High-temperature resistant optical fiber

A technology of high temperature resistance and optical fiber, which is applied in the field of high temperature resistant optical fiber, which can solve the problems of unusable optical fiber and achieve the effect of strengthening luminous function and good communication stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

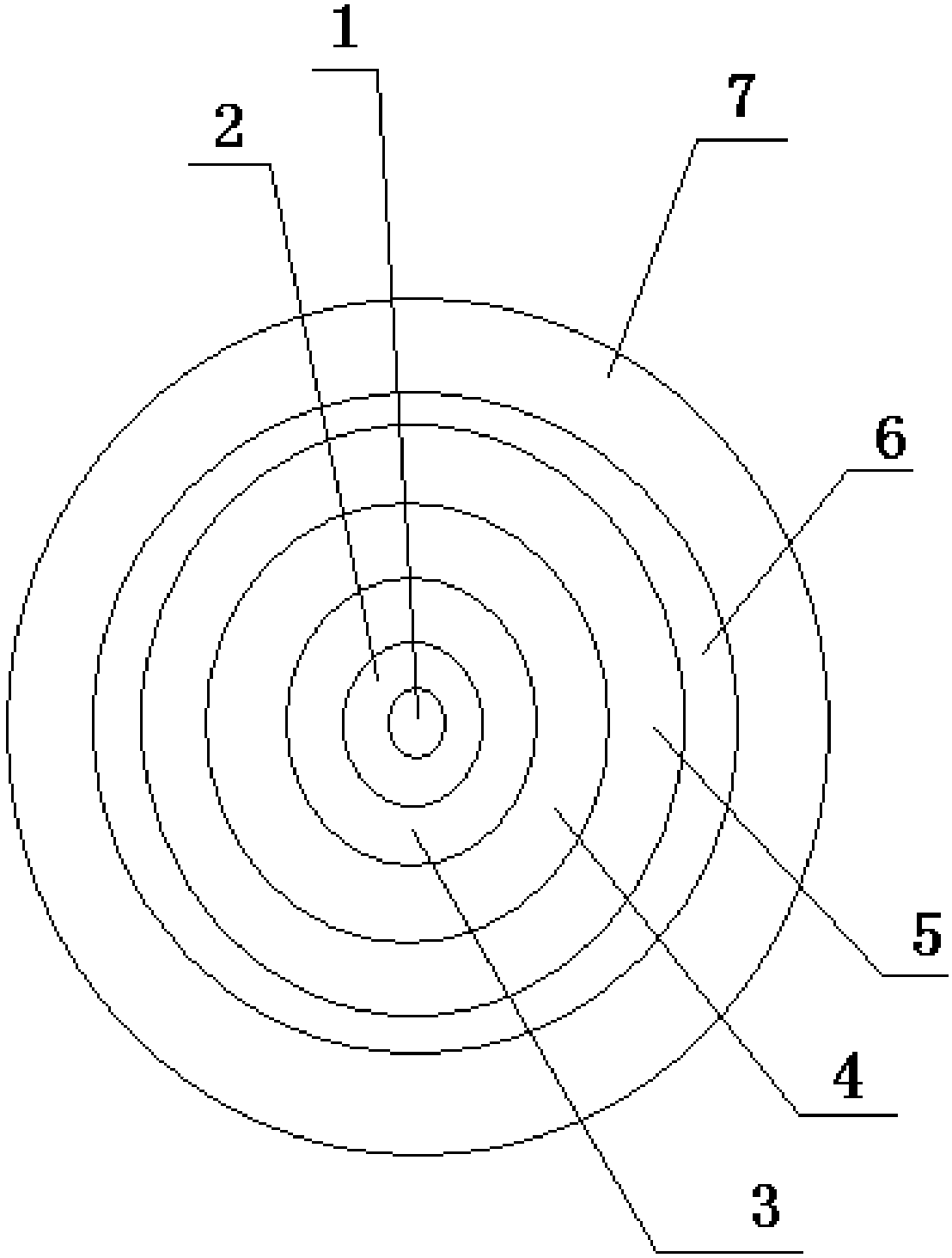

[0009] The high temperature resistant optical fiber includes glass core layer (1), glass cladding layer (2), paraffin layer (3), metal coating layer (4), high temperature resistant outer sheath layer (5), stainless steel tube layer ( 6), mica isolation layer (7); the high temperature resistant outer sheath (5), is made up of the following components by weight, deionized water 200-230 parts, sodium chloride 15-25 parts, defoamer 5- 7 parts, 8-14 parts of leveling agent, 3-5 parts of emulsifier, 5-10 parts of ethylene glycol, 260-300 parts of polymer resin emulsion, 1-2 parts of thickener, 1-4 parts of hydrophobic agent, 3-6 parts of PVC, 5-9 parts of bamboo powder, 80-100 parts of silicon dioxide.

[0010] The glass cladding (2) is nylon 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com