Synthetic method of benzanilide

A technology of phenylbenzamide and synthesis method, which is applied in the field of N-phenylbenzamide synthesis, can solve the problems of difficult reaction control, complicated reaction, complicated operation, etc., and achieves thorough reaction, few reaction by-products, and high conversion rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

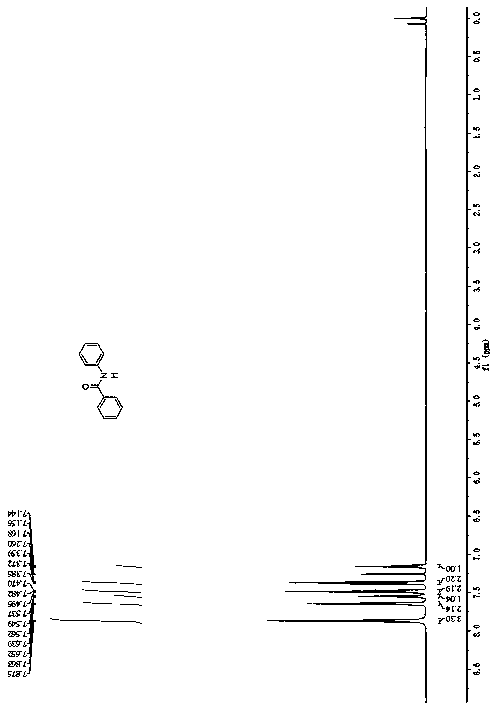

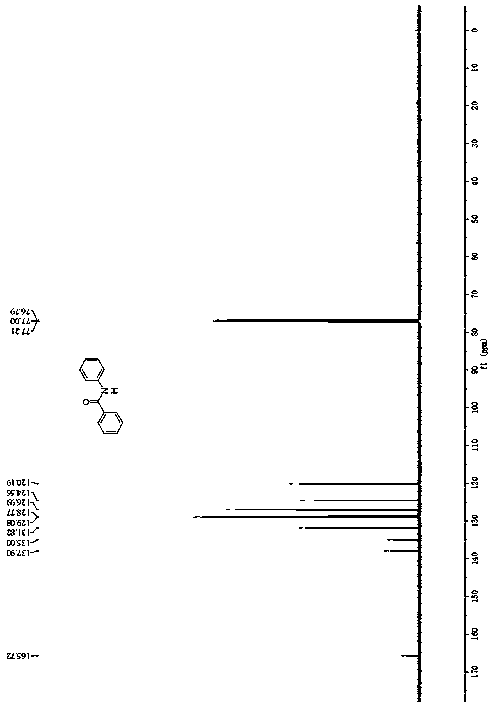

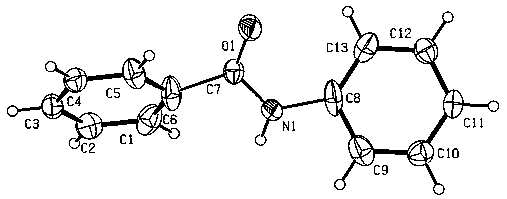

Image

Examples

Embodiment 1

[0038] Example 1 A method for synthesizing N-phenylbenzamide, the method refers to dissolving the substrate α, N-diphenylnitrone and TBAF in a solvent, then adding alkali therein, and stirring and reacting at room temperature for 3 hours Finally, add water to quench the reaction to obtain a mixture; the mixture is extracted 3 times with ethyl acetate, the organic phases are combined, the organic phases are dried and concentrated under reduced pressure, and subjected to petroleum ether-ethyl acetate column chromatography to obtain a white solid N-phenylbenzamide, 57% yield.

[0039] Wherein: solvent refers to acetonitrile. The base refers to potassium hydroxide.

[0040] The mass volume ratio (g / mL) of α, N-diphenylnitrone to solvent is 1:140.

[0041] The mass ratio (g / g) of α, N-diphenylnitrone, TBAF, and base is 1:0.5:0.1.

[0042] The volume ratio (mL / mL) of petroleum ether to ethyl acetate in petroleum ether-ethyl acetate column chromatography is 10:1.

[0043] The con...

Embodiment 2

[0044] Example 2 A method for synthesizing N-phenylbenzamide, the method refers to dissolving the substrate α, N-diphenylnitrone and TBAF in a solvent, then adding alkali to it, and stirring and reacting at room temperature for 3 hours Finally, add water to quench the reaction to obtain a mixture; the mixture is extracted 3 times with ethyl acetate, the organic phases are combined, the organic phases are dried and concentrated under reduced pressure, and subjected to petroleum ether-ethyl acetate column chromatography to obtain a white solid N-phenylbenzamide, yield 62%.

[0045] Wherein: solvent refers to acetonitrile. The base refers to potassium hydroxide.

[0046] The mass volume ratio (g / mL) of α, N-diphenylnitrone to solvent is 1:140.

[0047] The mass ratio (g / g) of α, N-diphenylnitrone, TBAF, and base is 1:1:0.1.

[0048] Petroleum ether-ethyl acetate column chromatography is the same as in Example 1.

[0049] The conditions for concentrating under reduced pressure...

Embodiment 3

[0050] Example 3 A method for synthesizing N-phenylbenzamide, the method refers to dissolving the substrate α, N-diphenylnitrone and TBAF in a solvent, then adding alkali to it, and stirring and reacting at room temperature for 3 hours Finally, add water to quench the reaction to obtain a mixture; the mixture is extracted 3 times with ethyl acetate, the organic phases are combined, the organic phases are dried and concentrated under reduced pressure, and subjected to petroleum ether-ethyl acetate column chromatography to obtain a white solid N-phenylbenzamide, 65% yield.

[0051] Wherein: solvent refers to acetonitrile. The base refers to potassium hydroxide.

[0052] The mass volume ratio (g / mL) of α, N-diphenylnitrone to solvent is 1:140.

[0053] The mass ratio (g / g) of α, N-diphenylnitrone, TBAF, and base is 1:1.2:0.1.

[0054] Petroleum ether-ethyl acetate column chromatography is the same as in Example 1.

[0055] The conditions for concentrating under reduced pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com