Microspherical particles

A spherical particle and tiny technology, which is applied in the fields of dentistry, oral care, and cosmetic preparations, etc., can solve the problems of disintegration of granules and decline in massage effect, and achieve high washing effect and excellent massage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

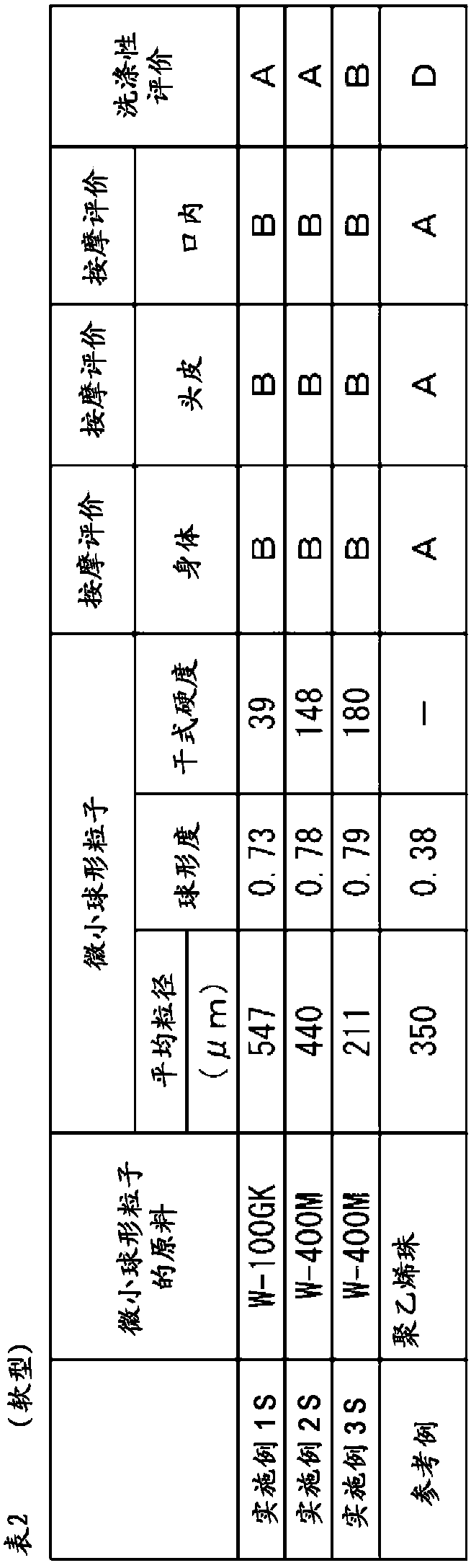

Examples

Embodiment 1H

[0079] 0.5 kg of powdered cellulose W-100G (manufactured by Nippon Paper Co., Ltd., with an average particle size of 35 μm, an average degree of polymerization of 450, an apparent specific gravity of 0.29 g / ml, and an angle of repose of 58°) was placed in a centrifugal roll In the granulator CF-360N (manufactured by Freund Corp.), granulation was performed by spraying 1.25 kg of water for 100 minutes at a slit air volume of 200 to 300 L / min while rotating the rotary disc. The generated particles were fluidized-dried to obtain fine spherical particles with an average particle diameter of 650 μm, a sphericity of 0.85, a dry hardness of 452 g, and an apparent specific gravity of 0.65 g / ml.

Embodiment 2H

[0081] 1 kg of powdered cellulose W-400G (manufactured by Nippon Paper Co., Ltd., with an average degree of polymerization of 150, an average particle size of 24 μm, an apparent specific gravity of 0.48 g / ml, and an angle of repose of 52°) was loaded into the centrifugal rolling granulator In an apparatus CF-360N (manufactured by Freund Corp.), granulation was performed by spraying 1.2 kg of water for 100 minutes at a slit air volume of 220 L / min while rotating a rotary disc. The generated particles were fluidized-dried to obtain fine spherical particles with an average particle diameter of 340 μm, a sphericity of 0.84, a dry hardness of 247 g, and an apparent specific gravity of 0.83 g / ml.

Embodiment 3H

[0083] During the 100-minute granulation process, the number of sprays of water was increased. In addition, the same operation was performed as in Example 2H to obtain an average particle diameter of 490 μm, a sphericity of 0.87, a dry hardness of 490 g, and an apparent specific gravity of 490 μm. 0.85g / ml tiny spherical particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com