Automatic recognition and counting machine for wrong mixed materials and its realization method

An automatic identification and counting machine technology, applied in the field of automation, can solve the problems of high labor intensity, high repeatability of detection process, high labor cost, etc., and achieve the effect of flexible operation, fast speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

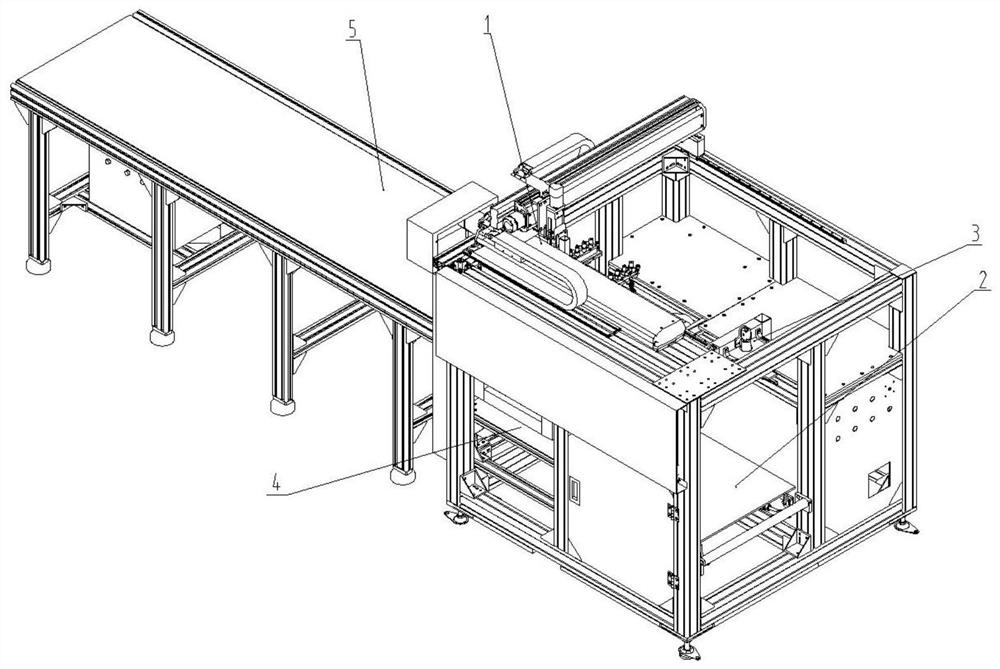

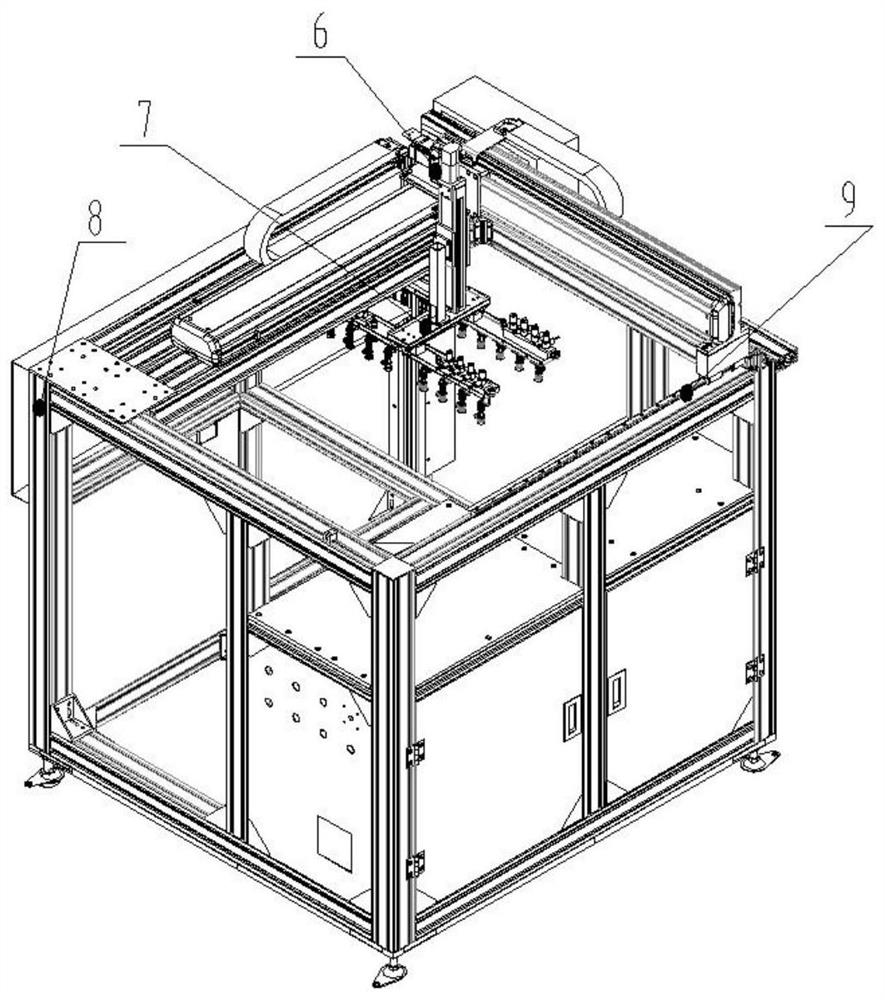

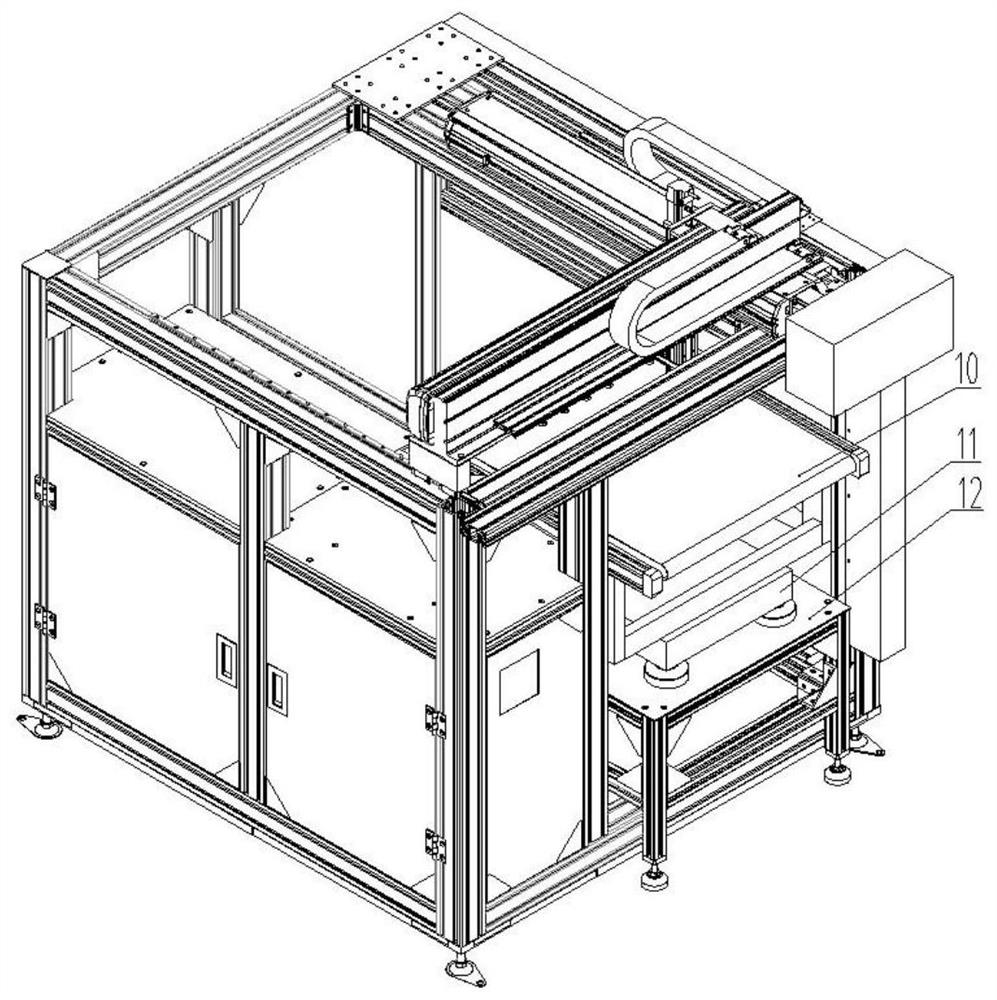

[0034] Such as Figure 1 to Figure 7 As shown, the automatic identification and counting machine for mixed materials is composed of five parts: PCB handling robot, visual inspection component, weighing component, lifting component, and transmission component.

[0035] The PCB handling robot can be divided into rack 8, linear module mobile platform 6, suction cup gripper 7, linear slide rail 9 and other components. The frame 8 is made of aluminum alloy, and the inside is hollow, and various components can be installed. The linear module mobile platform 6 is composed of three linear modules in an XYZ three-coordinate format. One end of the linear module mobile platform 6 is fixed on the frame 8 , and the other end is fixed on the frame 8 through a linear slide rail 9 . The suction cup gripper 7 is composed of parts such as a vacuum generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com