Cutting blade with different coatings on rear cutter surface

A technology of cutting inserts and flanks, applied in the attachment of tool holders, tools for lathes, turning equipment, etc., can solve the problems of scrap, low cutting insert service life, mismatched cutting edge life, etc., and achieve extended use. Longevity, improved cost performance, performance optimization and matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

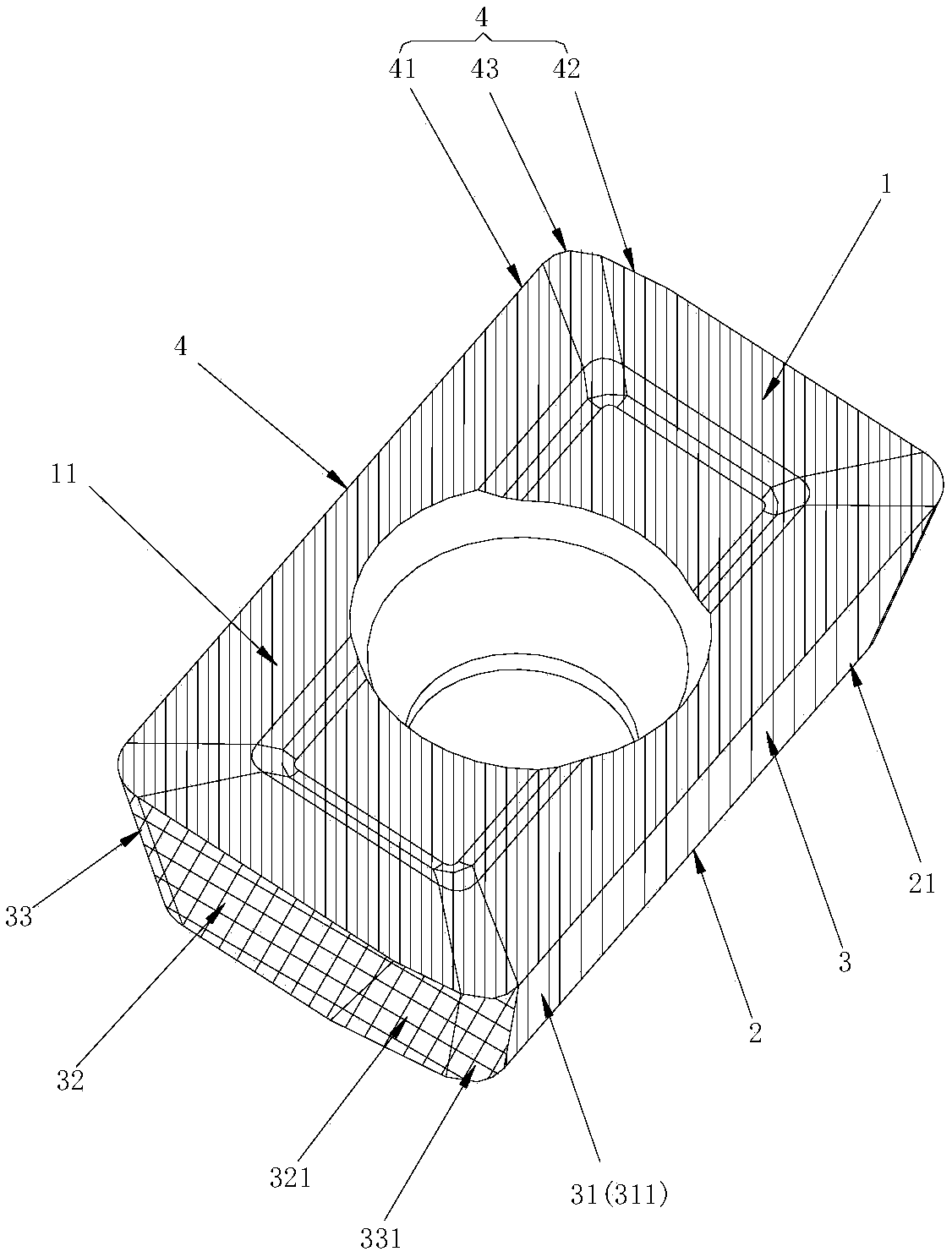

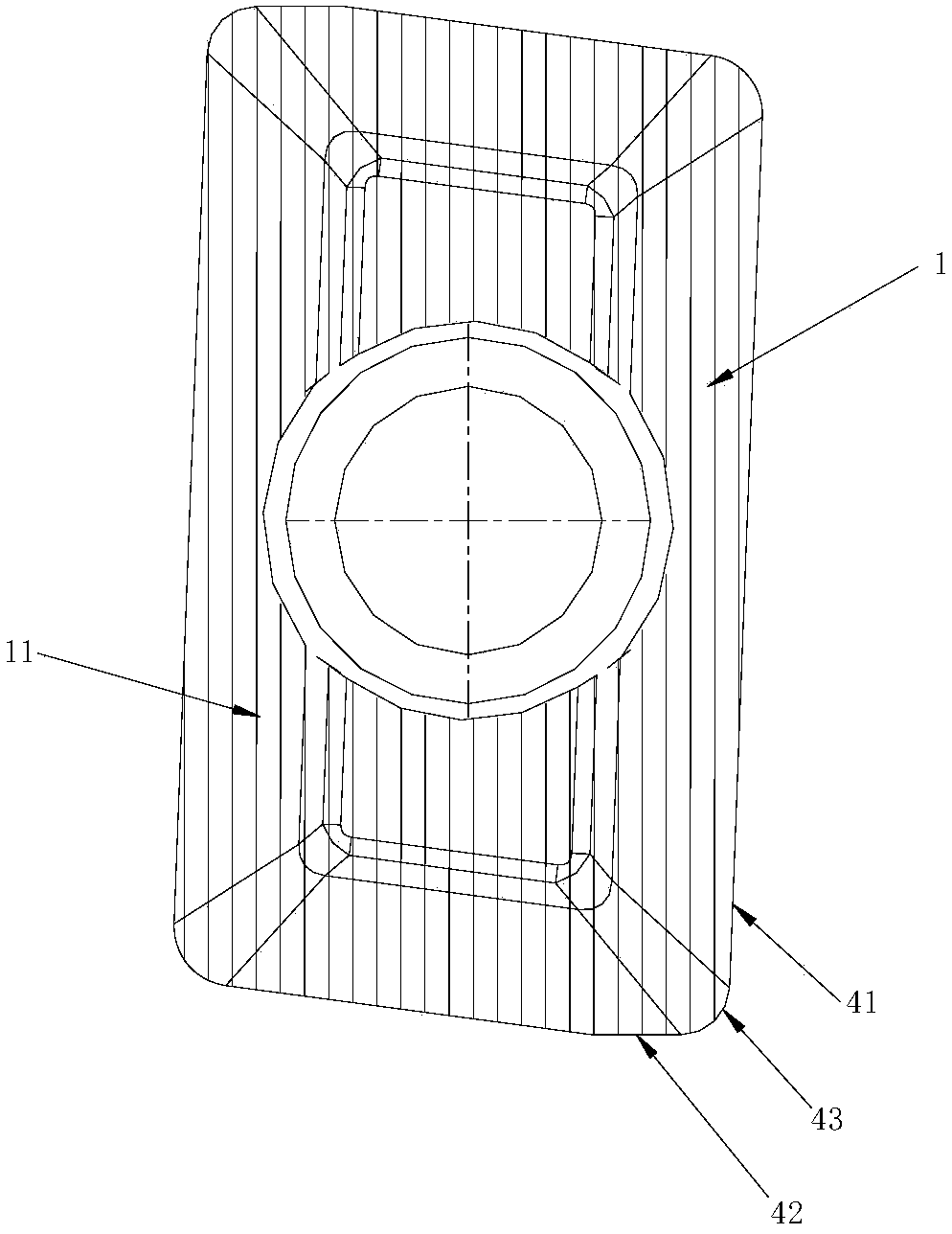

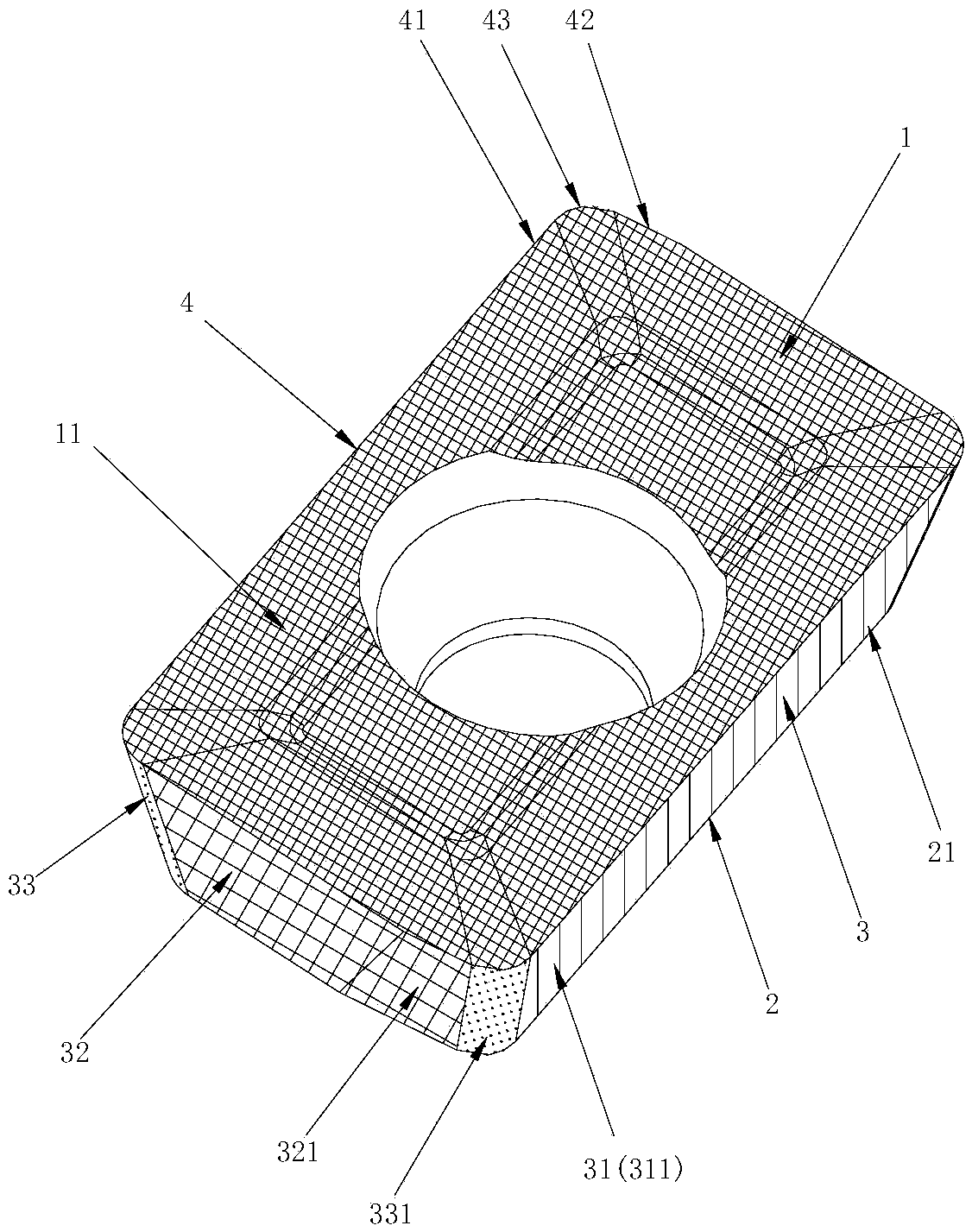

[0031] figure 1 and figure 2 The first embodiment of the cutting insert with different coatings on the flank of the present invention is shown. The cutting insert of this embodiment is surrounded by an upper surface 1, a lower surface 2 and a side surface 3 connecting the upper surface 1 and the lower surface 2, The intersection of the side surface 3 and the upper surface 1 forms more than one set of cutting edge units 4. The cutting edge unit 4 includes adjacent major cutting edges 41, minor cutting edges 42, and corner cutting edges between the major cutting edges 41 and the minor cutting edges 42. Edge 43, side 3 comprises respectively more than a group of primary flanks 31, secondary flanks 32 and angular flanks 33 corresponding to major cutting edges 41, secondary cutting edges 42, and angle cutting edges 43, the primary flanks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com