CIM-based modeling method for optical fiber preform production process

An optical fiber preform and production process technology, which is applied in the field of information entity modeling in the production process of optical fiber preform based on CIM, can solve problems such as the difficulty of using and processing data in an intelligent manufacturing system, and achieve improved efficiency and quality. Effects of operations and information interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

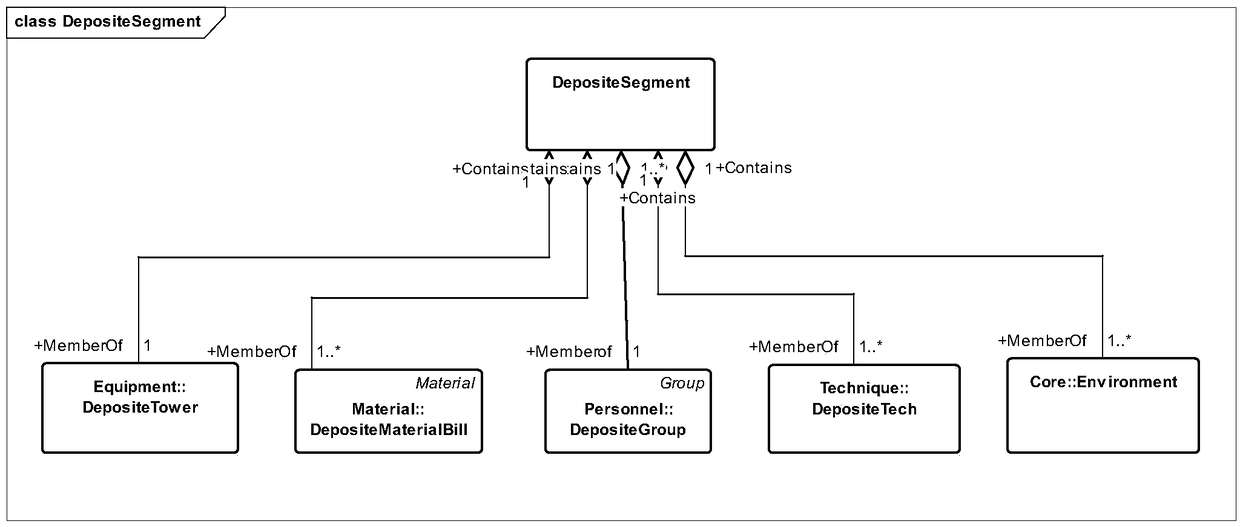

[0070] Aiming at the production process of optical fiber preform in VAD process, the present invention can define specific CIM categories of personnel, equipment and materials in step 2 on the basis of step 1.

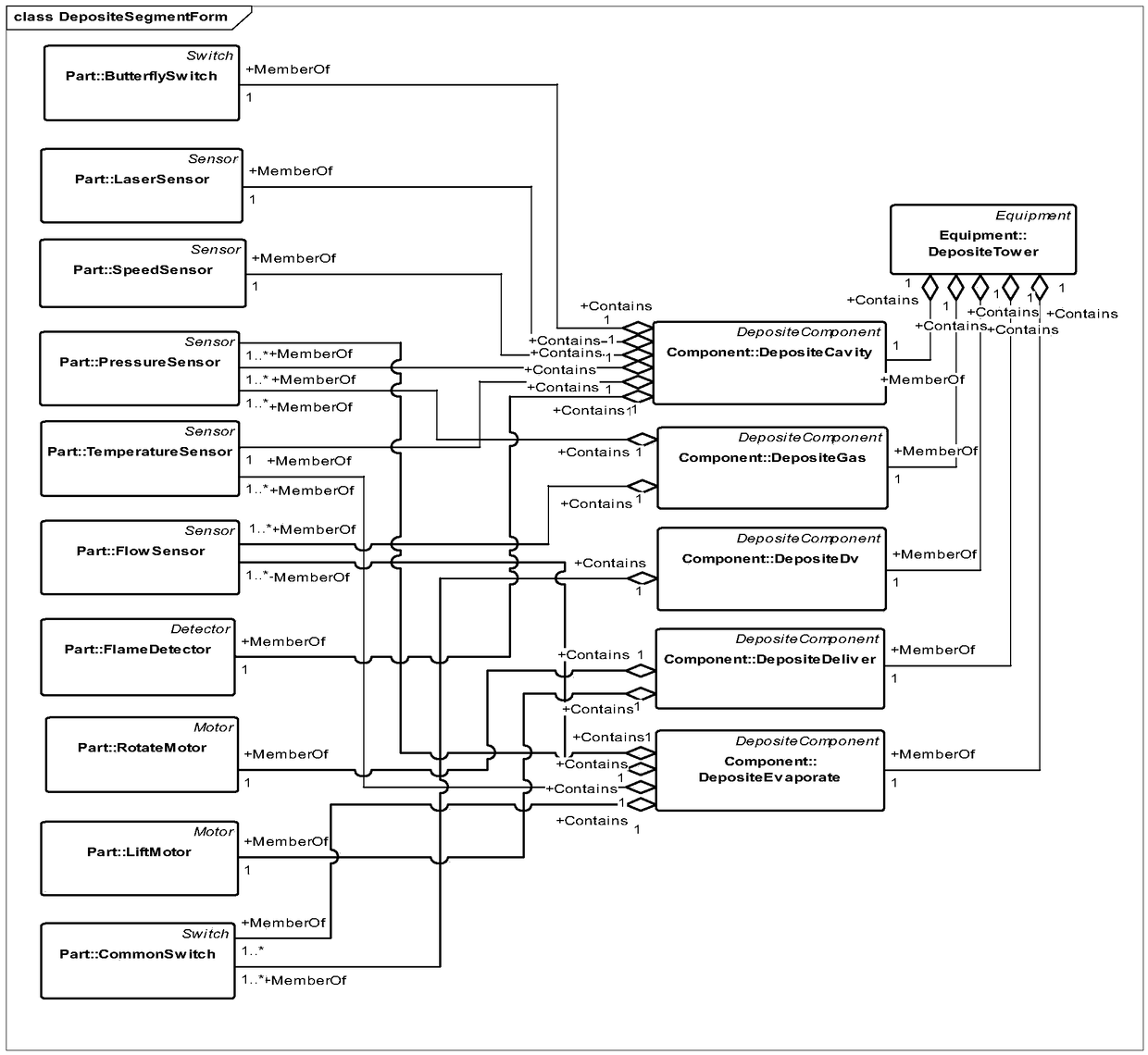

[0071] Such as figure 2Shown is the result of modeling the deposition tower equipment in the VAD process according to step 2 of the present invention. The CIM class DepositTower is derived from the equipment (Equipement) CIM base class, which represents the deposition tower; this class aggregates the CIM classes DepositeCavity, DepositGas, DepositDV, DepositDeliver and DepositEvaporate, which are all derived from the component (Component) CIM base class , indicating that the deposition tower equipment is composed of several components such as cavity system, gas circuit system, valve system, transmission system, and evaporation system; each specific component class aggregates several parts classes, such as the CIM class DepositCavity aggregates parts (Part ) Several d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com