Pure water hydrogen production and direct liquid hydrogen storage and hydrogenation integral device and control method

A liquid hydrogen storage, direct technology, applied in the direction of cells, electrolysis components, electrolysis process, etc., can solve the problems of slow hydrogen storage and low storage efficiency, and achieve the effect of high hydrogen storage efficiency, safe and convenient transportation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

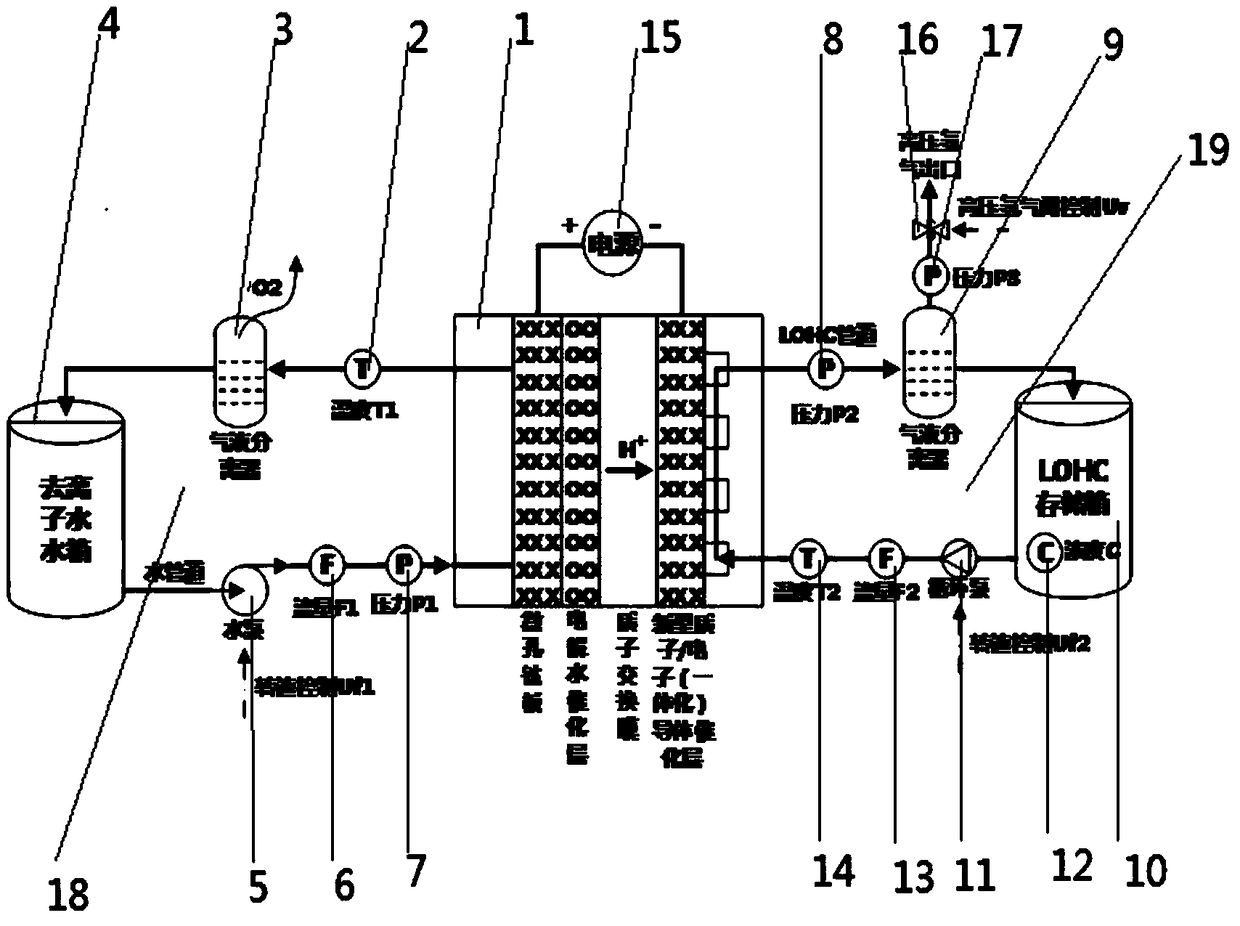

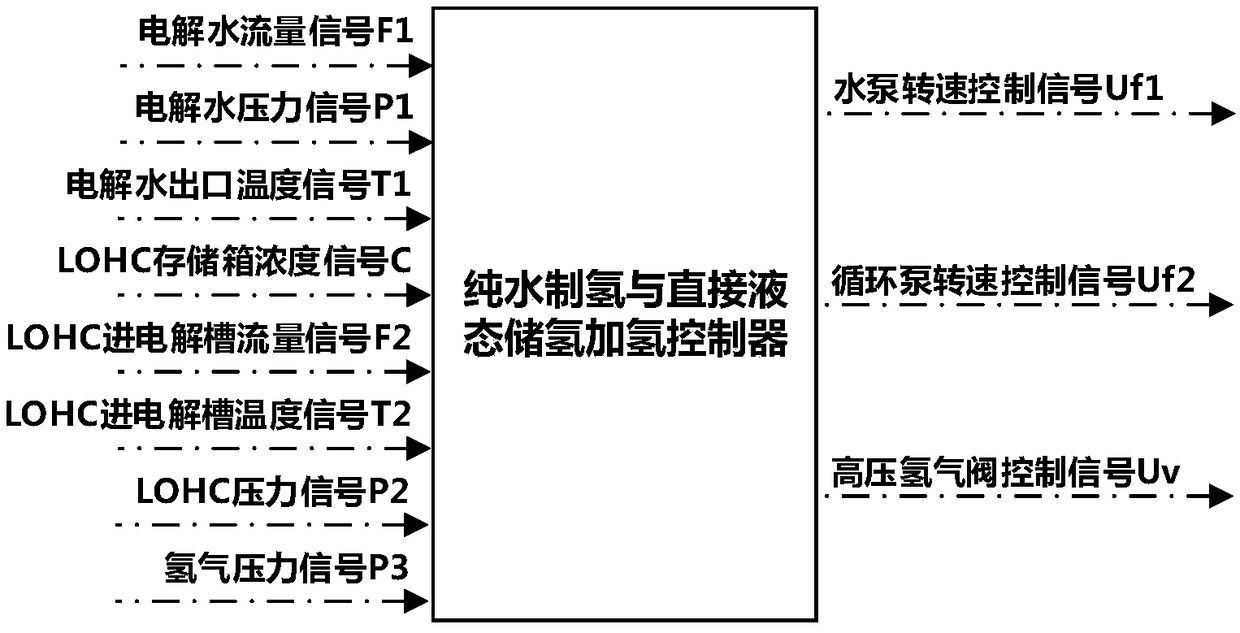

[0024] The integrated device and control method of pure water hydrogen production and direct liquid hydrogen storage and hydrogenation of the present invention, such as figure 1 As shown, it includes a direct hydrogenation electrolyzer 1 connected to a power supply 15, a deionization circulation system 18 and a liquid organic hydrogen storage material circulation system 19; the anode side of the direct hydrogenation electrolyzer 1 is provided with deionized water, and the cathode side is provided with liquid Organic hydrogen storage material, direct hydrogenation electrolytic cell 1 is provided with microporous titanium plate, electrolytic water catalytic layer, proton exchange membrane and new proton / electron conductor catalytic layer in sequence from anode to cathode; microporous titanium plate and deionization circulation system 18 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com