A kind of wrought magnesium alloy with high aluminum and high strontium content and preparation method thereof

A technology for deforming magnesium alloy and strontium content, which is applied in the field of magnesium alloy materials, can solve the problems of increasing alloy density, increasing alloy cost, and limiting alloy application, etc., and achieves the effects of reducing grain size, good mechanical properties, and promoting recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

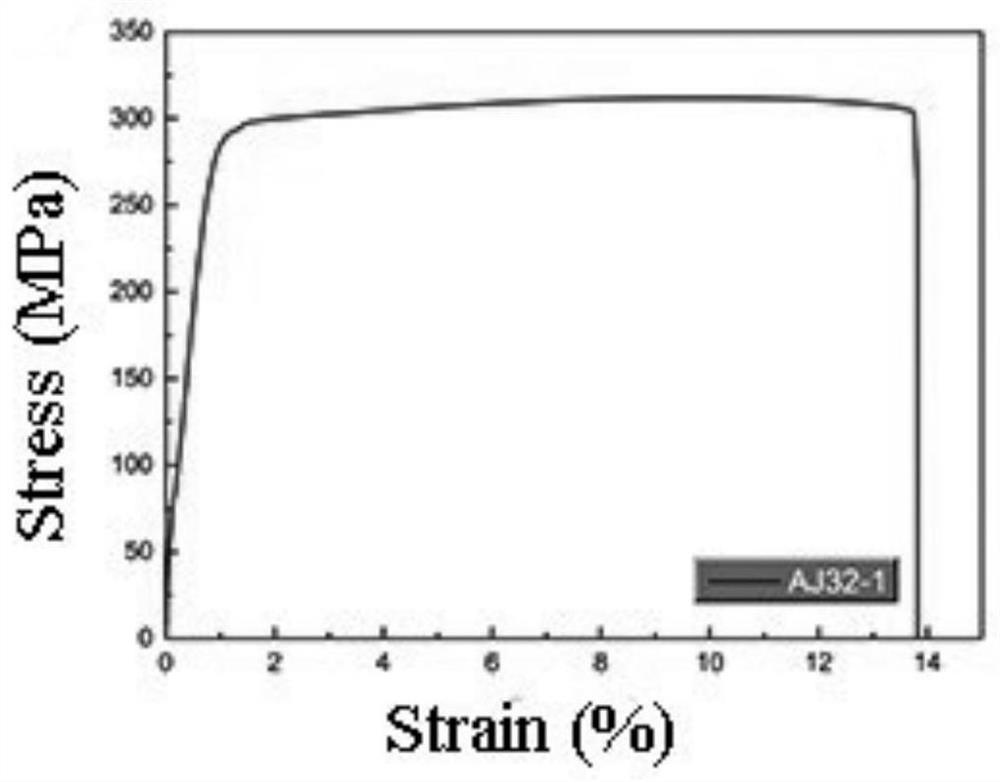

[0023] The wrought magnesium alloy Mg-3Al-2Sr (AJ32) with high aluminum and high strontium content has the following components by mass percentage: 3wt.% Al; 2wt.% Sr; the balance is Mg.

[0024] The preparation method of the deformed magnesium alloy with high aluminum and high strontium content of the present embodiment is as follows:

[0025] (1) The following components are weighed according to mass percentage: 3wt.% aluminum; 2wt.% strontium, the balance being magnesium; strontium is a magnesium-strontium master alloy with a strontium content of 20wt.%, and the metal purity is above 99%;

[0026] (2) Ingot smelting: under the protection of high-purity argon, heat commercially pure magnesium to 740°C, after it melts, add alloying elements aluminum and strontium, stir for 3 minutes, control the solution temperature at 700°C and let stand After 10 minutes, the scum on the surface was removed, and the solution was cast into a mold preheated to 200°C at a temperature of 700°C t...

Embodiment 2

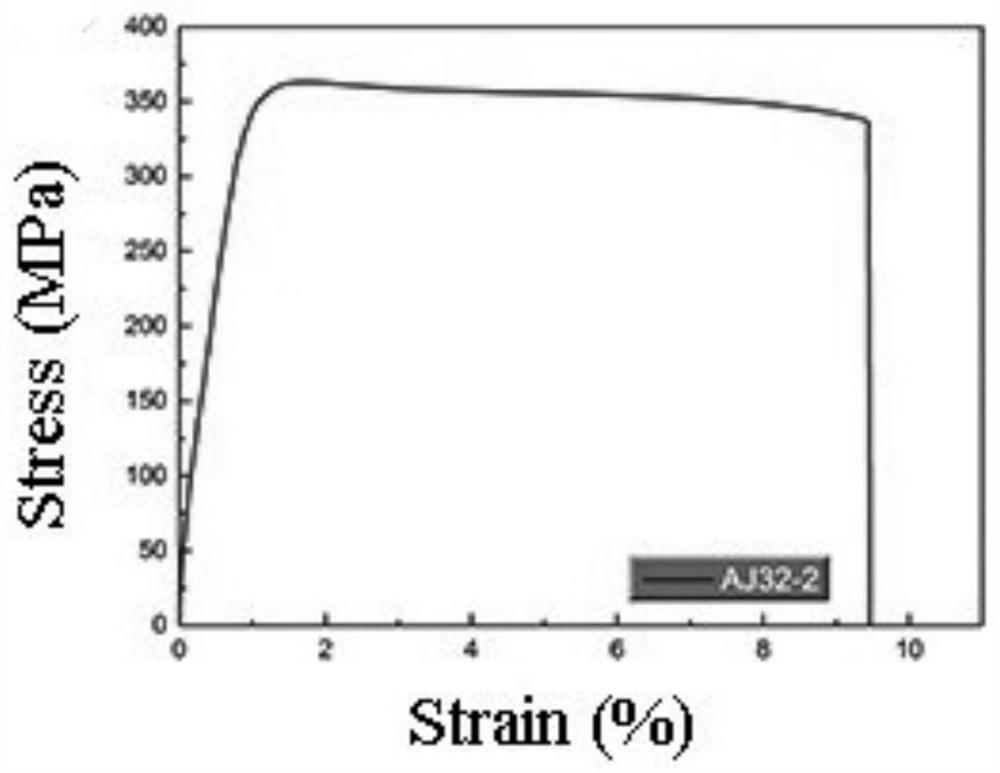

[0031] The wrought magnesium alloy Mg-3Al-2Sr (AJ32) with high aluminum and high strontium content has the following components by mass percentage: 3wt.% Al; 2wt.% Sr; the balance is Mg.

[0032] The preparation method of the deformed magnesium alloy with high aluminum and high strontium content of the present embodiment is as follows:

[0033] (1) The following components are weighed according to mass percentage: 3wt.% aluminum; 2wt.% strontium, the balance being magnesium; strontium is a magnesium-strontium master alloy with a strontium content of 20wt.%, and the metal purity is above 99%;

[0034] (2) Ingot smelting: under the protection of high-purity argon, heat commercially pure magnesium to 740°C, after it melts, add alloying elements aluminum and strontium, stir for 3 minutes, control the solution temperature at 700°C and let stand After 10 minutes, the scum on the surface was removed, and the solution was cast into a mold preheated to 200°C at a temperature of 700°C t...

Embodiment 3

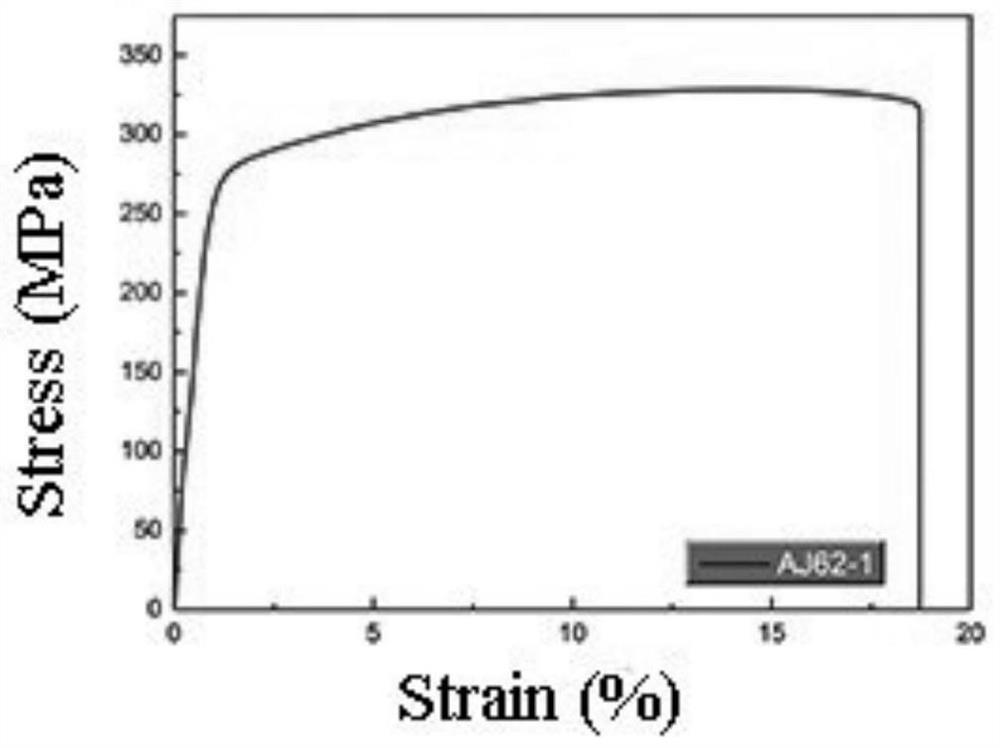

[0039] The wrought magnesium alloy Mg-6Al-2Sr (AJ62) with high aluminum and high strontium content has the following components by mass percentage: 6wt.% Al; 2wt.% Sr; the balance is Mg.

[0040] (1) The following components are weighed according to mass percentage: 6wt.% aluminum; 2wt.% strontium, and the balance is magnesium; strontium is a magnesium-strontium master alloy with a strontium content of 20wt.%, and the metal purity is above 99%;

[0041] (2) Ingot smelting: under the protection of high-purity argon, heat commercially pure magnesium to 740°C, after it melts, add alloying elements aluminum and strontium, stir for 3 minutes, control the solution temperature at 700°C and let stand After 10 minutes, the scum on the surface was removed, and the solution was cast into a mold preheated to 200°C at a temperature of 700°C to obtain a deformed magnesium alloy ingot with high aluminum and strontium content;

[0042] (3) Homogenization treatment: the ingot of strontium-contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com