Special culture medium for producing concentrated oocystis and culture method thereof

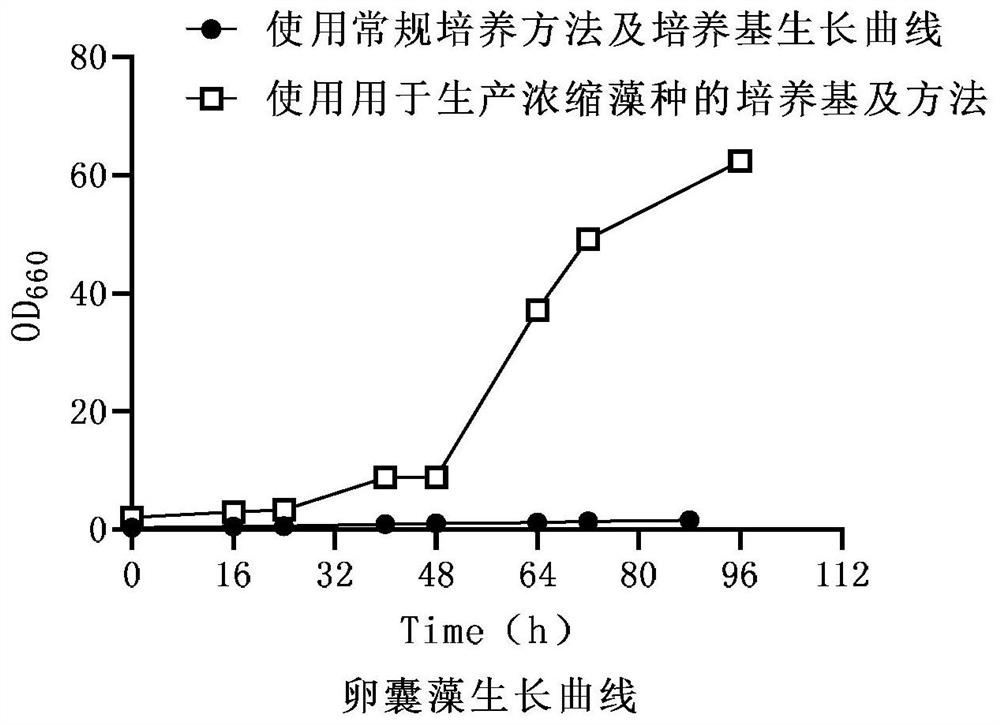

A technology of oocystis and culture medium, which is applied in the field of microalgae cultivation, can solve the problems of low cultivation efficiency, low concentration of algae liquid, influence on use, etc., and achieves the effect of high success rate of expanded cultivation and fast growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

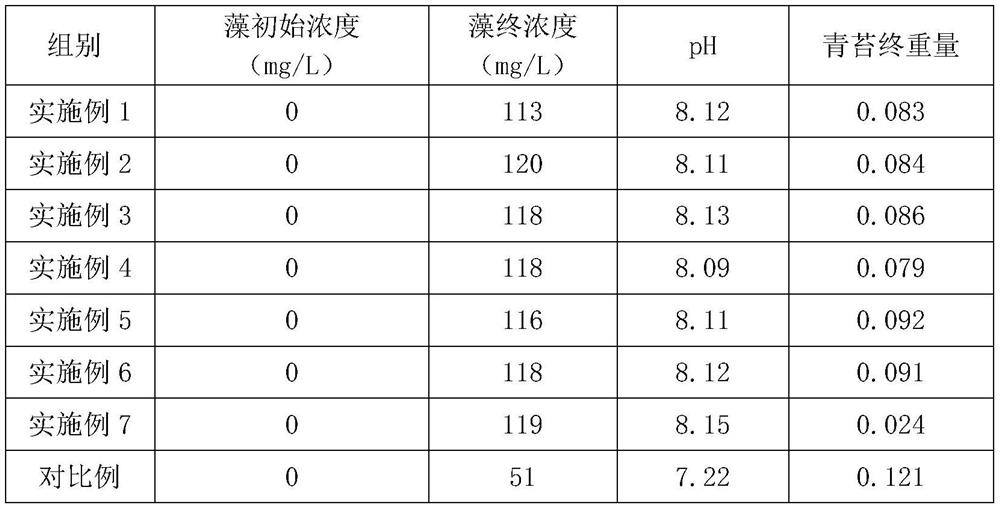

Embodiment 1

[0019] Embodiment 1: A kind of special medium for producing concentrated oocysts, including A component and B component, A component includes glucose 15g / L, sodium acetate 5g / L, sodium nitrate 5g / L, urea 1g / L, Ammonium Chloride 2g / L, Sodium Dihydrogen Phosphate Dihydrate 0.1g / L, Disodium EDTA 0.1g / L, Ferric Chloride Hexahydrate 0.2g / L. The preparation method of component A is as follows: take each substance in component A, dissolve it in water in a fermenter in proportion, adjust the pH with NaOH solution within the range of 7.5±0.2, and sterilize at 121°C for 20 minutes.

[0020] Component B includes citric acid 3g / L, ferric ammonium citrate g / L, calcium chloride dihydrate 20g / L, manganese chloride tetrahydrate 0.5g / L, zinc sulfate heptahydrate 0.2g / L, molybdic acid dihydrate Sodium 0.3g / L, copper sulfate pentahydrate 0.5g / L, cobalt nitrate hexahydrate 0.3g / L, vitamin B1 0.1g / L, vitamin B12 0.001g / L, biotin 0.003g / L. The preparation method of component B is as follows, take...

Embodiment 2

[0023] Embodiment 2: A kind of special medium for producing concentrated oocysts, including A component and B component, A component includes glucose 55g / L, sodium acetate 10g / L, sodium nitrate 10g / L, urea 3g / L, Ammonium Chloride 5g / L, Sodium Dihydrogen Phosphate Dihydrate 0.4g / L, Disodium EDTA 0.3g / L, Ferric Chloride Hexahydrate 0.4g / L. The preparation method of component A is as follows: take each substance in component A, dissolve it in water in a fermenter in proportion, adjust the pH with NaOH solution, maintain it within the range of 7.5±0.2, and sterilize at 121°C for 20 minutes.

[0024] Component B includes citric acid 8g / L, ferric ammonium citrate 8g / L, calcium chloride dihydrate 50g / L, manganese chloride tetrahydrate 3g / L, zinc sulfate heptahydrate 0.6g / L, sodium molybdate dihydrate 0.8g / L, copper sulfate pentahydrate 0.8g / L, cobalt nitrate hexahydrate 0.6g / L, vitamin B1 0.3g / L, vitamin B12 0.01g / L, biotin 0.005g / L. The preparation method of component B is as foll...

Embodiment 3

[0027] Embodiment 3: A kind of special medium for producing concentrated oocysts, the difference from Example 1 is that when the special medium for producing concentrated oocysts is used to cultivate oocysts, each material in the A component is taken , dissolve in water in proportion in the fermenter, adjust the pH with NaOH solution, maintain it within the range of 7.5±0.2, sterilize at 121°C for 20min, cool to 30°C, add the filter-sterilized component B into the fermenter , inoculating the oocyst seed liquid in a fermenter, cultivating at 25-35° C., cultivating until the fermentation biomass reaches 35000-50000 mg / L, and ending the fermentation to obtain concentrated oocysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com