Cold experiment method of solidification process

An experimental method and cold state technology, applied in the field of continuous casting of iron and steel, can solve the problems of complex molten steel solidification simulation device, inability to observe molten steel crystallization and segregation behavior, etc., to improve heating effect or cooling effect, improve cooling effect, improve Effects of analog effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

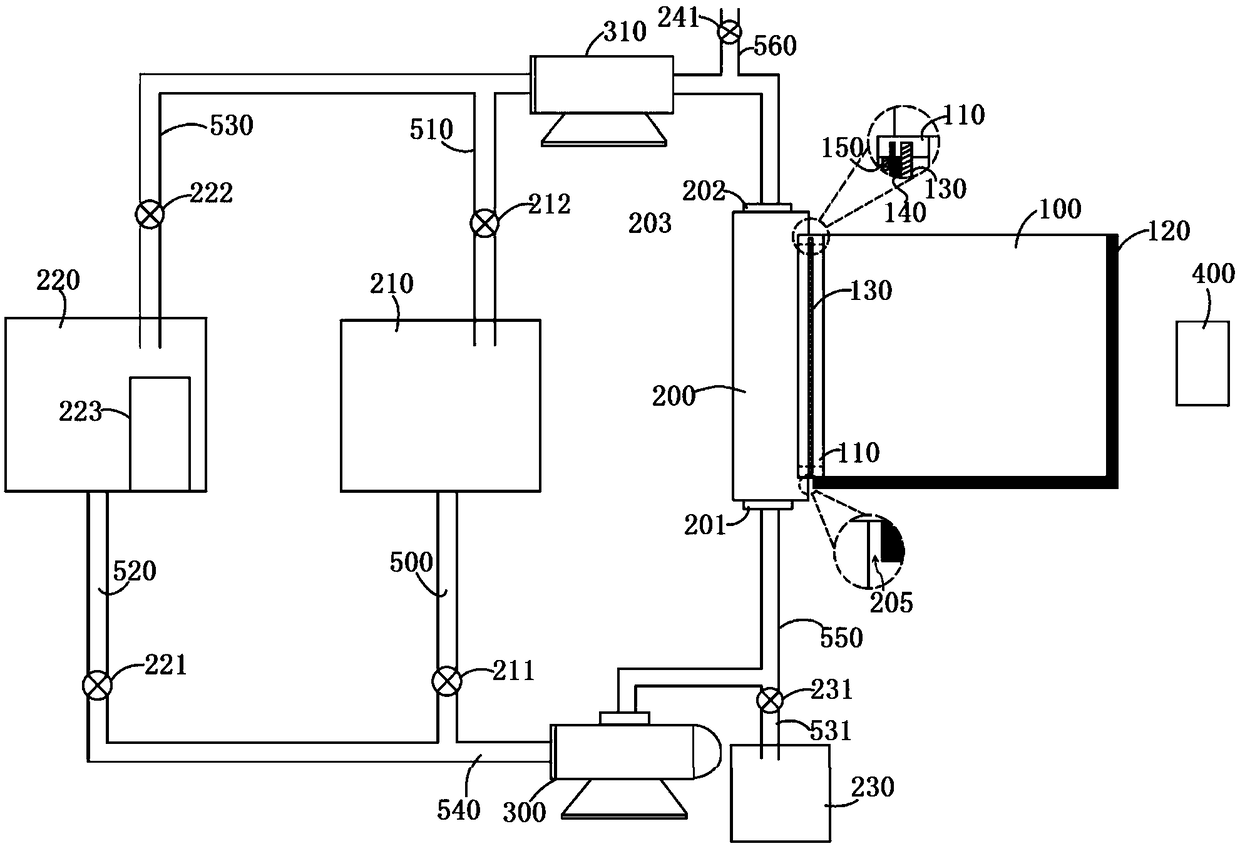

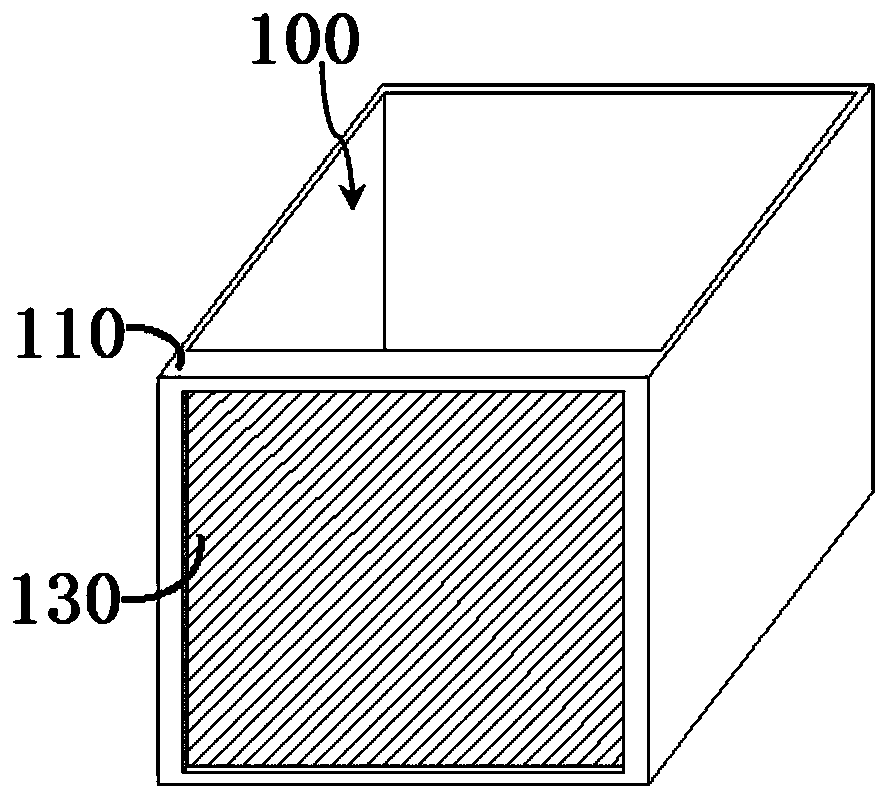

[0042] In the method of simulating the solidification process of molten steel in this embodiment, the hot water in the hot water tank 210 enters the heat exchange pool 200 through the pipeline, and the hot water in the heat exchange pool 200 heats the metal plate 130; the transparent heating film 120 heats and insulates the side wall and bottom of the test pool 100; then pours the test solution into the test pool 100, and after the hot water in the heat exchange pool 200 is discharged, the cold water in the cold water tank 220 enters the The heat exchange pool 200, the cold water in the heat exchange pool 200 cools the metal plate 130, the experimental solution crystallizes on the surface of the metal plate 130, and crystallizes inside the experimental solution, and the crystallization process is observed with the observer 400. combine Figure 5 As shown, the specific steps are:

[0043] Step 1: Heat and keep warm

[0044] The transparent heating film 120 installed on the outs...

Embodiment 2

[0060] The basic content of this embodiment is the same as that of Embodiment 1, except that the water outlet 202 is connected to the water inlet end of the second water pump 310 through a pipeline, and the water outlet end of the second water pump 310 is connected to the hot water inlet pipe 510 through a pipeline. The hot water pipe 510 is located on the top of the hot water tank 210, so that the water outlet 202 is indirectly connected to the hot water tank 210, and the hot water used in the preheating process can be circulated into the hot water tank 210 through the hot water inlet pipe 510. The hot water is recycled, which greatly saves hot water resources; and the hot water inlet pipe 510 is provided with a hot water inlet valve 212 for controlling the recovery and treatment of hot water; the outlet end of the second water pump 310 passes through the pipe and The cold water inlet pipe 530 is connected, and the cold water inlet pipe 530 is located at the upper part of the ...

Embodiment 3

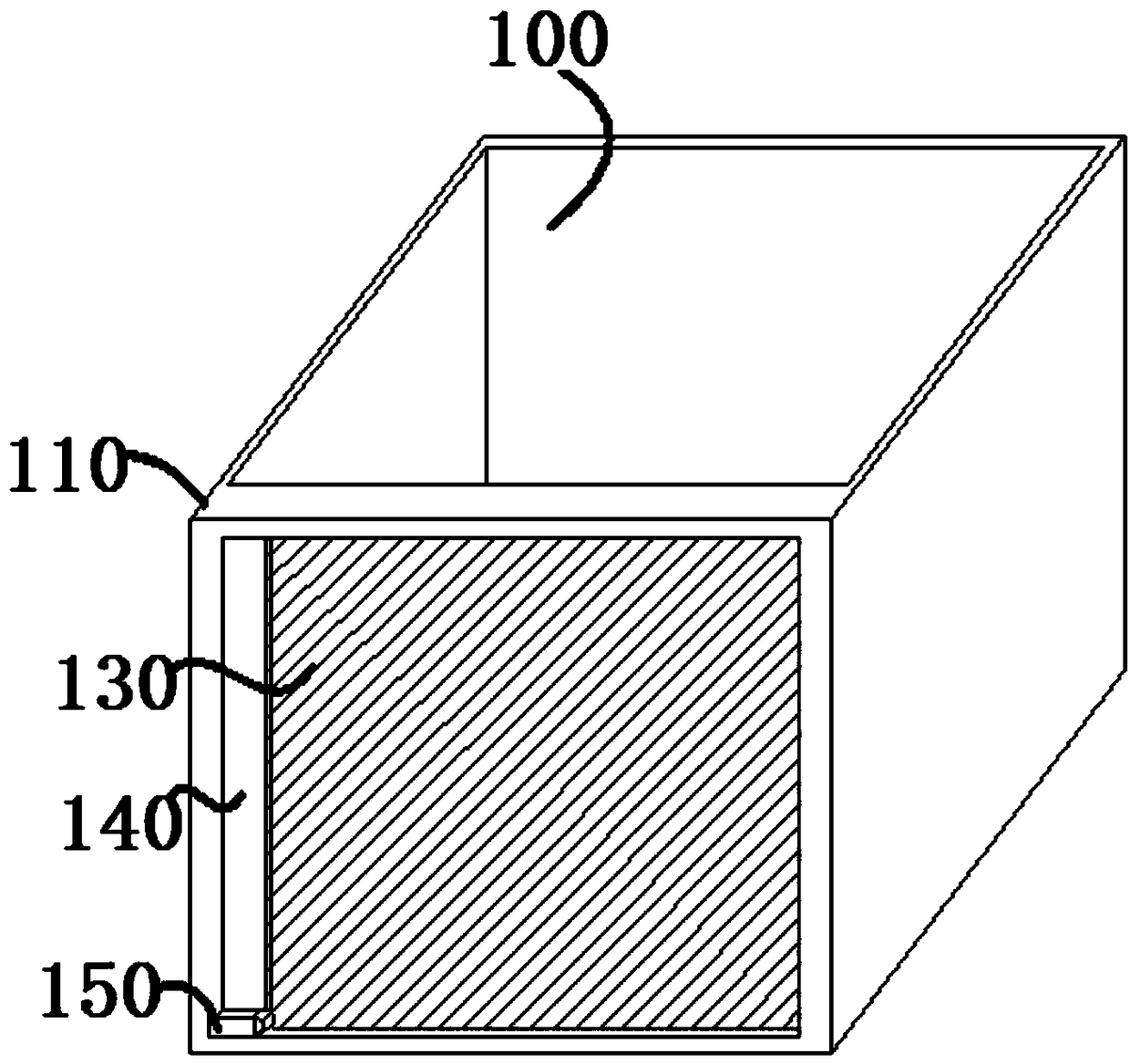

[0062] combine image 3As shown, the basic content of this embodiment is the same as that of Embodiment 1, except that the first water pump 300 will generate air bubbles during pumping, and the air bubbles will adhere to the surface of the metal plate 130 . One end of the test pool 100 is provided with a slide rail, the slide rail is located at the bottom of the metal plate 130, the bubble brush 140 is slidably installed on the slide rail, the bubble brush 140 is provided with a servo motor 150, and the servo motor 150 is used to drive the bubble brush 140. Slide back and forth along the length of the slide rail; the side of the bubble brush 140 with the brush plate is in contact with the surface of the metal plate 130, and the bubble brush 140 can erase the bubbles attached to the surface of the metal plate 130 during the reciprocating motion , so that the attached air bubbles are separated from the surface of the metal plate 130, and the separated air bubbles are discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com