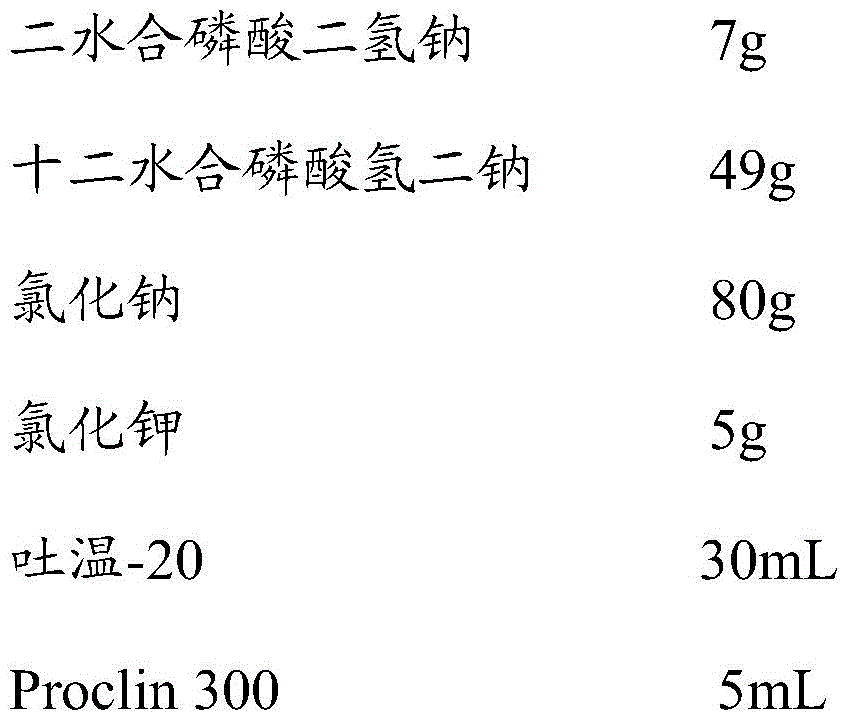

The invention discloses a cleaning solution for a chemiluminescence immunity analyzer. The cleaning solution is prepared from sodium dihydrogen phosphate dihydrate, disodium hydrogen phosphate dodecahydrate, sodium chloride, potassium chloride, a surfactant, a preservative and deionized water; in the cleaning solution, the concentration of the sodium dihydrogen phosphate dihydrate is 0.70 to 2.8g / L, the concentration of the disodium hydrogen phosphate dodecahydrate is 0.80 to 4.9g / L, the concentration of the sodium chloride is 7.5 to 9.5g / L, the concentration of the potassium chloride is 0.05 to 1g / L, the concentration of the surfactant is 1 to 7ml / L and the concentration of the preservative is 0.1 to 0.5ml / L; the pH value of the cleaning solution is 6.3 to 7.6. The cleaning solution disclosed by the invention is simple to prepare, low in cost, high in accuracy and precision and good in repeatability.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

Composition with efficacies of whitening, moisturizing, repairing and caring skin, as well as preparation method and applications of composition

InactiveCN107411982AIncrease brightnessFirming and Lifting ContourCosmetic preparationsToilet preparationsArginineCuticle

The invention relates to a composition with the efficacies of whitening, moisturizing, repairing and caring the skin, as well as a preparation method and applications of the composition. The skin care composition is prepared from the following raw materials: water, sodium hyaluronate, sodium dihydrogen phosphate dihydrate, potassium chloride, sodium hydroxide, calcium chloride, glutamine, benzalkonium chloride, magnesium sulfate, aminobutyric acid, sodium ascorbate, alanine, arginine, lysine hydrochloride, valine, histidine, leucine, taurine, coenzyme A, alcohol, polysorbate 80, thiamine, disodium diphosphate, recombinant human epidermal cell growth factors and the like. The skin care composition disclosed by the invention can permeate the muscle bottom for replenishing water for the skin from the deep layer, so that the skin is full of elasticity, the color of the skin is brightened, the fine wrinkles are reduced, the skin is clean and watery, the balance of water and oil is regulated, the pores are shrunk, meanwhile, the brightness of the face can be increased, the injured epidermal layer is effectively repaired, the activity of tyrosinase is inhibited, the generation of skin melanin is reduced, so that the skin is healthy, natural and white.

Owner:刘毅

Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy

InactiveCN104888271AGood biocompatibilitySimple processMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium phosphate coating

The invention relates to a method for preparing a strontium-containing hydroxyapatite coating on the surface of a biodegradable magnesium alloy. The method comprises the following steps: polishing a magnesium alloy matrix to remove a surface oxidation layer, and cleaning; preparing a hydrothermal solution from calcium nitrate tetrahydrate, EDTA-2 Na, sodium dihydrogen phosphate dihydrate and strontium nitrate; and placing the well treated magnesium alloy matrix into the hydrothermal solution for hydrothermal reaction to obtain the strontium-containing hydroxyapatite coating, a biomimetic calcium phosphate coating, wrapping the magnesium alloy matrix. Compared with the prior art, as the hydrothermal method is adopted to prepare hydroxyapatite, not only is the degradation rate of the magnesium alloy in a human body effectively slowed down, but also the biocompatibility of the magnesium alloy is further improved. As strontium element is added into the hydroxyapatite coating, and as one of trace elements of the human body, strontium has the functions of promoting bone formation and inhibiting bone breakage, both the biological activity and the biocompatibility are improved.

Owner:TONGJI UNIV

Preparation method of biodegradable magnesium alloy surface-modified hydroxyapatite coating

InactiveCN103446627AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

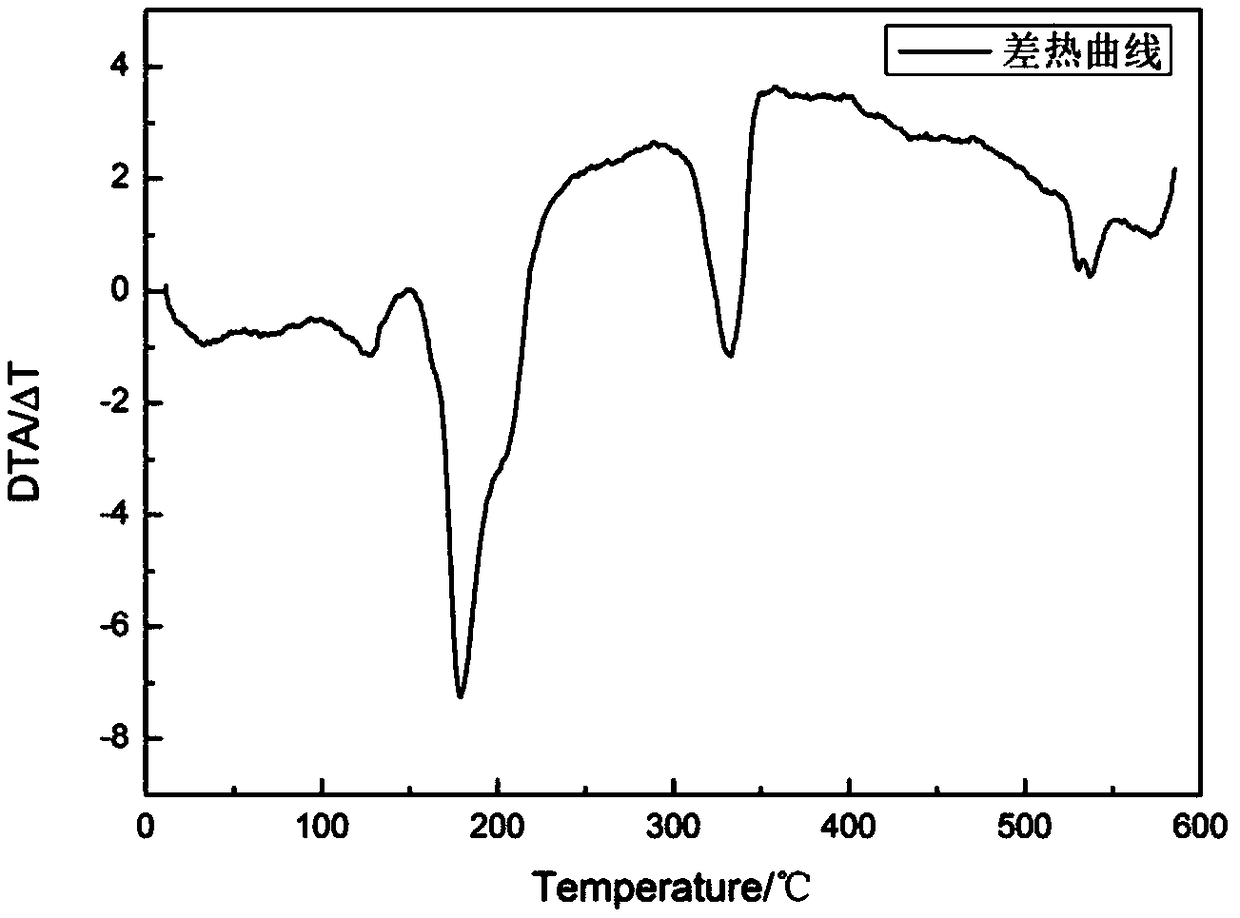

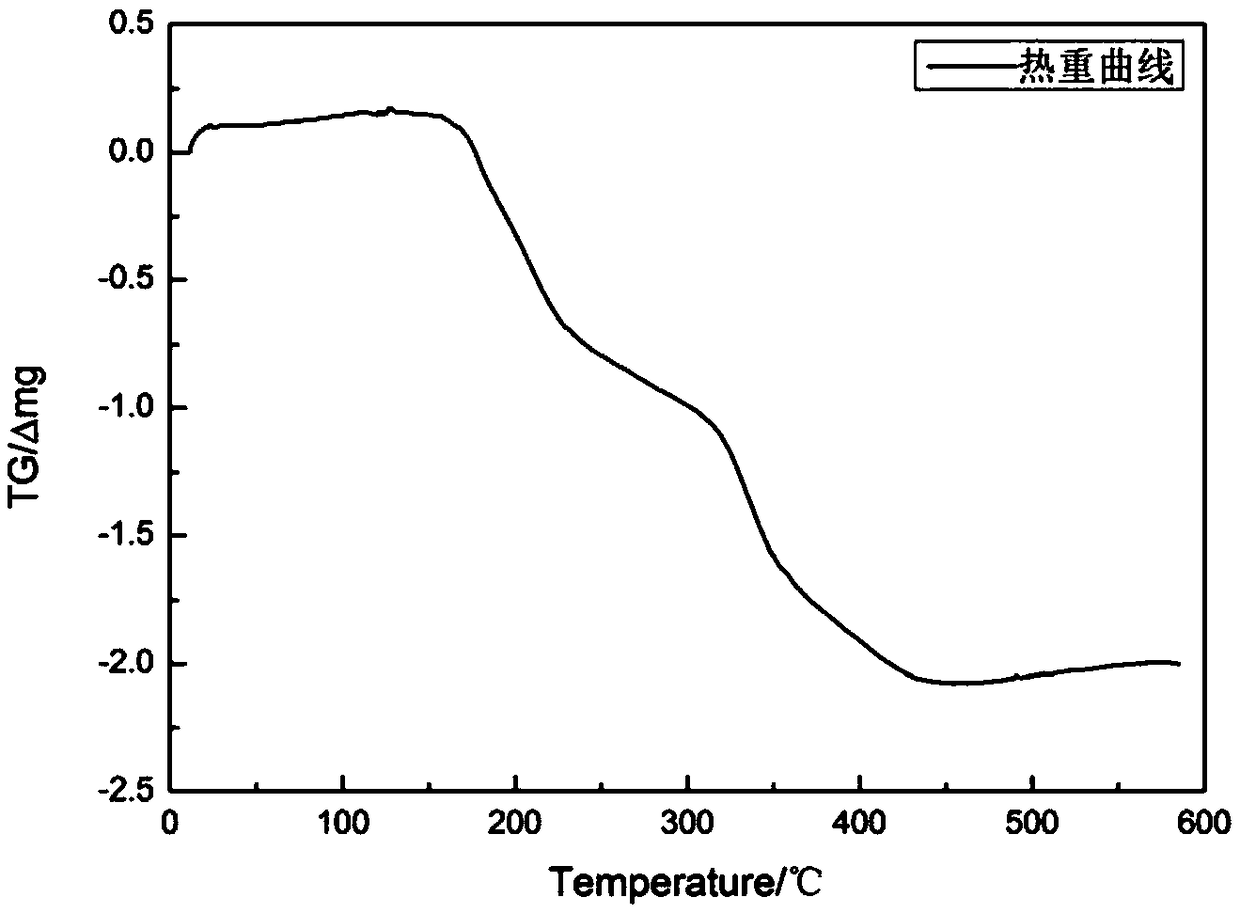

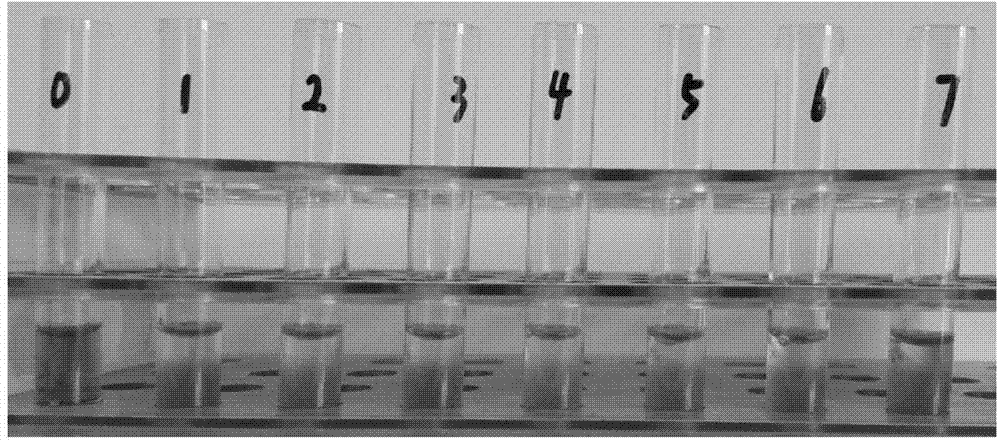

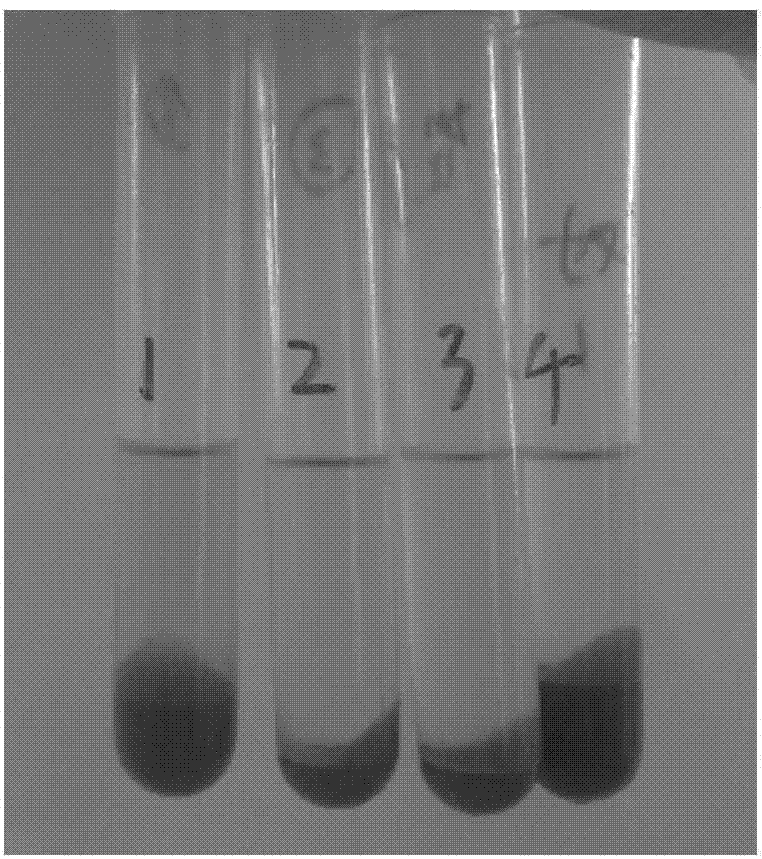

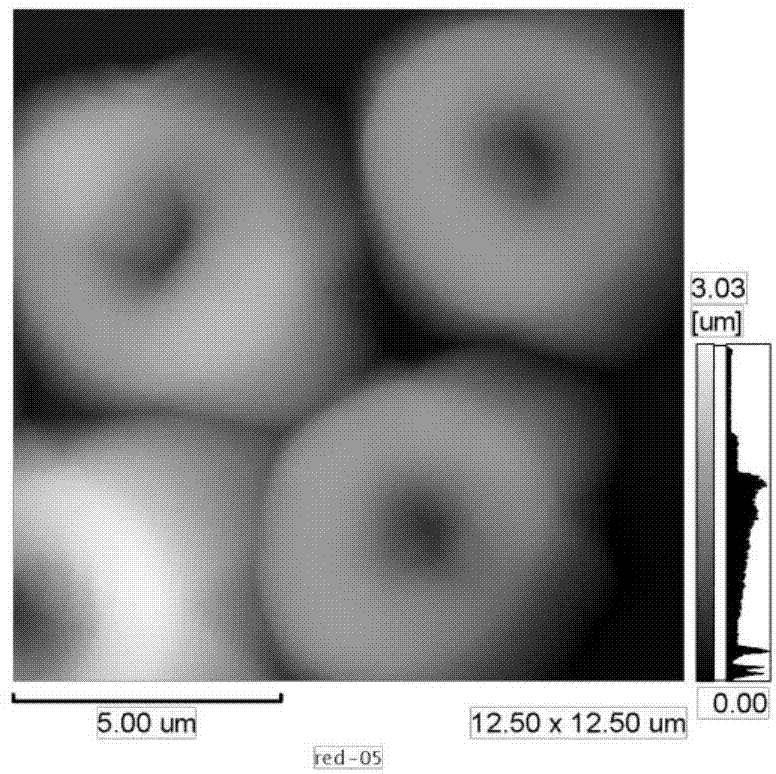

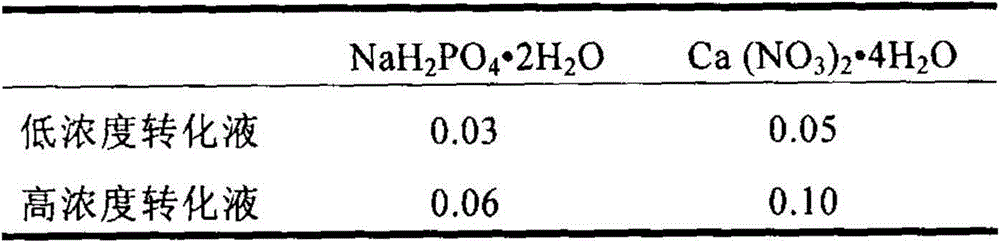

The invention relates to a preparation method of a biodegradable magnesium alloy surface-modified hydroxyapatite coating. The method specifically comprises the following steps: cutting the magnesium alloy into samples; polishing the samples by aluminum oxide water-resistant abrasive paper to remove surface oxide layers of the magnesium alloy; sequentially ultrasonic-cleaning with deionized water and absolute ethyl alcohol for 5-30 minutes, and drying at room temperature; preparing a conversion liquid by adopting sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate; controlling the molar ratio of calcium and phosphorus at (1:1)-(2:1), the concentration of Ca<2+> at 0.01-0.2M and the P<5+> concentration at 0.01-0.2M; placing pre-treated matrix sample in the conversion liquid to be soaked for 5-100 hours to obtain a calcium and phosphorus coating; preparing the hydroxyapatite coating through the calcium and phosphorus coating by adopting a thermal treatment process: soaking the samples in calcium and phosphorus liquor for 24-72 hours; taking out and directly placing in a Muffle furnace; carrying out thermal treatment at 250-350 DEG C for 2-5 hours; detecting performance. According to the method provided by the invention, the samples taken out from the calcium and phosphorus liquor are placed in the Muffle furnace for direct thermal treatment, so that the method is simpler and easier to operate and control, and the samples can be converted into the hydroxyapatite coating to achieve a considerable corrosion resistant effect.

Owner:TONGJI UNIV

Colloidal gold method detecting reagent for extrauterine pregnancy and number of pregnancy days, and preparation thereof

InactiveCN101294966AResolve detectionSolve time-consuming and costly problemsBiological testingCelluloseObstetrics

The invention discloses an ectopic pregnancy and pregnant days colloid gold detection agent and manufacturing method thereof used for the problem of fast detection for pregnancy, comprising a piece of detecting test paper and urine sample treatment solution; wherein, the detecting test paper consists of a base plate, a cellulose nitrate membrane, a gold label anti-Beta HCG monoclone antibody layer, an Alpha-HCG monoclone antibody line, a sheep anti-rat polyclonal antibody line, an absorbing pad and a sample pad; the matching composition of the urine sample treatment solution is that: 12.5 to 18.0 portions of disodium hydrogen phosphate dodecahydrate, 1.2 to 1.7 portions of sodium dihydrogen phosphate dihydrate, 40.0 to 48.0 portions of sodium chloride and 4600 to 5300 portions of distilled water; the ectopic pregnancy and pregnant days colloid gold detection agent and manufacturing method of the invention are characterized by fast and simple detection, the operation of blood-drawing detection for 2 to 6 hours can be replaced by 2 to 3 minutes with time-saving, manual-saving and cost-saving; besides, the ectopic pregnancy and pregnant days colloid gold detection agent and manufacturing method thereof have the advantages of detecting ectopic pregnancy and pregnant days in a semiquantitative way, etc., and can be used for external detection of the pregnant condition and artificial abortion and assisted diagnosis.

Owner:崔学礼

Preparation method for high-efficiency and environment-friendly fire extinguishing agent

InactiveCN108619651AImprove fire extinguishing efficiencyHigh temperature resistantFire extinguisherElectricitySodium dihydrogen phosphate dihydrate

A preparation method for a high-efficiency and environment-friendly fire extinguishing agent comprises the following steps that, by weight, 4-6 parts of sodium dihydrogen phosphate dihydrate, 1.5-3 parts of ammonium bicarbonate and 2-3 parts of sodium carbonate are taken and mixed to be added into an agate mortar, after 1-2 hours of grinding, sieving is carried out, and particle sizes are controlled within 200-300 meshes; then, by weight, 0.5-1.5 parts of white carbon black is added, and after sufficient mixing, grinding continues to be carried out for 1-2 hours; then, sieving is carried out,the particle sizes are controlled within 300-400 meshes, simethicone is added, the adding amount of the simethicone per one weight part of a second mixture is 0.05-0.1ml, a mixture is stirred to be uniform and added into an electric constant-temperature digital readout blast air oven, the temperature is set to be 100 DEG C-105 DEG C, and after 2-3 hours of temperature keeping, the mixture is takenout. The fire extinguishing agent prepared through the method is high in efficiency and environmentally friendly.

Owner:ANHUI SCI & TECH UNIV

Bi2O2CO3-BiPO4 composite photocatalyst and preparation method thereof

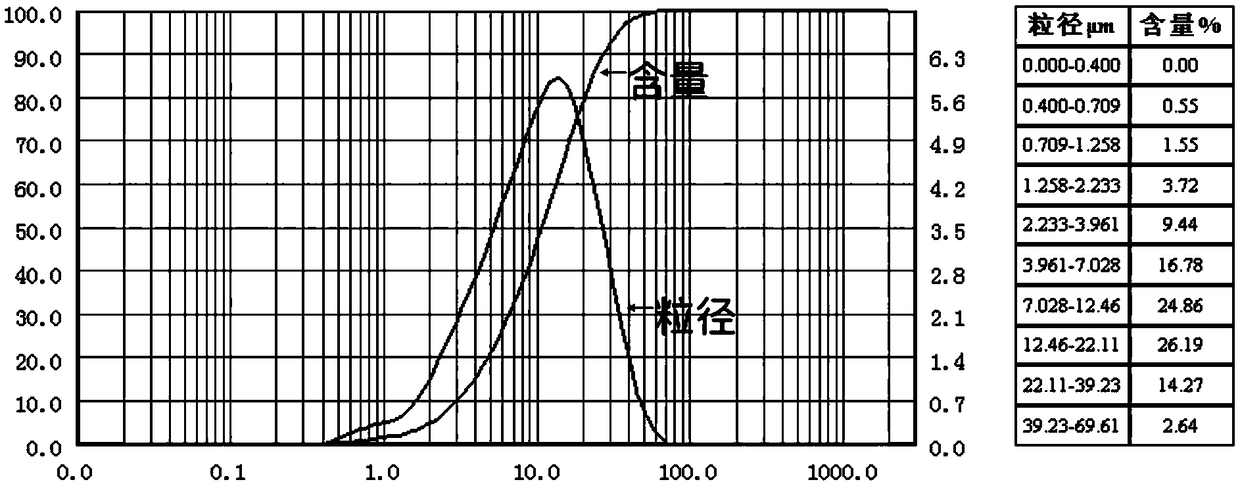

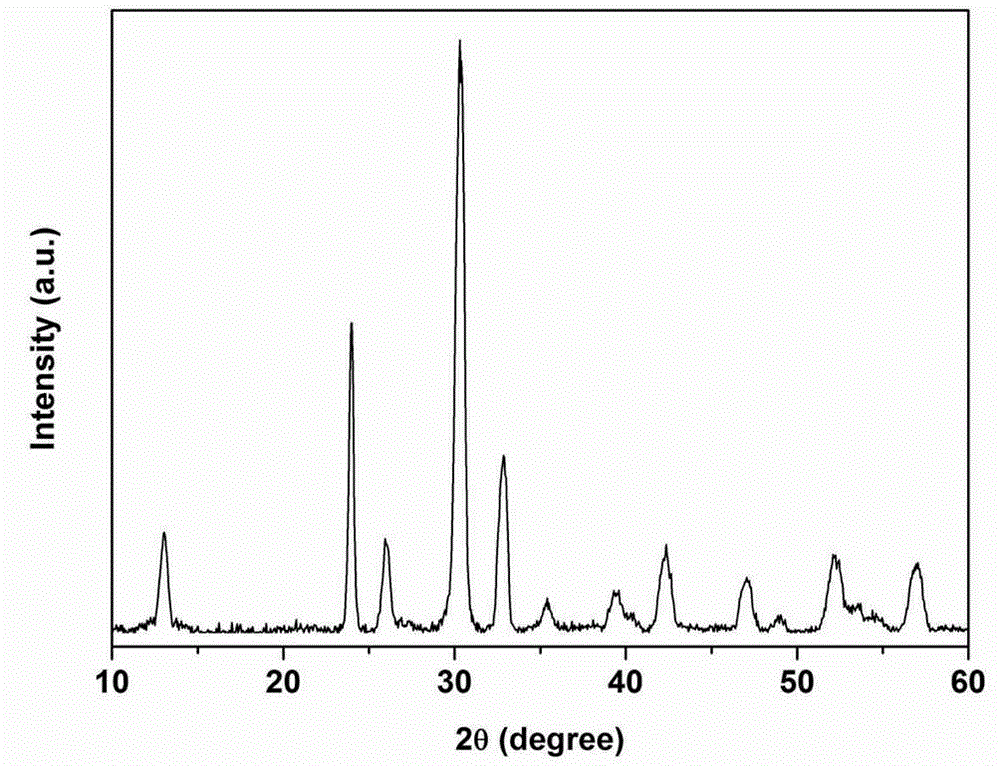

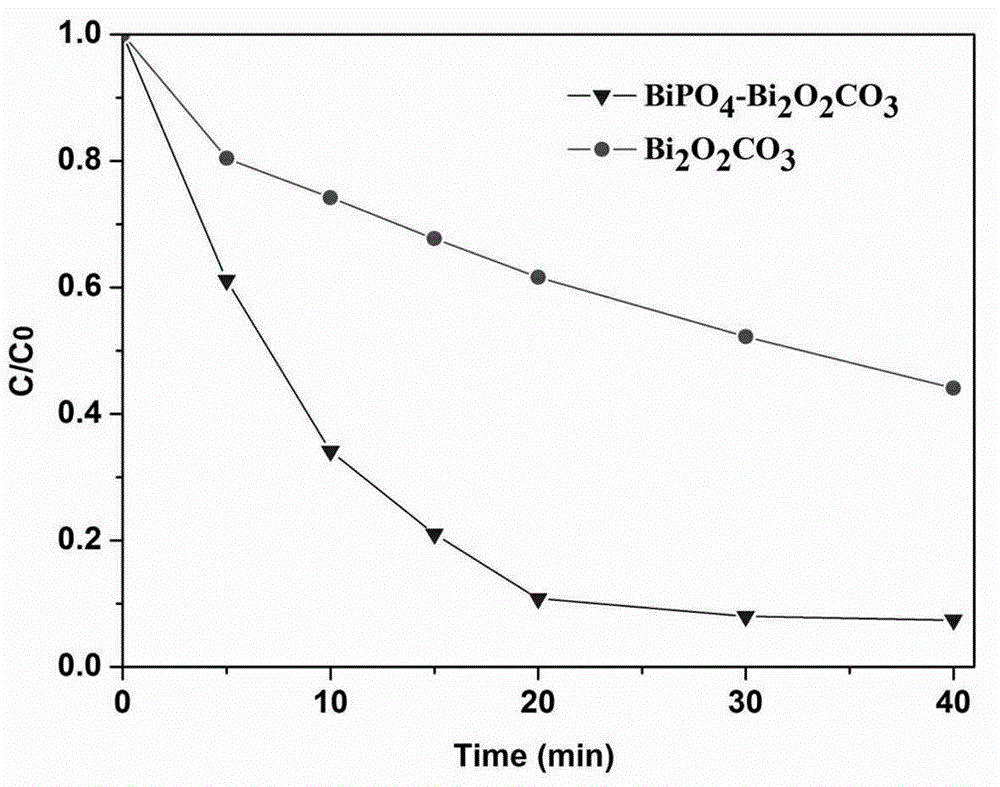

InactiveCN104971753AEasy to migrateImprove separation efficiencyPhysical/chemical process catalystsSodium dihydrogen phosphate dihydrateCentrifugation

The invention discloses a Bi2O2CO3-BiPO4 composite photocatalyst and a preparation method thereof. The invention relates to the technical field of inorganic environment-friendly photocatalytic materials. A technical scheme of the invention comprises the following steps: (1) sodium dihydrogen phosphate dihydrate, bismuth nitrate pentahydrate, urea and deionized water are well mixed under stirring; the pH value of the mixed solution is regulated to 4 with ammonia water; the mixed solution is stirring for 2h under room temperature; (2) the mixed solution is transferred to a hydrothermal reactor; the hydrothermal reactor is placed in a microwave digestion instrument; and a microwave reaction is carried out for 10-30min under a temperature of 180-200 DEG C; (3) when the reaction is finished, cooling, centrifugation, washing and drying are carried out, such that the Bi2O2CO3-BiPO4 composite photocatalyst with high catalytic activity is obtained. With the composite Bi2O2CO3-BiPO4 photocatalyst provided by the invention, photo-generated charge separation efficiency can be effectively improved, and the photocatalytic performance can be improved.

Owner:HENAN NORMAL UNIV

Method for preparing degradable biomedical magnesium alloy/calcium-phosphorus coating composite material

InactiveCN103451640AImprove corrosion resistanceConvenient researchMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium-phosphorus product

The invention relates to a method for preparing a degradable biomedical magnesium alloy / calcium-phosphorus coating composite material. The method comprises the specific steps: cutting magnesium alloy into samples in moderate sizes, polishing by sequentially using 800# alumina waterproof sandpaper and 2,000# alumina waterproof sandpaper so as to remove an oxide layer from the surface of magnesium alloy, carrying out ultrasonic cleaning for 5-30 minutes by sequentially using deionized water and anhydrous ethanol, and drying at room temperature for later use; preparing a conversion solution from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, controlling the mole ratio of calcium to phosphorus to be (1:1) to (2: 1), controlling the concentration of Ca<2+> to be 0.01-0.2M, and controlling the concentration of P<5+> to be 0.01-0.2M; putting base body samples obtained through pretreatment into the conversion solution, and soaking for 5-100 hours, thereby obtaining calcium-phosphorus coating layers; carrying out performance detection. According to the method, magnesium-alloy base bodies are subjected to ultrasonic pretreatment firstly, so that the bonding performance between the calcium-phosphorus coating layers and the surfaces of the base bodies is better; the calcium / phosphorus mole ratio of the conversion solution used by the method is 1-2, and the concentration of both calcium and phosphorus is higher than that of an ordinary bionic solution, so that the efficiency of chemical conversion can be increased obviously, and a calcium-phosphorus product is closer to human bone ingredients.

Owner:TONGJI UNIV

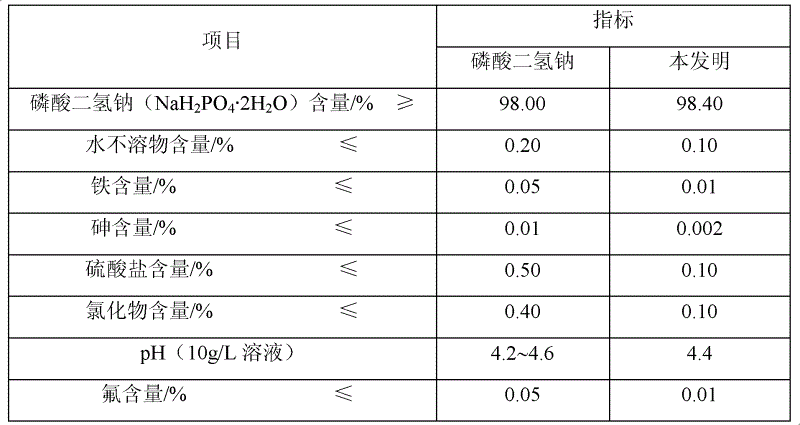

Process for preparing alpha-acetyl-gamma-butyrolactone for co-production of various phosphates

InactiveCN102617520ARealize joint productionSimple conditionsOrganic chemistryPhosphorus compoundsEcological environmentFiltration

The invention provides a process for preparing alpha-acetyl-gamma-butyrolactone for co-production of various phosphates. The process is applicable to producing the alpha-acetyl-gamma-butyrolactone through acylation and phosphoric acid neutralization of gamma-butyrolactone and acetyl reagents serving as raw materials under the catalytic action of metallic sodium, and effective separation of an organic phase and an aqueous phase is achieved through controlling the concentration of phosphoric acid and the system temperature during oil-water separation. The organic phase is rectified to obtain alpha-acetyl-gamma-butyrolactone; and sodium dihydrogen phosphate dihydrate, sodium hexametaphosphate, sodium trimetaphosphate, sodium acid pyrophosphate, sodium dihydrogen phosphate dodecahydrate, trisodium phosphate dodecahydrate, sodium tripolyphosphate and sodium pyrophosphate are obtained through steps such as pH adjustment, concentration, decompressional filtration and the like of the aqueous phase. The process produces both main products and byproducts, achieves co-production of various products by one process, energy conservation, emission reduction and ecological environment protection, and is safe in operation, simple in process, easy to industrialize and low in cost.

Owner:SHANXI UNIV +1

Novel nano magnetic particle suspension system and preparation method thereof

InactiveCN109142715AImprove dispersion stabilityRapid solid-liquid separationBiological testingSodium phosphatesParamagnetism

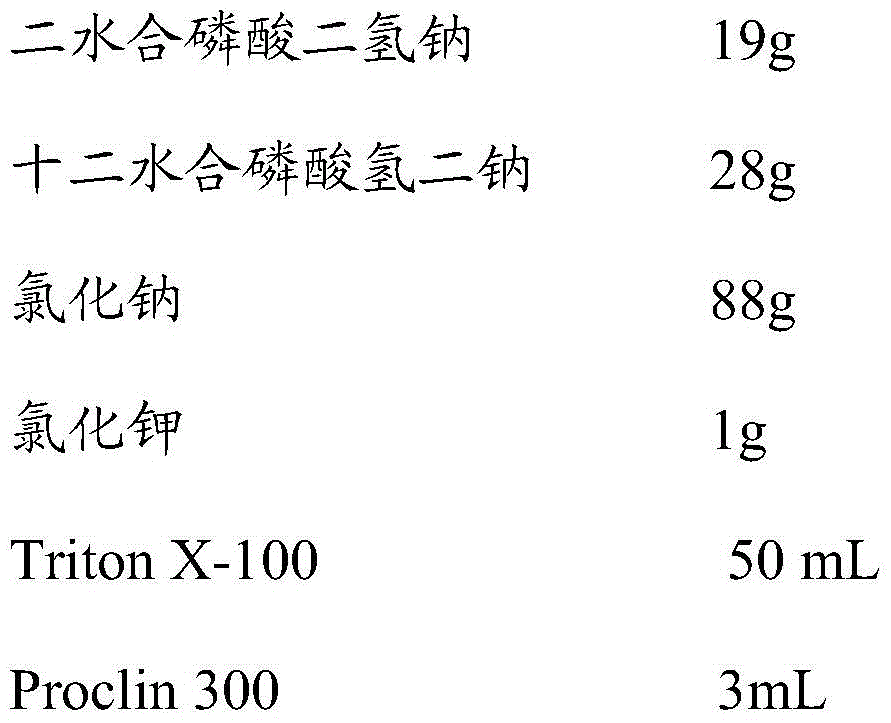

The invention provides a novel nano magnetic particle suspension system and a preparation method thereof. According to the suspension system, with purified water as a solvent, every 1L of the suspension system contains 0.1-5 g of sodium phosphate dibasic dodecahydrate, 0.1-1 g of sodium dihydrogen phosphate dihydrate, 5-50 g of sodium chloride, 0.01-1.0 g of 4-aminoantipyrine, 1-50 g of bovine serum albumin, 10-50 mL of isopropanol, 0.01-0.5 mL of Triton X-100 and 0.1-5 mL of Proclin-300. The mass concentration of magnetic particles in the suspension system is 5.0%. The novel nano magnetic particle suspension system has good dispersion performance, the magnetic particles are evenly distributed, and the good dispersion and stabilization performance can be guaranteed; under the effect of themagnetic field, the nano magnetic particles can quickly settle, solid and liquid separation is quickly achieved, and the system has good paramagnetism.

Owner:JIANGNAN UNIV +1

Molded coal auxiliary agent compound

The invention discloses a molded coal auxiliary agent compound comprising the following raw material components by mass: 10-15 parts of sodium carboxymethyl cellulose, 5-8 parts of polyving akohol, 3-5 parts of sodium tripolyphosphate, 5-10 parts of sodium dihydrogen phosphate dihydrate, 1-3 parts of calcium hydroxide, 2-4 parts of nano calcium carbonate, 3-6 parts of ferric chloride, 3-8 parts of copper chloride, 2-5 parts of ammonium hydrogen carbonate, 10-15 parts of limestone, 3-5 parts of potassium chlorate, 2-5 parts of potassium sulfate, 1-3 parts of sodium permanganate, 2-3 parts of ammonium nitrate, 4-6 parts of sodium chlorite, 5-8 parts of ammonium chloride, 20-30 parts of mullite powder, 20-25 parts of titanium dioxide, 30-40 parts of sunflower oil residue, 1-5 parts of polyvinyl butyral resin, 3-8 parts of polyvinyl alcohol fiber, 3-5 parts of polyvinylpyrrolidone and 10-20 parts of water. The molded coal auxiliary agent compound has the advantages of low cost, and molded coal prepared by mixing wash coal mud and wash middling coal needs no drying.

Owner:李永亮

ATP content determination kit and method thereof

InactiveCN105699507AEasy extractionReduce testing costsComponent separationAtp contentRetention time

The invention discloses an ATP content determination kit and a method thereof. The kit comprises a reagent I prepared by dissolving concentrated perchloric acid in distilled water, a reagent II prepared by dissolving sodium hydroxide in distilled water, a reagent III prepared from sodium phosphate dibasic dodecahydrate, a reagent IV prepared from sodium dihydrogen phosphate dihydrate and a reagent V prepared from ATP. The method improves the extraction process of ATP and is capable of removing influence of impurities in a sample by firstly adding an acidic extraction solution into the sample for fully extracting and then adding an alkaline extraction solution for neutralizing. The minimum detection limit of the method reaches up to 0.1Mu mol / mL; compared with a conventional spectrophotometric method, the minimum detection limit is significantly improved. The reagent components of the kit only comprise absolute methanol, disodium hydrogen phosphate and sodium dihydrogen phosphate; the detection cost is greatly reduced. The method is qualitative and quantitative in through-peak area and retention time; the detection accuracy is significantly improved.

Owner:SUZHOU COMIN BIOTECH

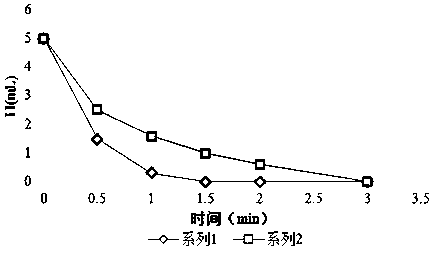

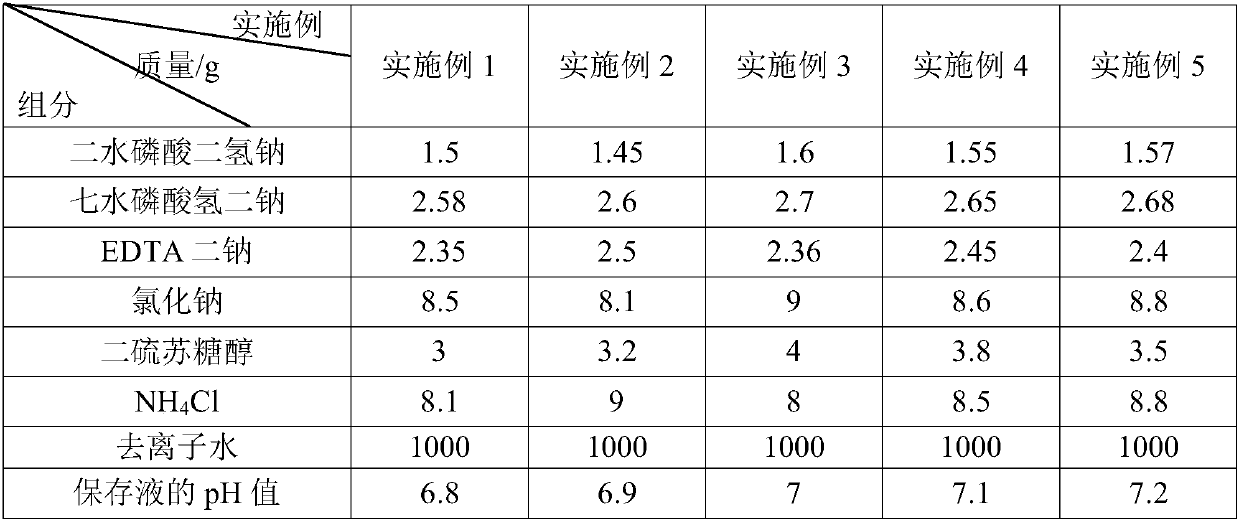

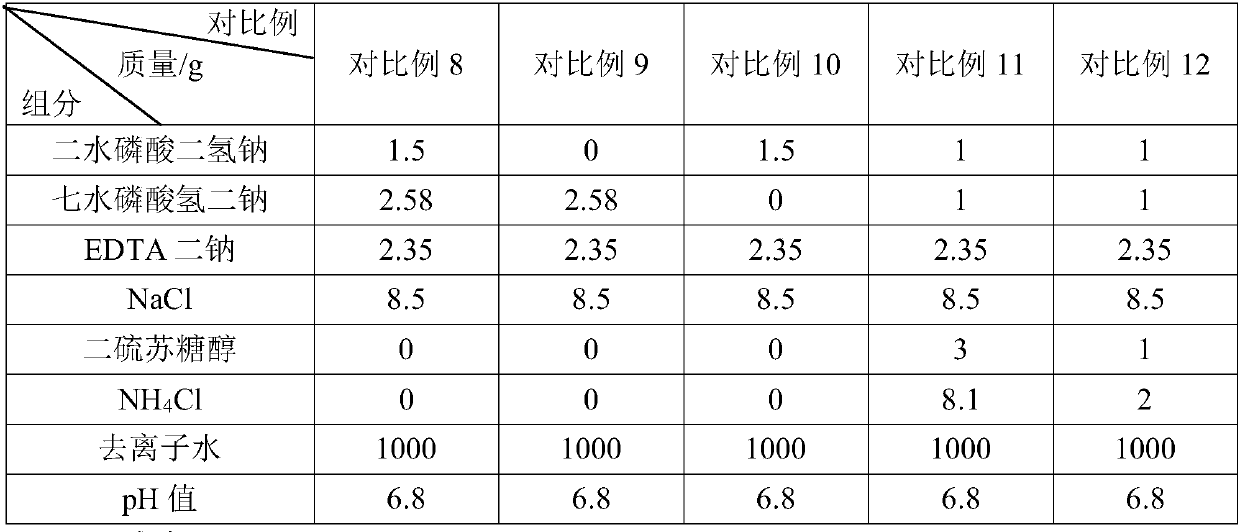

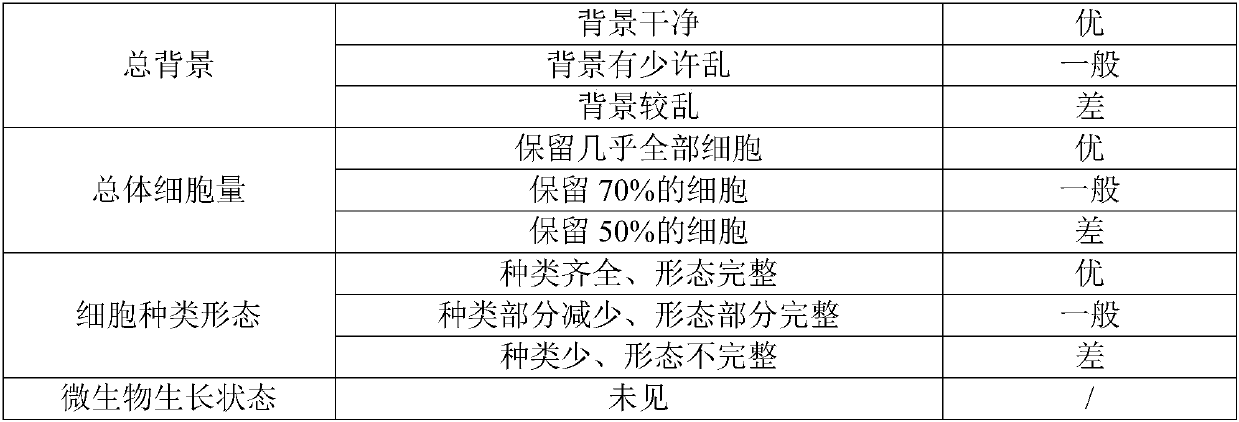

Preservation solution and preparation process and application method thereof

InactiveCN109682971AGood removal effectRelease fullyDead animal preservationMaterial analysisSodium dihydrogen phosphate dihydrateDisodium hydrogen phosphate heptahydrate

The invention discloses a preservation solution and a preparation process and application method thereof. The preservation solution is prepared from, by weight, 1.45-1.6 parts of sodium dihydrogen phosphate dihydrate, 2.58-2.7 parts of disodium hydrogen phosphate heptahydrate, 2.36-2.5 parts of EDTA disodium, 8.1-9 parts of sodium chloride, 3-4 parts of dithiothreotol, 8.1-9 parts of NH4Cl, 1,000mL of deionized water and a pH regulator, and the pH value of the preservation solution is 6.8-7.2. According to the preservation solution, cell mucus and fresh blood carried in cell samples in the sampling process can be effectively moved, and then effective cells are fully released; in the preservation process, the cell mucus and fresh blood are not likely to affect the effective cells, and thefinally obtained detection results can achieve the accurate effect.

Owner:HANGZHOU HEALTHSKY BIOTECH CO LTD

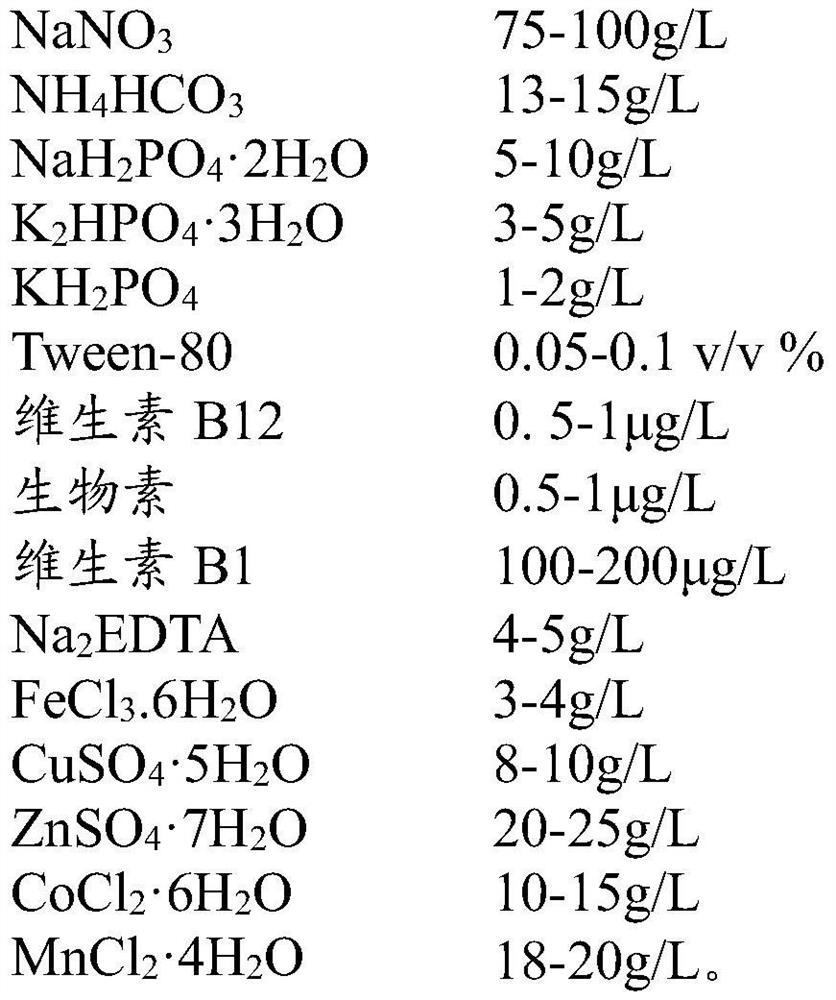

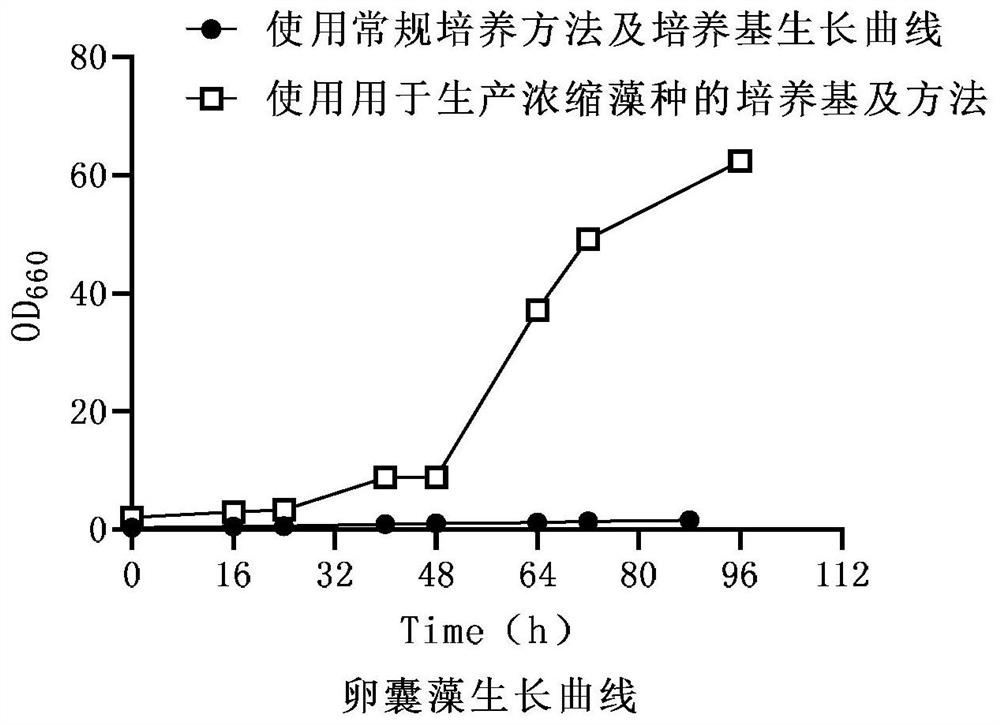

Microalgae culture medium and culture method

PendingCN113462578APromotes mitosisFast growthUnicellular algaeMicroorganism based processesBiotechnologySodium dihydrogen phosphate dihydrate

The invention relates to the technical field of microalgae culture, in particular to a microalgae culture medium and a culture method. The culture medium comprises sodium nitrate, ammonium bicarbonate, sodium dihydrogen phosphate dihydrate, monopotassium phosphate trihydrate, monopotassium phosphate, Tween 80, NaCl, trace elements and vitamins. The culture medium provides appropriate nutritional ingredients for the growth of microalgae, can effectively promote the mitosis of algae cells and accelerate the growth speed of algae, and is suitable for large-scale factory culture.

Owner:HAINAN GREEN ALGAE WORLD BIOTECHNOLOGY CO LTD

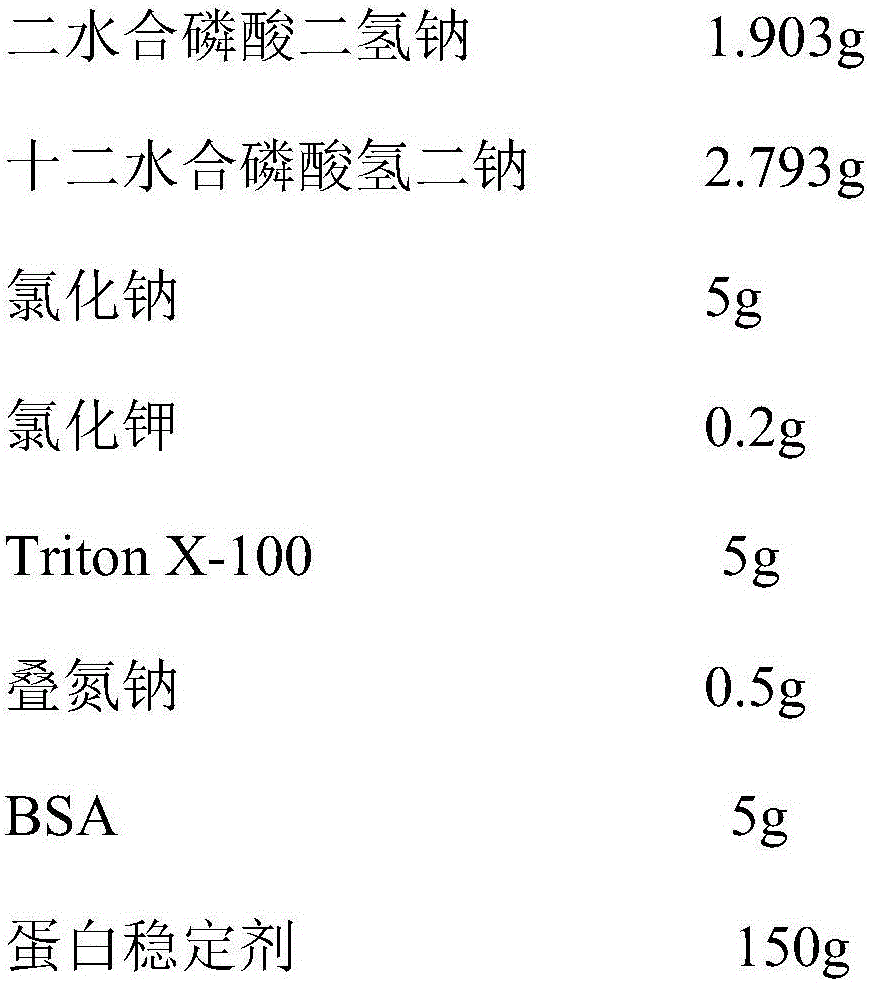

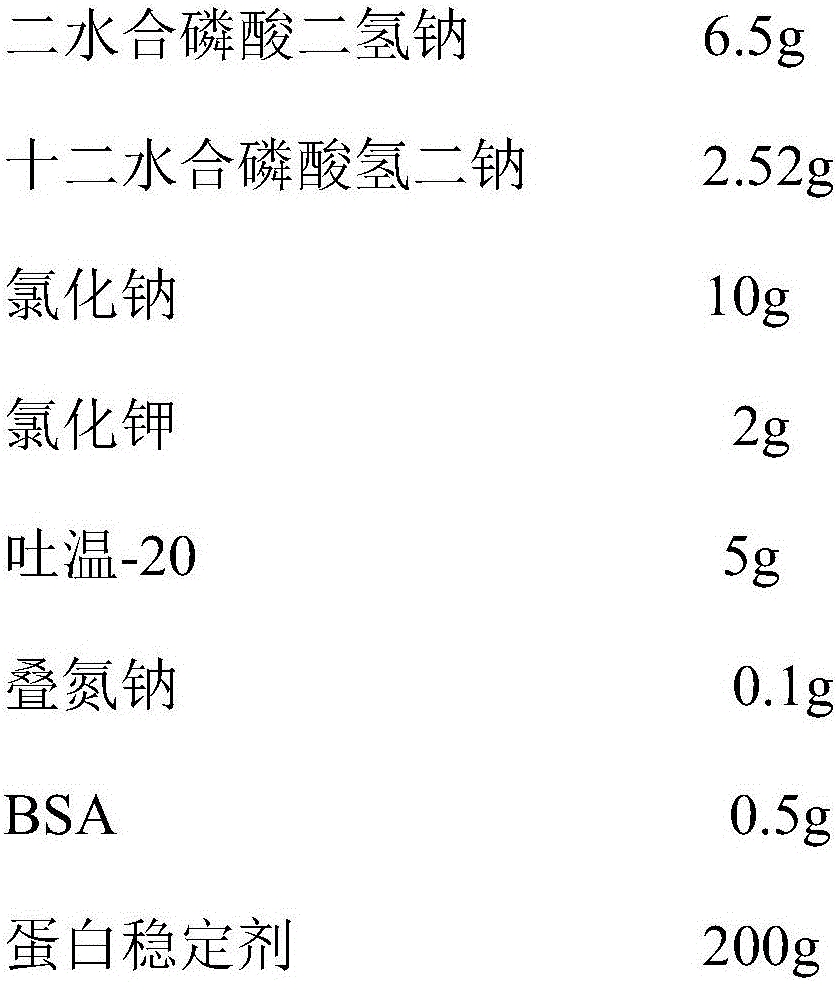

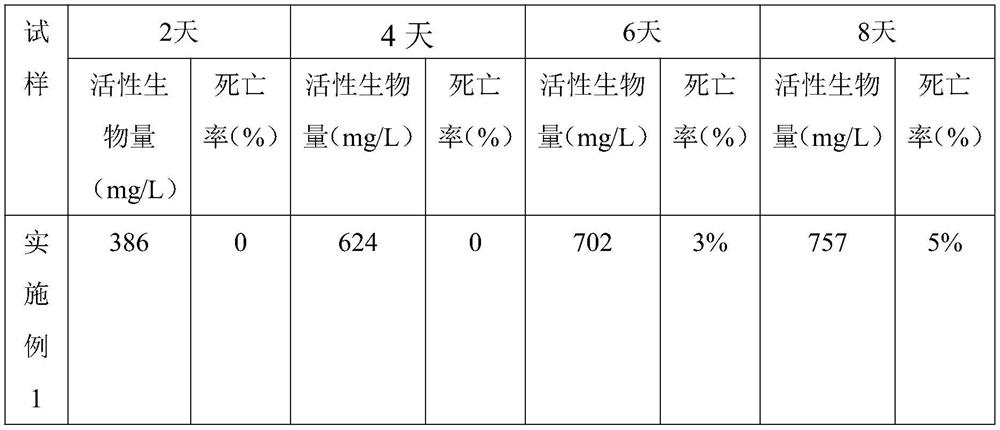

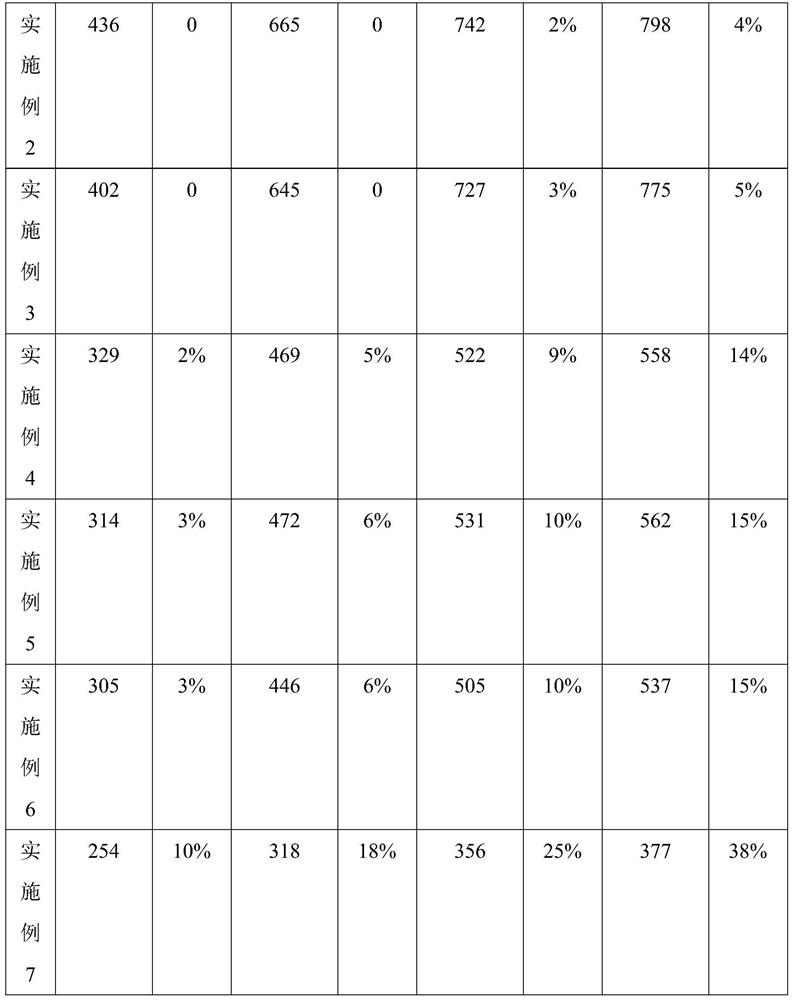

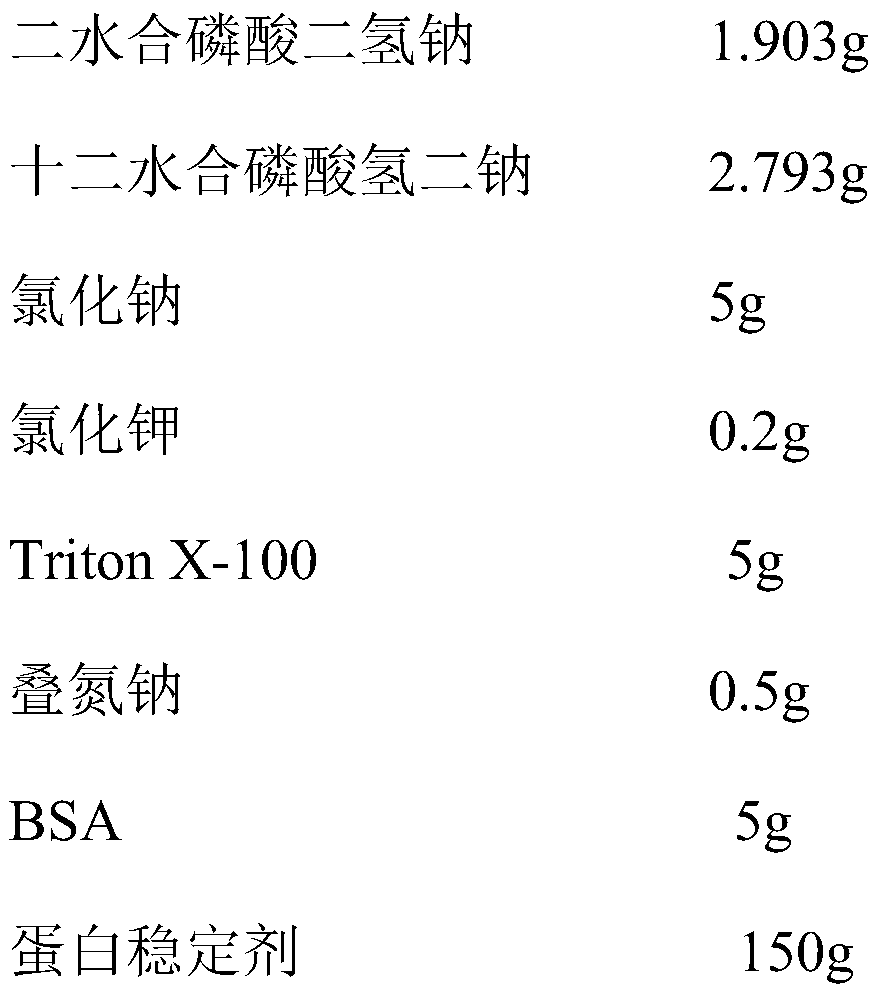

Liquid-state NAG (glucosaminidase) correction solution and preparation method thereof

ActiveCN106755281AEasy to prepareEasy to useMicrobiological testing/measurementBiological material analysisFreeze-dryingPotassium

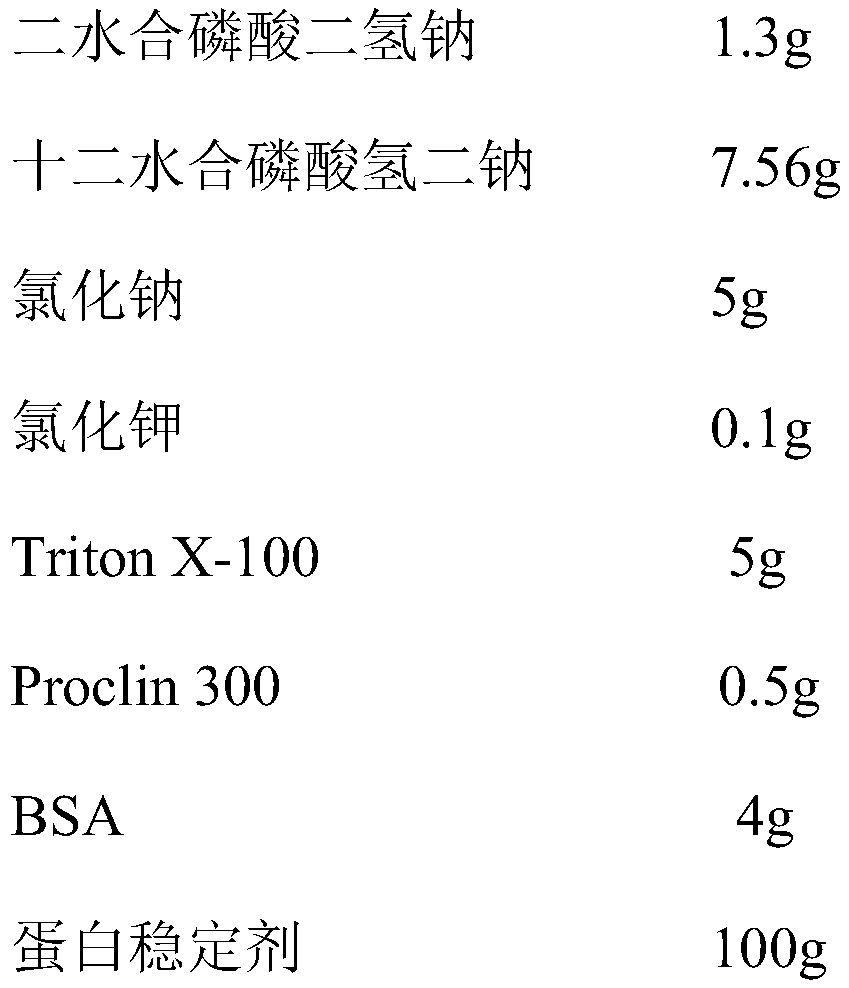

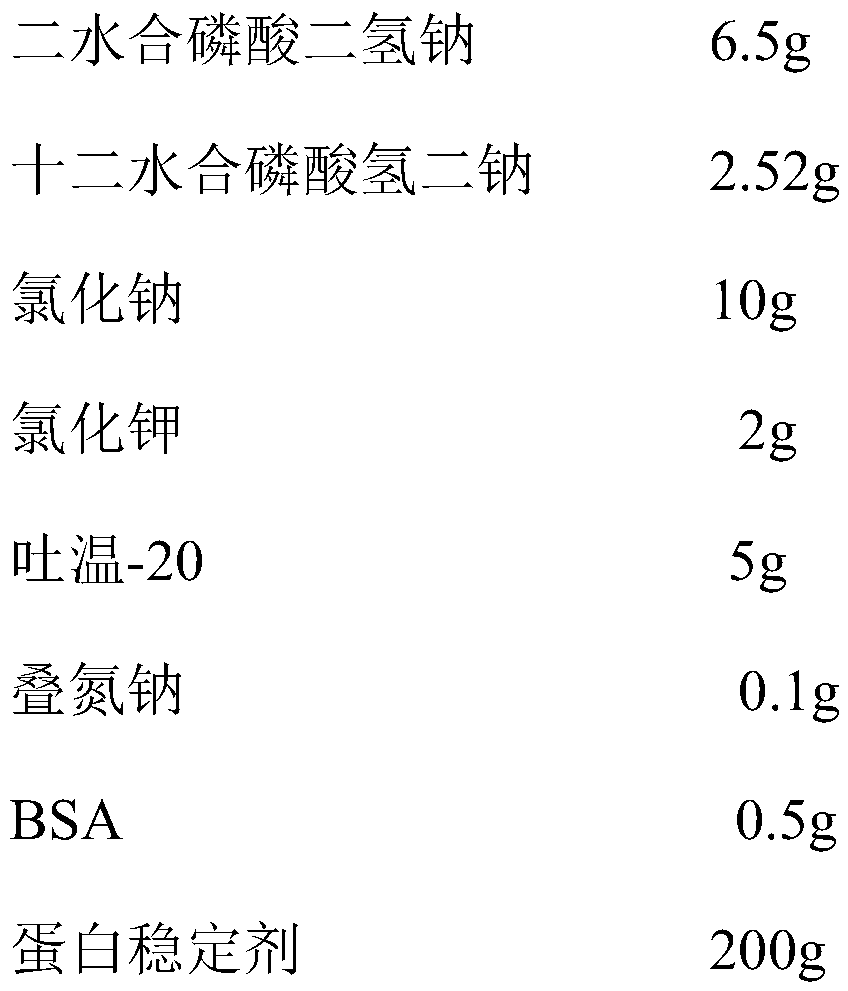

The invention disclsoes a liquid-state NAG (glucosaminidase) correction solution. The correction solution is prepared from the following components: 0.13-13g / L of sodium dihydrogen phosphate dihydrate, 1.26-12.6g / L of disodium hydrogen phosphate dodecahydrate, 0.1-20g / L of sodium chloride, 0.05-3g / L of potassium chloride, 0.5-10g / L of BSA (bull serum albumin), 0.1-10g / L of a surfactant, 0.1-3g / L of a preservative, 50-200g / L of a protein stabilizer and 45U / L of [beta]-N-acetylglucosaminidase; and pH value of the NGA correction solution is 6.0-8.0. With the application of the liquid-state NAG correction solution provided by the invention, the shortcoming of a conventional correction solution which needs to be preserved in a freeze-dried mode is overcome, and preservation conditions of the correction solution are improved, so that item detection in the medical field are facilitated.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

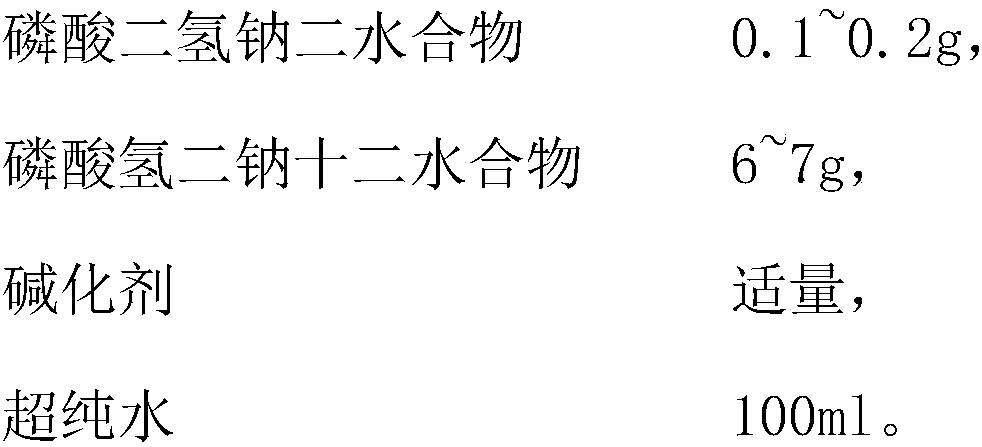

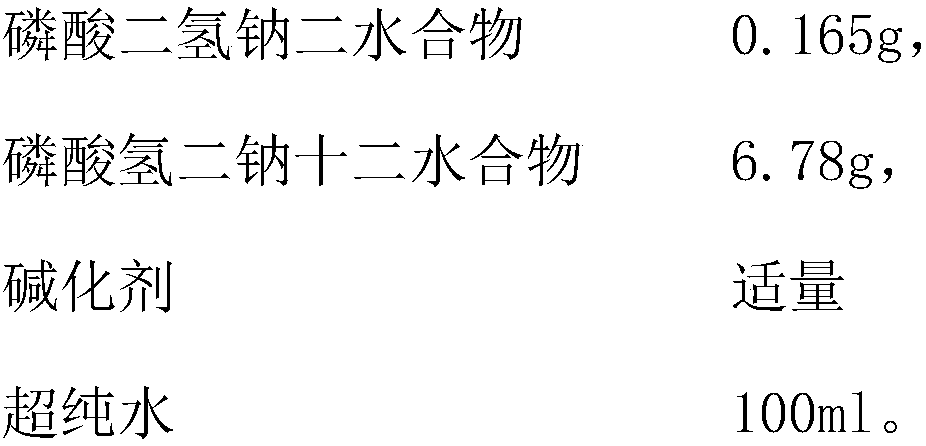

Culture medium for culture expanding and concentration of oocystis species

ActiveCN112574888AIncrease flexibilityEasy to operateUnicellular algaeClimate change adaptationBiotechnologyVitamin B12

The invention provides a culture medium for culture expanding and concentration of oocystis species, wherein the culture medium comprises a nutrient solution A and a nutrient solution B. The nutrientsolution A comprises the following components: NaNO3, sodium dihydrogen phosphate dihydrate, disodium EDTA and ferric chloride hexahydrate. The nutrient solution B comprises the following components:citric acid, ferric ammonium citrate, calcium chloride dihydrate, boric acid, manganese chloride, zinc sulfate, sodium molybdate, copper sulfate, cobalt nitrate, vitamin B1, vitamin B12 and biotin. The invention provides a culture medium for culture expanding and concentration of oocystis species rapid in growth of oocystis species, strong in growth vigor and low in death rate.

Owner:武汉市中易天地物联科技有限公司

Erythrocyte cryopreservation liquid and application thereof

InactiveCN104705287AHigh recovery rateBlood group antigens did not drop significantlyDead animal preservationErythrocyte membraneSodium dihydrogen phosphate dihydrate

The invention discloses an erythrocyte cryopreservation liquid. The erythrocyte cryopreservation liquid comprises 0.8M of potassium citrate monohydrate, 0.4M of sodium dihydrogen phosphate dihydrate, 0.2M of disodium hydrogen phosphate dodecahydrate, and glycerin with the volume concentration of 20-60%. The erythrocyte cryopreservation liquid allows erythrocytes to be disposed at -20DEG C for a long term, and components added to the liquid can improve the water permeability of cell membranes, reduce the formation of intracellular ice crystals and effectively protect erythrocyte membranes; and a thawing protection liquid is added when erythrocytes are thawed at room temperature, so the internal and external physiologic balance of erythrocyte membranes is realized, the rupture of the erythrocyte membranes is avoided, and the purpose of high recovery rate of the erythrocytes is reached.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Preparation method of hydroxyapatite/polylactic acid composite coating on the surface of medical magnesium alloy

InactiveCN103933611BHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681BImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface-modified fluorinated hydroxyapatite coating, specifically: pretreatment of the magnesium alloy substrate, the conversion liquid used is composed of sodium dihydrogen phosphate dihydrate and nitric acid tetrahydrate Calcium-phosphorous coating was obtained by immersing the pretreated substrate sample in the conversion solution for 5h~100h; Alkali fluoride conversion solution is made of sodium hydroxide and sodium fluoride, the concentration of sodium hydroxide is controlled at 3~4g / L, the concentration of sodium fluoride is 4~5g / L, without heat treatment, calcium fluoride phosphorus coating is obtained layer; the calcium fluoride phosphorus coating was heat-treated at 300-350°C for 2-5 hours to prepare fluorinated hydroxyapatite; performance test: the morphology of the FHA coating prepared by combining the heat treatment process was elongated and flake-like and Arranged from the center to the surrounding, the electrochemical test shows that the FHA coating improves the self-corrosion potential of the substrate, and the immersion corrosion test shows that the actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of the FA coating.

Owner:TONGJI UNIV

Spermidine synthetase activity determination reagent kit and method

InactiveCN109541052AHigh precisionHigh detection sensitivityComponent separationSodium bicarbonateFluorescence

The invention discloses a spermidine synthetase activity determination reagent kit and method. The reagent kit comprises a reagent 1 (sodium hydrogen phosphate heptahydrate, sodium dihydrogen phosphate dehydrate, water), a reagent 2 (sodium hydrogen phosphate heptahydrate, sodium dihydrogen phosphate dihydrate, beta-mercaptoethanol, EDTA, phosphopyridoxal, water), a reagent 3 (a reagent 2, putrescine, decarbocylated S-ademetionine), a reagent 4 (perchloric acid, water), a reagent 5 (sodium hydroxide, water), a reagent 6 (saturated sodium bicarbonate), a reagent 7 (dansyl chloride, acetone), areagent 8 (ammonia), a reagent 9 (perchloric acid, water) and a reagent 10 (spermidine standard). The principle of the method is to catalyze putrescine to produce spermide through spermidine synthetase, and then to make spermidine and dansyl chloride react under an alkaline condition to produce a derivative with fluorescence, through separation by a high-efficiency liquid chromatography, a fluorescence detector is used to determine the spermidine production amount, and thus, the activity of the spermidine synthetase is further measured.

Owner:SUZHOU COMIN BIOTECH

Anti-blushing agent for copper-plated surface of gouging carbon rod as well as preparation method and application of anti-blushing agent

PendingCN114807919AWith anti-tarnish abilityEasy to makeMetallic material coating processesOrganic compoundSodium sulfate

The invention provides a gouging carbon rod copper plating surface anti-blushing agent and a preparation method and application thereof, and belongs to the technical field of chemical agents.The anti-blushing agent is prepared from, by weight, 0.2-0.4 g of a sulfydryl organic compound, 0.4-0.6 g of organic phosphonic acid, 0.2-1 g of ethylene diamine tetraacetic acid, 0.2-0.4 g of sodium sulfate, 0.2-0.4 g of sodium silicate, 0.2-0.4 g of sodium dihydrogen phosphate dihydrate, 0.2-0.4 g of sodium chloride, 0.2-0.4 g of sodium chloride, 0.2-0.4 g of sodium chloride, 0.2-0.4 g of sodium chloride, 0.2-0.4 g of sodium chloride, 0.2-0.4 g of sodium chloride and the balance water. 5-10 g of absolute ethyl alcohol and 1000 g of water; according to the anti-tarnishing agent disclosed by the invention, a protective film with anti-tarnishing capability can be generated on the surface of a gouging carbon rod copper-plated product; the copper-plated carbon arc gouging carbon rod subjected to surface treatment is not rusted after being subjected to a damp-heat experiment for 240 hours, has no obvious appearance change after being placed indoors for 3 months, and is simple in preparation and application process, safe and environment-friendly.

Owner:邓茜丹 +1

A tophi dispersant and preparation method thereof

InactiveCN105326857BEffective dissolutionEasy to useInorganic phosphorous active ingredientsInorganic non-active ingredientsSodium dihydrogen phosphate dihydrateMedicinal chemistry

Owner:叶川 +4

Special culture medium for producing concentrated oocystis and culture method thereof

PendingCN112457995AGrow fastFast growth rateUnicellular algaeWaste water treatment from animal husbandryBiotechnologySodium acetate

The invention relates to the technical field of microalgae culture, and discloses a special culture medium for producing concentrated oocystis. The special culture medium comprises a component A and acomponent B, the component A comprises glucose, sodium acetate, sodium nitrate, urea, ammonium chloride, sodium dihydrogen phosphate dihydrate, disodium EDTA and ferric chloride hexahydrate, and thecomponent B comprises citric acid, ammonium ferric citrate, calcium chloride dihydrate, manganese chloride tetrahydrate, zinc sulfate heptahydrate, sodium molybdate dihydrate, copper sulfate pentahydrate, cobalt nitrate hexahydrate, vitamin B1, vitamin B12 and biotin. The special culture medium has the advantages that an oocystis seed solution is inoculated after the component A and the componentB are mixed, the oocystis can rapidly grow during fermentation culture, the concentrated oocystis solution is produced, and the oocystis culture medium has the effects of high growth rate and high success rate of enlarged culture. Glycerin, maltotriose and glycine are added into the special culture medium, and in the culture process, the oocystis with an obvious inhibition effect on moss can be obtained through domestication under the induction of various factors.

Owner:武汉市中易天地物联科技有限公司

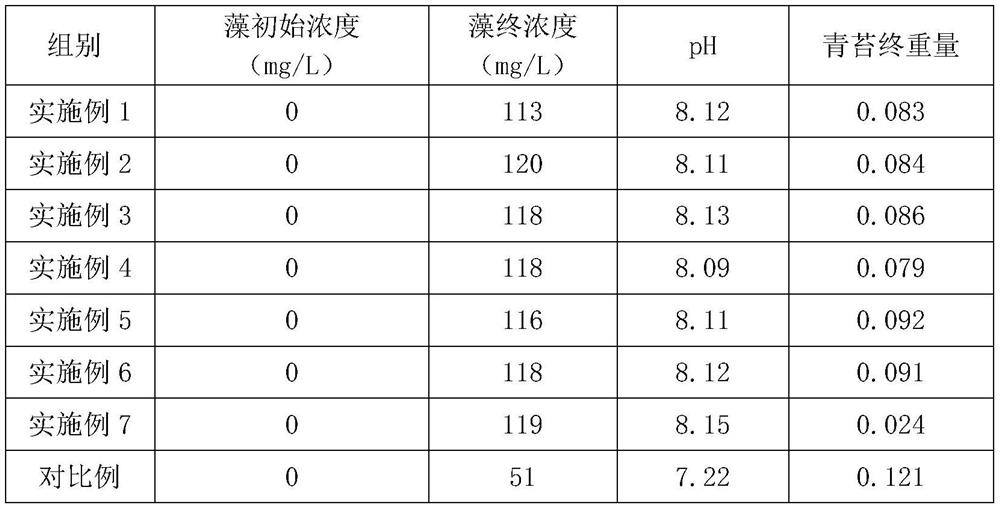

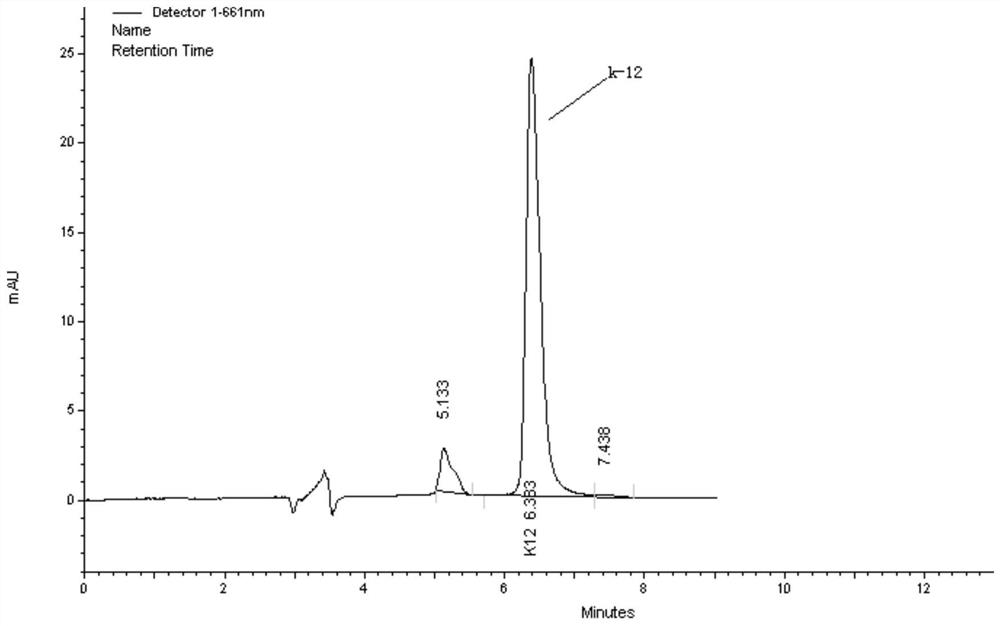

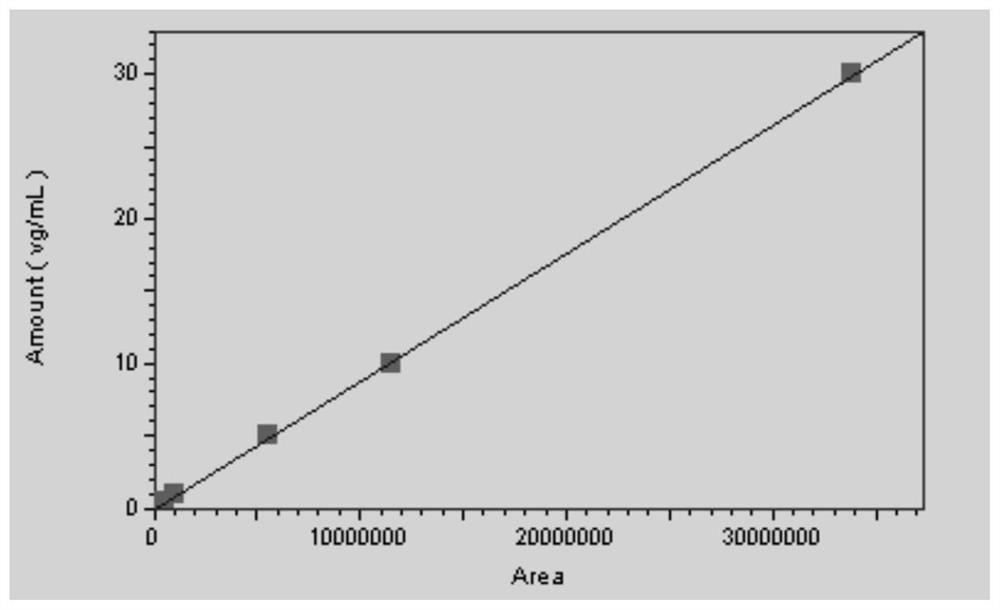

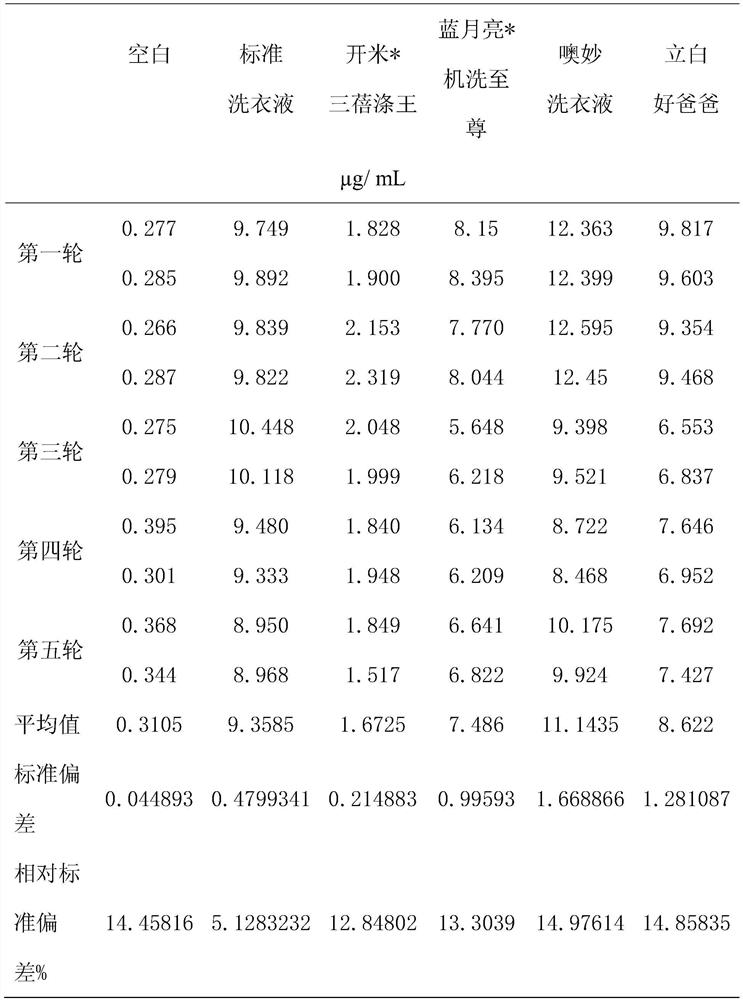

A liquid chromatography method for detecting detergent residues on fabrics

ActiveCN109541070BClose to the real effectImprove accuracyComponent separationActive agentVolumetric flask

The invention provides a method for detecting detergent residues on fabrics by liquid chromatography, which establishes an experimental model to directly detect detergent residues on fabrics, and has the effects of high accuracy, strong reliability and wide applicability. The steps of the method of the present invention are: 1) preparation of diluent: diluent: 1000mL volume containing sodium dihydrogen phosphate dihydrate (NaH 2 PO 4 2H 2 O) 50g, 6.8mL sulfuric acid (ρ=1.84g / mL); 2) Preparation of derivatization reagent methylene blue solution: Weigh 10-100mg methylene blue in a 1000mL volumetric flask, and dilute to the scale with diluent for later use; 3) Anion surface Preparation of active agent standard solution: Weigh 10-100mg of anionic surfactant standard sample into a 1000mL volumetric flask, dilute it to the mark with ultrapure water, and use it as mother liquor to prepare standard solutions of different concentrations for later use; 4) Draw the anionic surfactant Agent correlation curve: 5) Sample detection.

Owner:上海开米科技有限公司

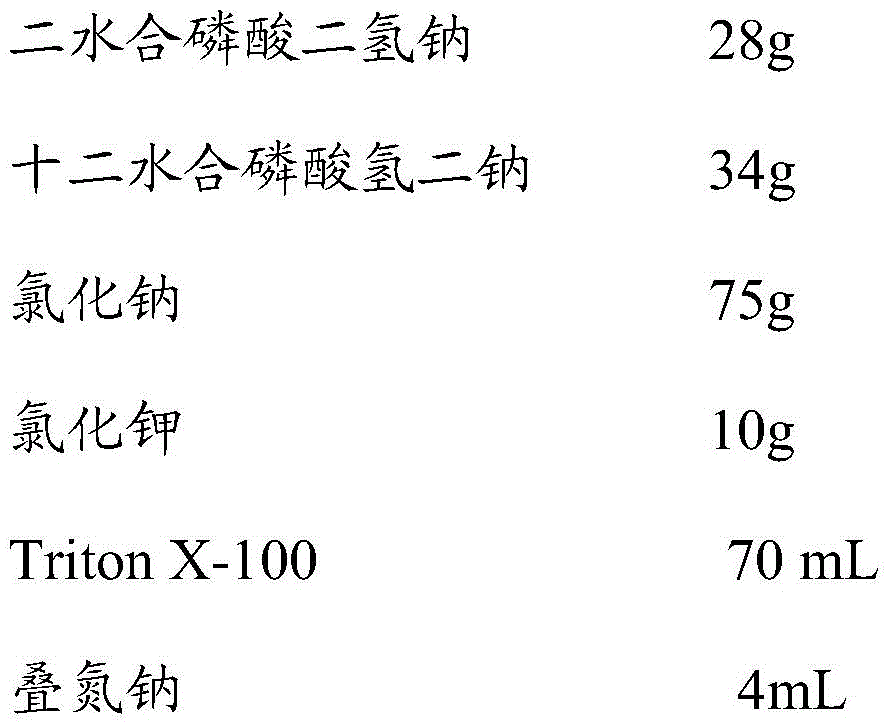

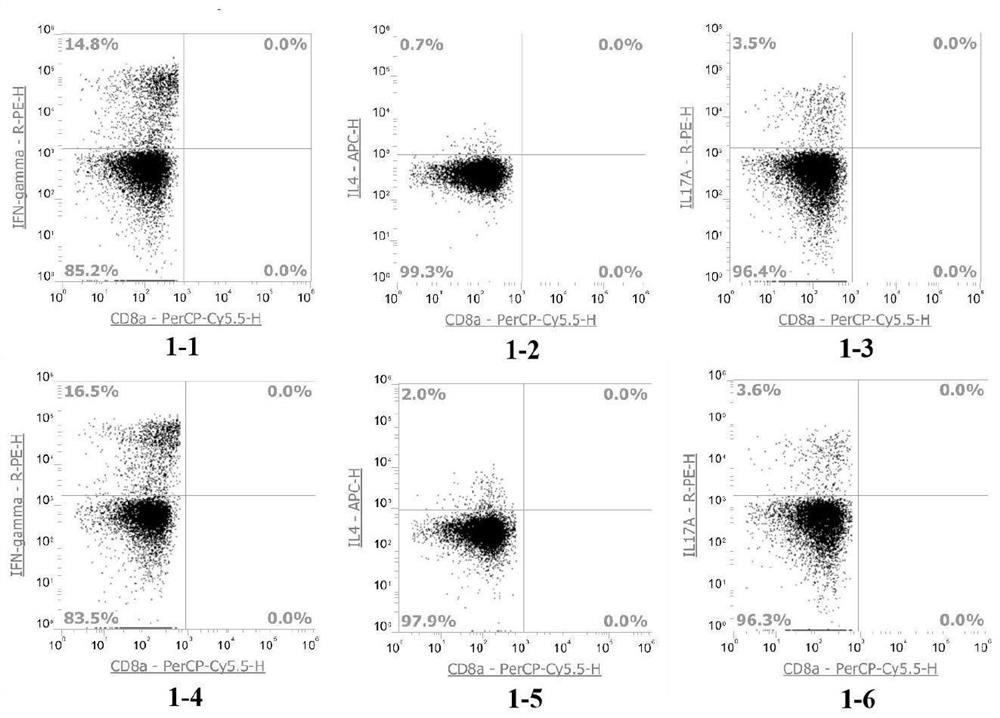

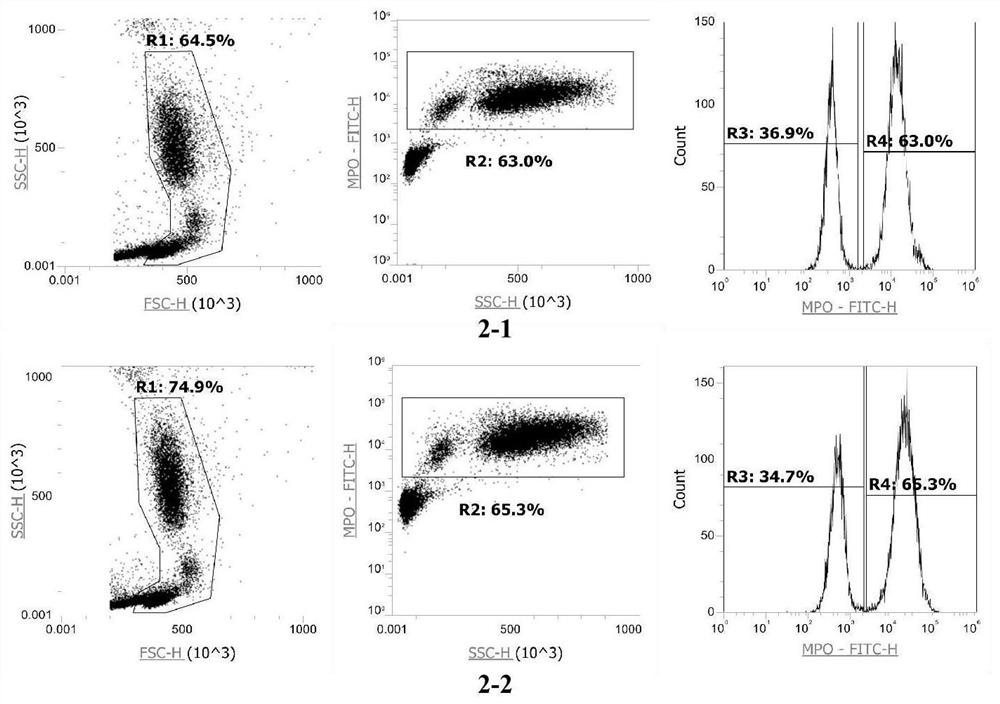

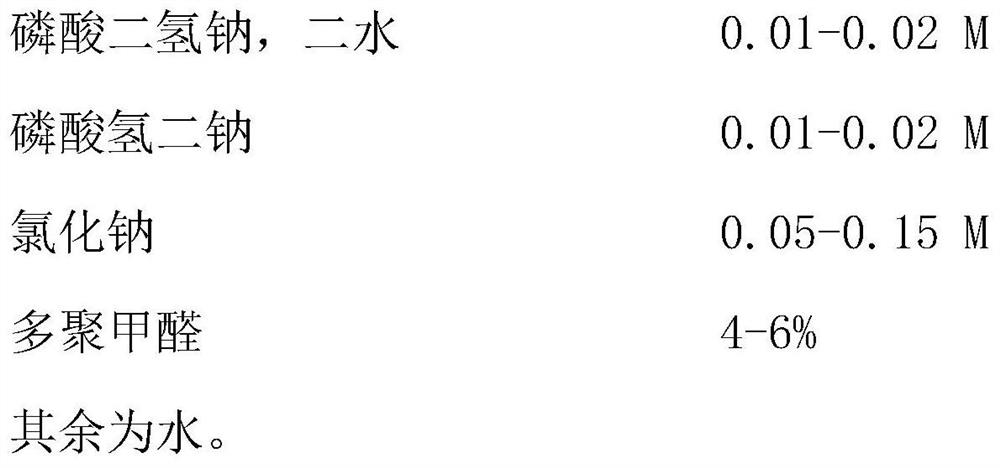

Fixing permeabilization wash buffer and preparation method thereof

PendingCN112229696AReduce testing costsImprove stabilityPreparing sample for investigationBiological material analysisSodium dihydrogen phosphate dihydrateMagnetic stirrer

The invention discloses a fixing agent. The fixing agent comprises 0.01-0.02 M of sodium dihydrogen phosphate dihydrate, 0.01-0.02 M of sodium dihydrogen phosphate, 0.05-0.15 M of sodium chloride, 4-6% of paraformaldehyde, and the balance of water. Further, the pH value of the fixing agent is 7.0-7.4. A preparation method of the fixing agent comprises the following steps: 1, accurately weighing sodium dihydrogen phosphate dihydrate, disodium hydrogen phosphate and sodium chloride into a beaker, adding a proper amount of ultrapure water, and uniformly stirring and mixing for sufficiently dissolving; 2, accurately weighing paraformaldehyde into a beaker, adding paraformaldehyde into the solution prepared in step 1, heating and stirring with a magnetic stirrer, controlling the temperature tobe 60 DEG C or below until paraformaldehyde is completely dissolved, and adjusting the pH value to 7.0-7.4 with a 10N NaOH solution; and 3, after the pH is adjusted, adding ultrapure water into the beaker by using a measuring cylinder, fixing the volume to a preparation volume, uniformly stirring and mixing, and storing in a dark place at room temperature. The advantages of good detection specificity and sensitivity, low detection cost, high stability, simple operation, high repeatability, and guaranteeing of the reliability of the result are achieved.

Owner:杭州联科生物技术股份有限公司

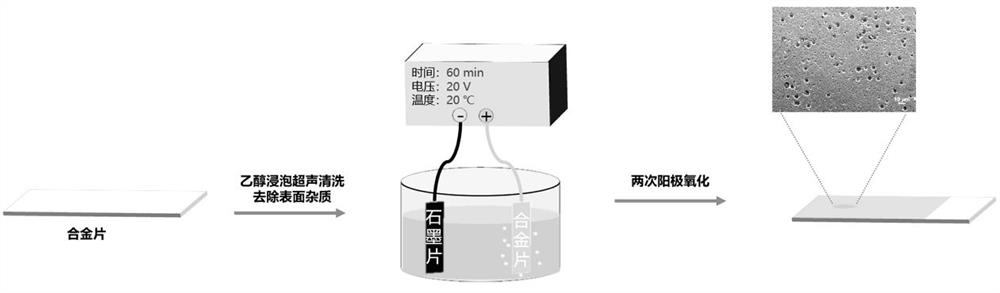

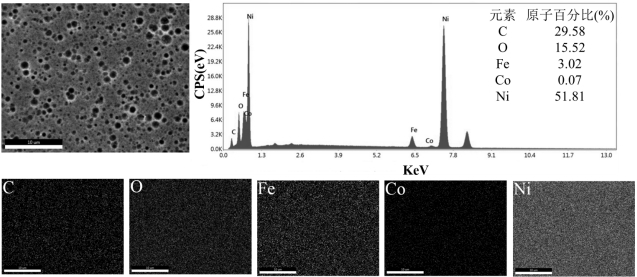

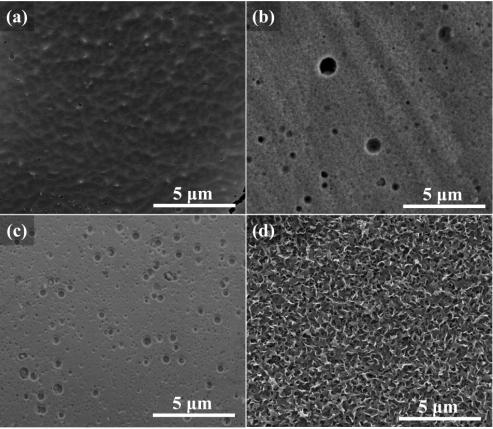

Preparation method of micro-nano holes in surface of nickel-containing iron-chromium alloy

PendingCN114032595AEfficient arrangementImprove universalityAnodisationMicro nanoSodium dihydrogen phosphate dihydrate

The invention discloses a preparation method of micro-nano holes in the surface of a nickel-containing iron-chromium alloy. The method comprises the following steps that firstly, the alloy is pretreated to remove surface impurities; the surface of the alloy is subjected to first-time anodic oxidation treatment, the alloy serves as an anode, a graphite sheet serves as a cathode, first-time anodic oxidation is conducted, and then the alloy is cleaned with ethyl alcohol and dried for use; and then, secondary anodic oxidation treatment is conducted on the surface of the alloy subjected to primary anodic oxidation treatment, the alloy serves as an anode, a graphite flake serves as a cathode, secondary anodic oxidation is conducted in a sodium dihydrogen phosphate dihydrate solution, then ethyl alcohol is used for cleaning, and the flexible alloy surface with obvious micro-nano holes is obtained after drying. According to the method, the alloy surface is subjected to flexible treatment by adopting a two-time anodic oxidation method, the universality of the anodic oxidation alloy is higher, micro-nano holes in the surface of the nickel-iron-chromium-containing alloy are ideally arranged through two-time anodic oxidation, and application of the nickel-iron-chromium-containing alloy in the fields of 3C, electronics and the like is promoted.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

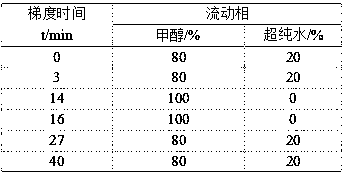

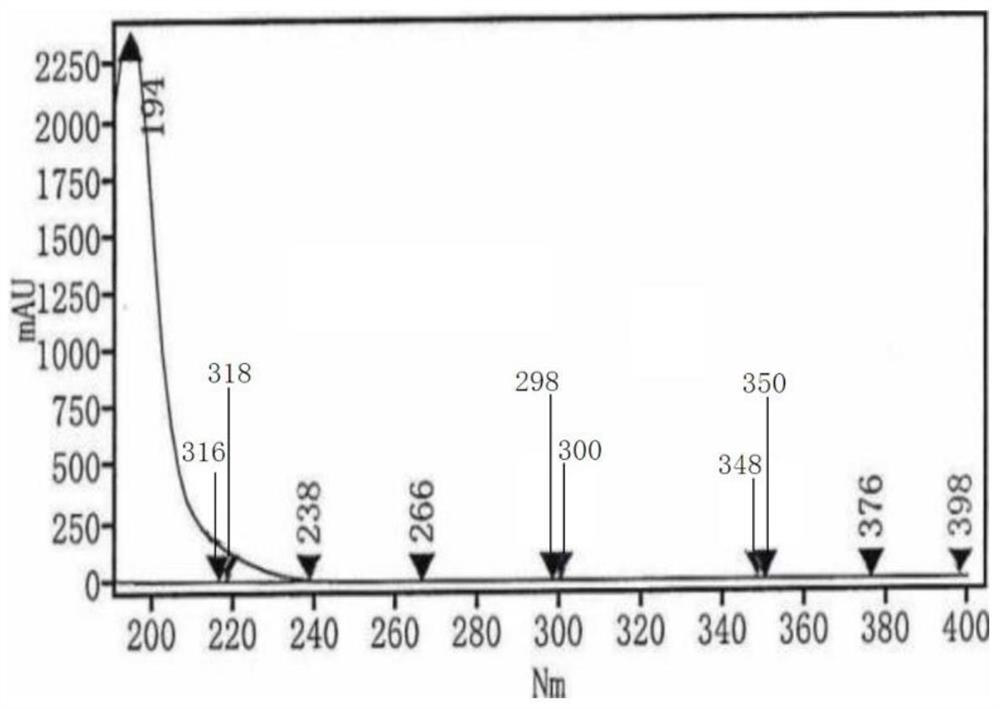

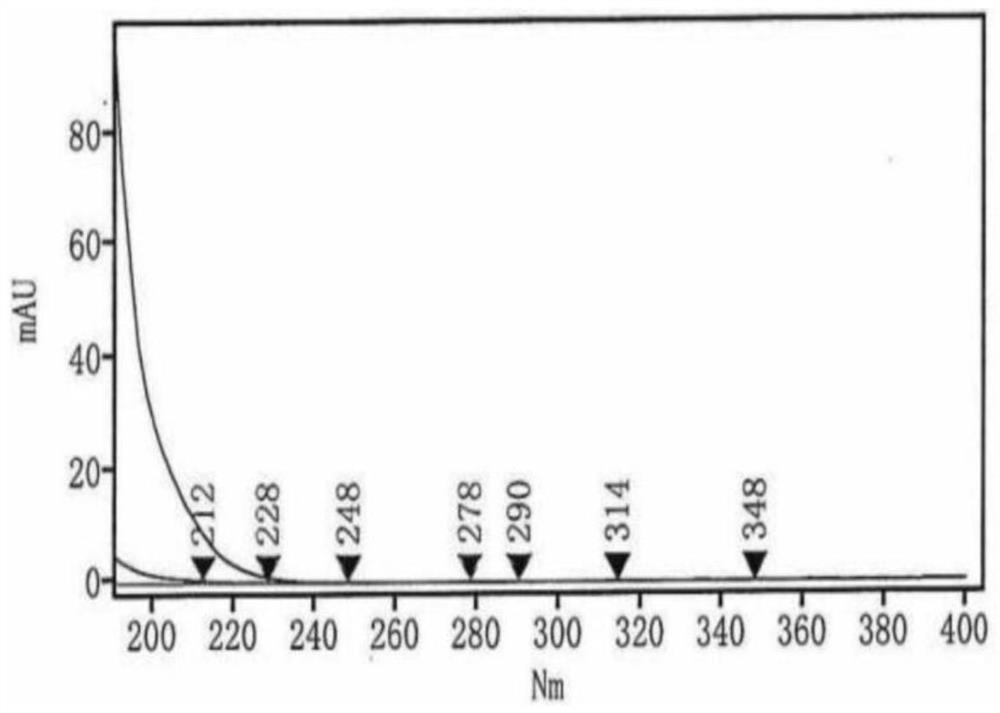

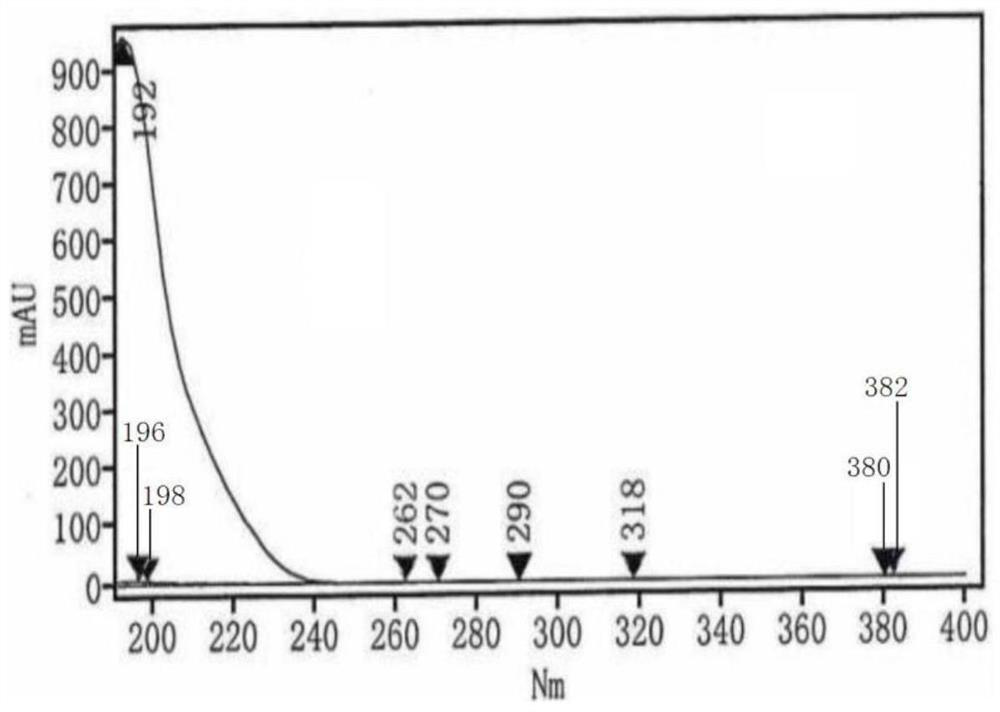

HPLC (High Performance Liquid Chromatography) test method for related substances in L-prolinamide

The invention provides an HPLC (High Performance Liquid Chromatography) test method for related substances in L-prolinamide, and belongs to the technical field of column chromatography test or analysis materials. The L-prolinamide related substance is an impurity introduced or generated by degradation in a synthesis process of L-prolinamide, a mobile phase is a solution obtained by adding water to dissolve sodium octanesulfonate and sodium dihydrogen phosphate dihydrate and then adding acetonitrile to uniformly mix, a high performance liquid chromatography is adopted, octadecylsilane chemically bonded silica is used as a filler to perform chromatographic column separation, and the content of the L-prolinamide related substance is measured. The mobile phase is used as a solvent to perform isocratic elution on impurities. The method is applied to impurity determination of related substances of L-prolinamide, and has the advantages of being stable in chromatographic condition system, good in linearity, high in precision, high in chromatographic condition sensitivity, good in specificity, stable in determination solution within 35 hours and the like.

Owner:ZHEJIANG GUOBANG PHARMA

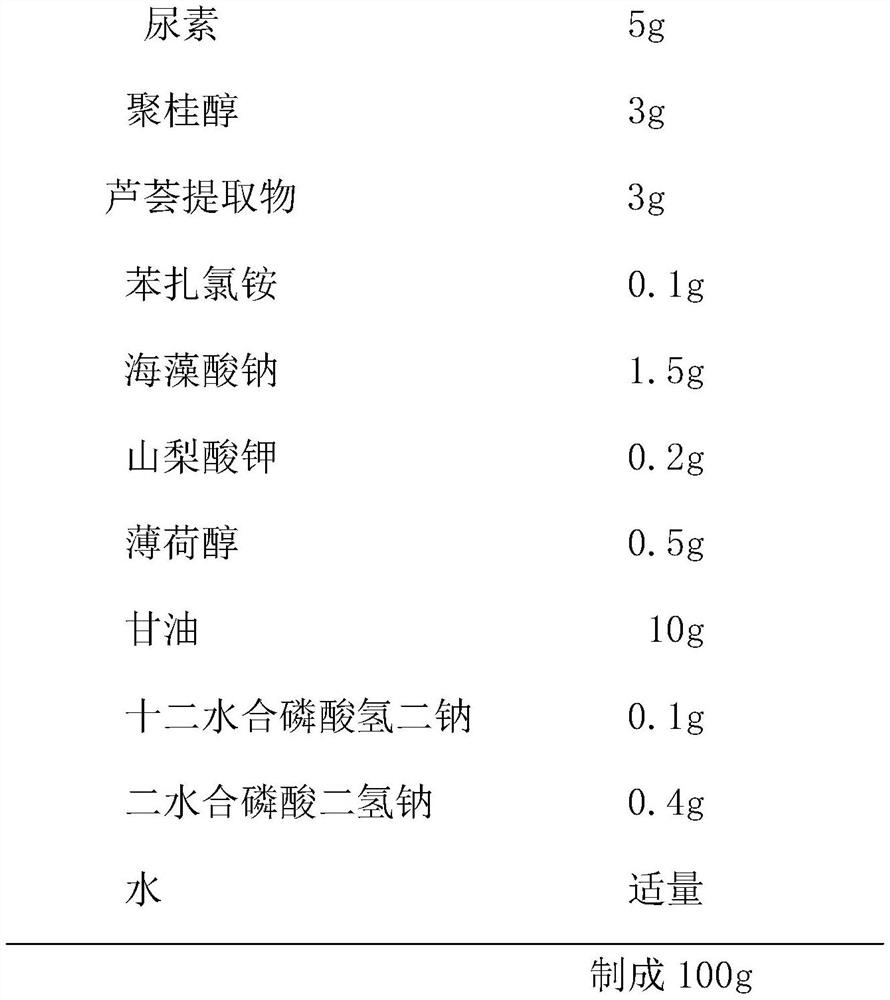

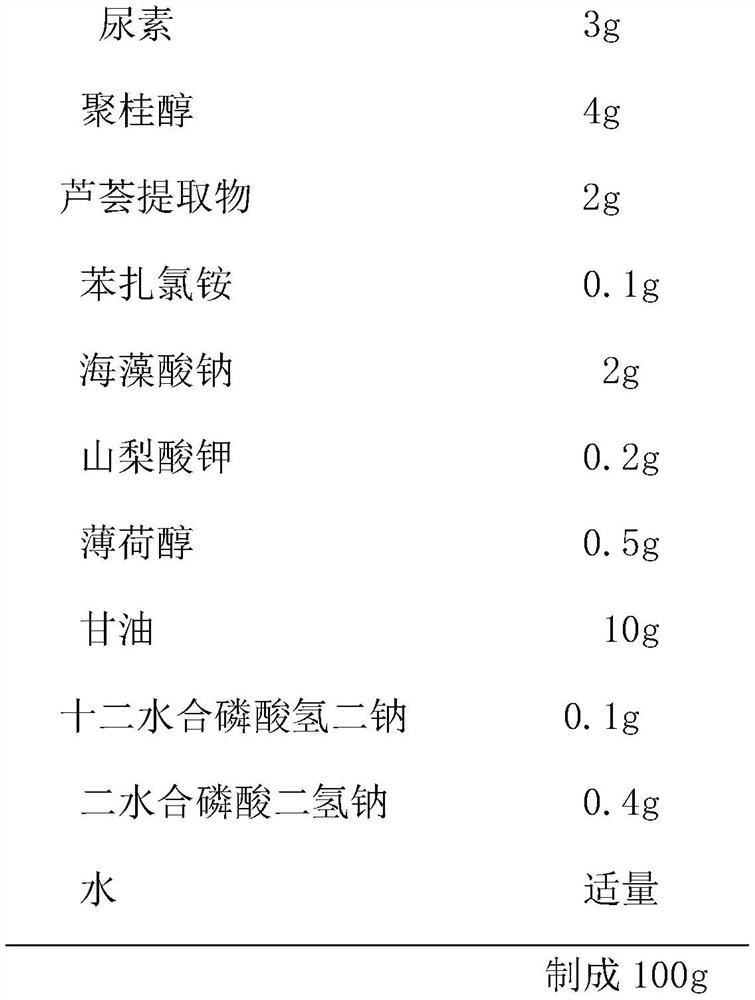

Lauromacrogol external gel and preparation method thereof

The invention relates to a lauromacrogol gel for external use and a preparation method thereof. The components include urea, lauromacrogol, aloe extract, benzalkonium chloride, sodium alginate, potassium sorbate, menthol, glycerin, dodecahydrate Disodium hydrogen phosphate, sodium dihydrogen phosphate dihydrate and purified water. The feature of the present invention is to combine lauromacrogol, which has rapid antipruritic and pain relief, anti-inflammatory and detumescent effects, and aloe vera extract, which has astringent and skin repairing effects, and is used in the form of a gel film to treat 1-2 degree burns and mosquitoes Bites and bruises patients; this is beyond the reach of similar drugs for the treatment of burns and mosquito bites, and there is no similar treatment of anti-inflammatory products or related inventions.

Owner:SHAANXI TIANYU PHARMA

A kind of liquid nag calibration solution and preparation method thereof

ActiveCN106755281BEasy to prepareEasy to useMicrobiological testing/measurementBiological material analysisFreeze-dryingPotassium

The invention disclsoes a liquid-state NAG (glucosaminidase) correction solution. The correction solution is prepared from the following components: 0.13-13g / L of sodium dihydrogen phosphate dihydrate, 1.26-12.6g / L of disodium hydrogen phosphate dodecahydrate, 0.1-20g / L of sodium chloride, 0.05-3g / L of potassium chloride, 0.5-10g / L of BSA (bull serum albumin), 0.1-10g / L of a surfactant, 0.1-3g / L of a preservative, 50-200g / L of a protein stabilizer and 45U / L of [beta]-N-acetylglucosaminidase; and pH value of the NGA correction solution is 6.0-8.0. With the application of the liquid-state NAG correction solution provided by the invention, the shortcoming of a conventional correction solution which needs to be preserved in a freeze-dried mode is overcome, and preservation conditions of the correction solution are improved, so that item detection in the medical field are facilitated.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com