Motorized joint for programmable moving machine

A mobile and maneuverable technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

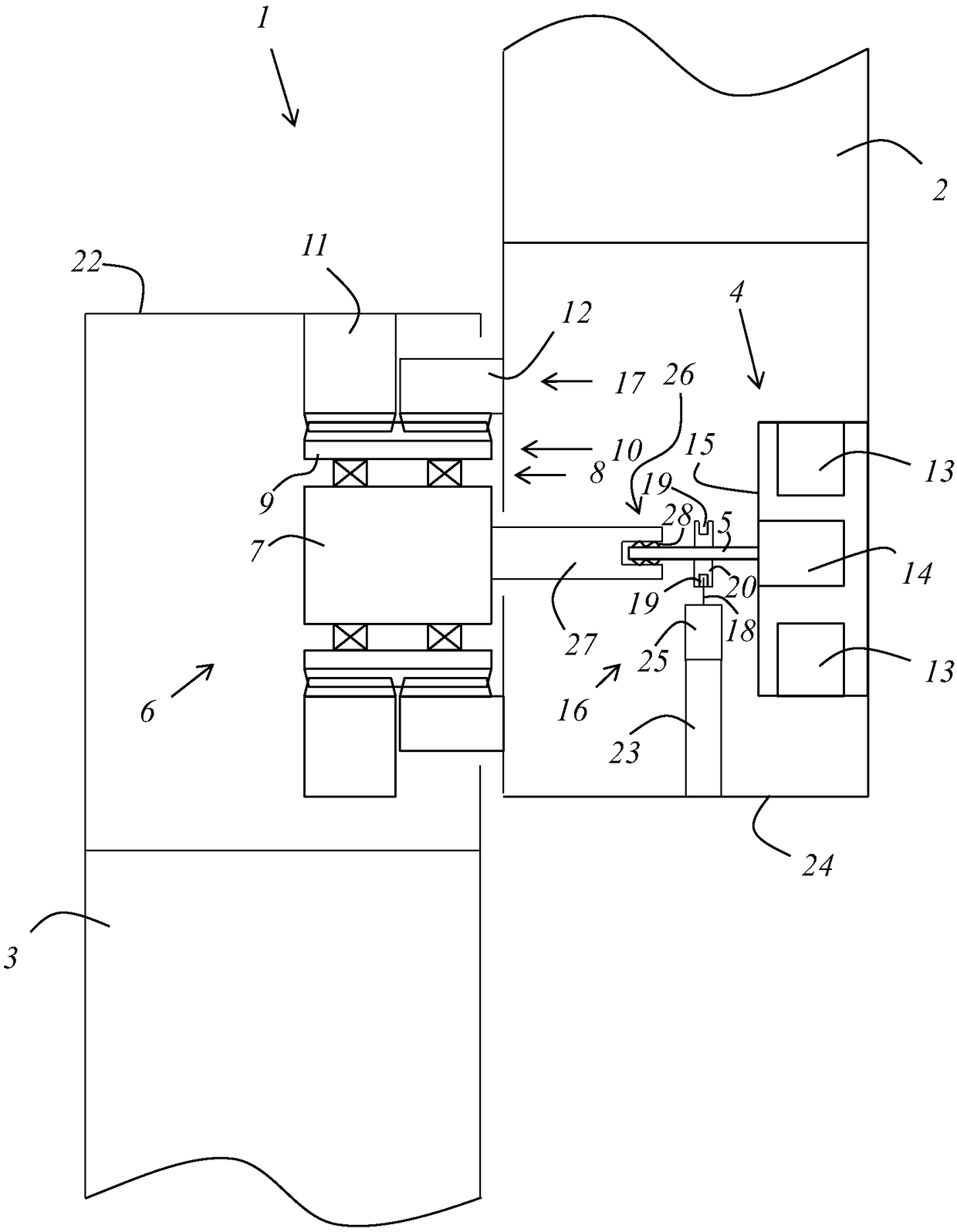

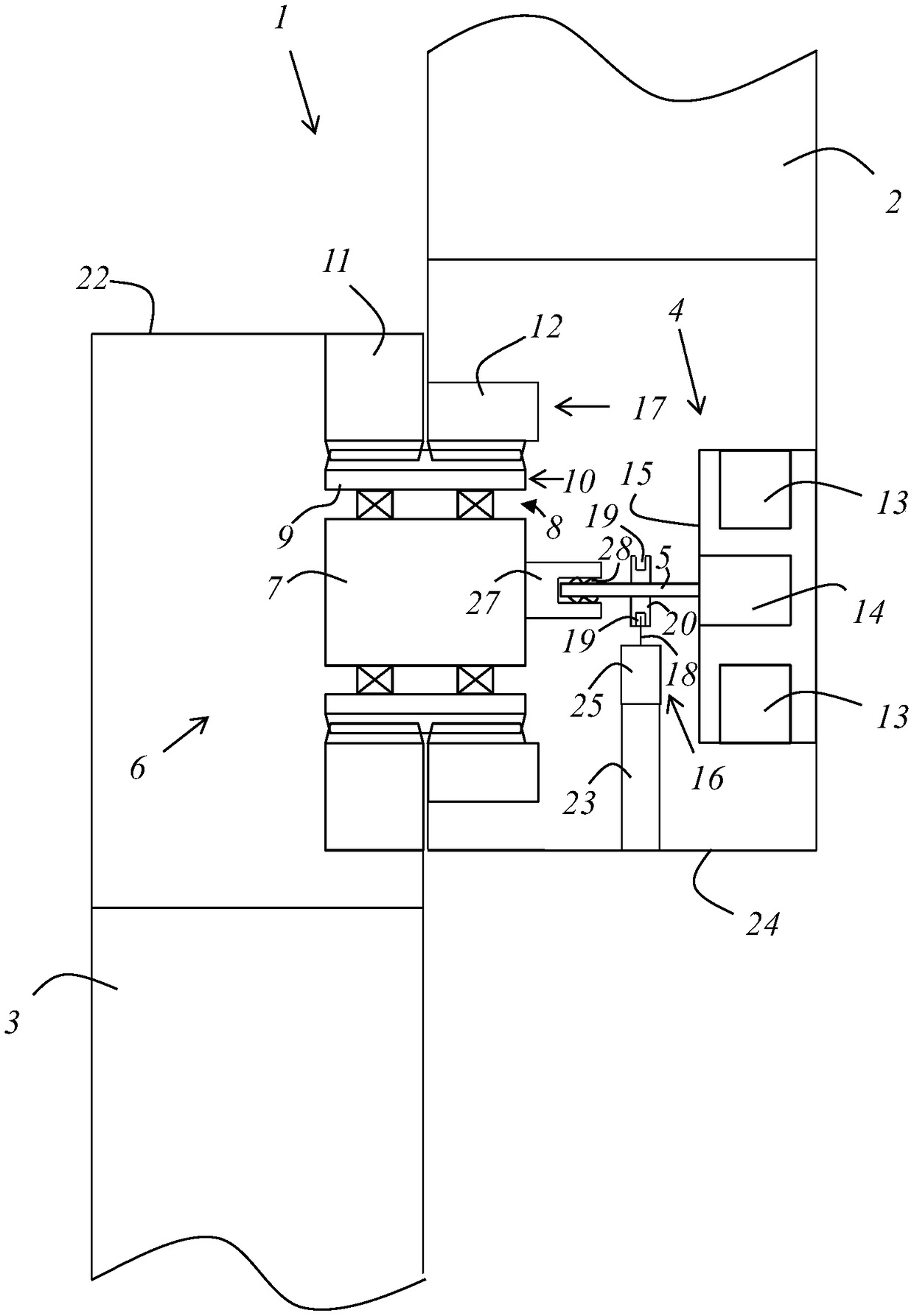

[0031] figure 1 A first exemplary embodiment of a motorized joint 1 for articulated connection of a first support 2 and a second support 3 of a programmable robot is shown. The motorized joint 1 contains a drive motor 4 with a driven shaft 5 and a transmission 6 downstream of the drive motor 4 in terms of transmission. The transmission 6 is designed as a stress wave transmission.

[0032] The motorized joint 1 has a first housing part 24 and a second housing part 22 . The first housing part 24 is rigidly connected to the first carrier 2 , while the second housing part 22 is rigidly connected to the second carrier 3 . Alternatively, it is also possible that the housing of the first support additionally also serves as the first housing part 24 and / or that the housing of the second support additionally also serves as the second housing part 22 .

[0033] In this exemplary embodiment, the drive motor 4 is arranged in the first housing part 24 and the gear mechanism 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com