Method for improving processing property of FeCrNiAl-based high-entropy alloy

A high-entropy alloy and processing performance technology, applied in the field of metals and alloys, to achieve the effects of eliminating forging stress, reducing deformation dislocations, and improving plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

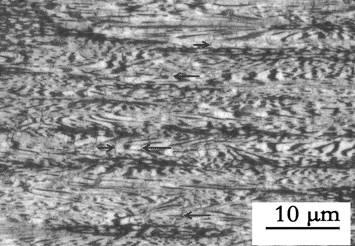

[0030] The as-cast high-entropy alloy is optimized for machinability. Its nominal chemical composition (at.%) is: 23Fe, 23Cr, 23Ni, 23Al, 8Cu. The as-cast metallographic photo is as follows figure 1 As shown, the average grain size is 30 μm.

[0031] In the first step, keep warm at 1250°C for 12 hours, and then cool to room temperature with water.

[0032] In the second step, at 1200°C, take it out after holding for 3 hours, and then start forging deformation at 1180°C, the final forging temperature is 1050°C, and the forging ratio is 1:6; then air cool to room temperature.

[0033] The third step is to perform periodic annealing treatment on the forged sample. The annealing temperature is 1160°C. After two cycles of annealing, it is air-cooled to room temperature.

[0034]The fourth step is to perform compression deformation on the above-mentioned processed sample (performed on the Gleeble thermal-mechanical simulation testing machine), the deformation temperature ranges fro...

Embodiment 2

[0036] Using the methods (1) to (4) above, the sample was kept at 1200°C for 18 hours, and then water-cooled to room temperature. And keep it warm at 1225°C for 1.5h before forging, and immediately carry out high-temperature forging. The initial forging temperature was 1200°C, the final forging temperature was 1060°C, and the forging ratio was 1:8, followed by three cycles of annealing at 1120°C. After 15% cold deformation at room temperature, observe the microstructure of the deformed alloy and analyze its rheological behavior. The results are as follows Figure 5 shown. Even after deformation at room temperature, no microcracks were observed in the microstructure, and the deformed macroscopic specimens remained intact.

Embodiment 3

[0038] An optimization process for optimizing machinability of a high-entropy alloy of another composition according to the method described above. The nominal chemical composition of the implemented alloy is: 23Fe-23Cr-23Ni-23Al-8Mo (at.%), and the sample is kept at 1280°C for 8 hours to fully homogenize and then cooled to room temperature. Free forging is carried out after holding at 1250°C for 2 hours. The initial forging temperature is 1160°C, the final forging temperature is 1030°C, and the forging ratio is 1:7. This was followed by 2 cycles of high temperature annealing at 1150 °C. Then it was compressed and deformed at 800°C, the deformation amount was 50%, and its structure was observed. The results are as follows: Figure 6 shown.

[0039] Implementation Effect

[0040] The inventors carried out thermal compression deformation with different parameters on the as-cast and treated high-entropy alloys, analyzed and simulated their rheological behavior to obtain their...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com