Preparation of Magnetic Functional Materials

A magnetic function and raw material technology, applied in the field of preparation of magnetic functional materials, can solve the problems of low performance, achieve the effect of strengthening soft magnetism, reducing domain wall displacement, and promoting uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a kind of preparation method of magnetic function material, and described preparation method comprises:

[0018] (1) Preparation of material A: mix C, Nd, Cd, Mn, S and Fe, mix and smelt it to obtain alloy liquid, and atomize the alloy liquid to obtain material A, wherein S and Fe are Added in the form of sulfur-iron alloy;

[0019] (2) Preparation of material B: Fe, Cd, Nd, Si, Sb and Sn are mixed into ingredients, mixed and smelted to obtain alloy liquid, and alloy liquid is atomized to obtain material B;

[0020] (3) Preparation of material C: PbO 2 、Al 2 o 3 , CaO, CdO, K 2 O and SiO 2 Mixing ingredients, then crushing, drying, sieving and sintering to obtain material C;

[0021] (4) Preparation of material D: PbO 2 , Mn 2 o 3 , CdO, Nd 2 o 3 and Fe 2 o 3 Mixing ingredients, then crushing, drying, sieving and sintering to obtain material D;

[0022] (5) Mix material B and material C 1:1, and compact to form a blank M, and...

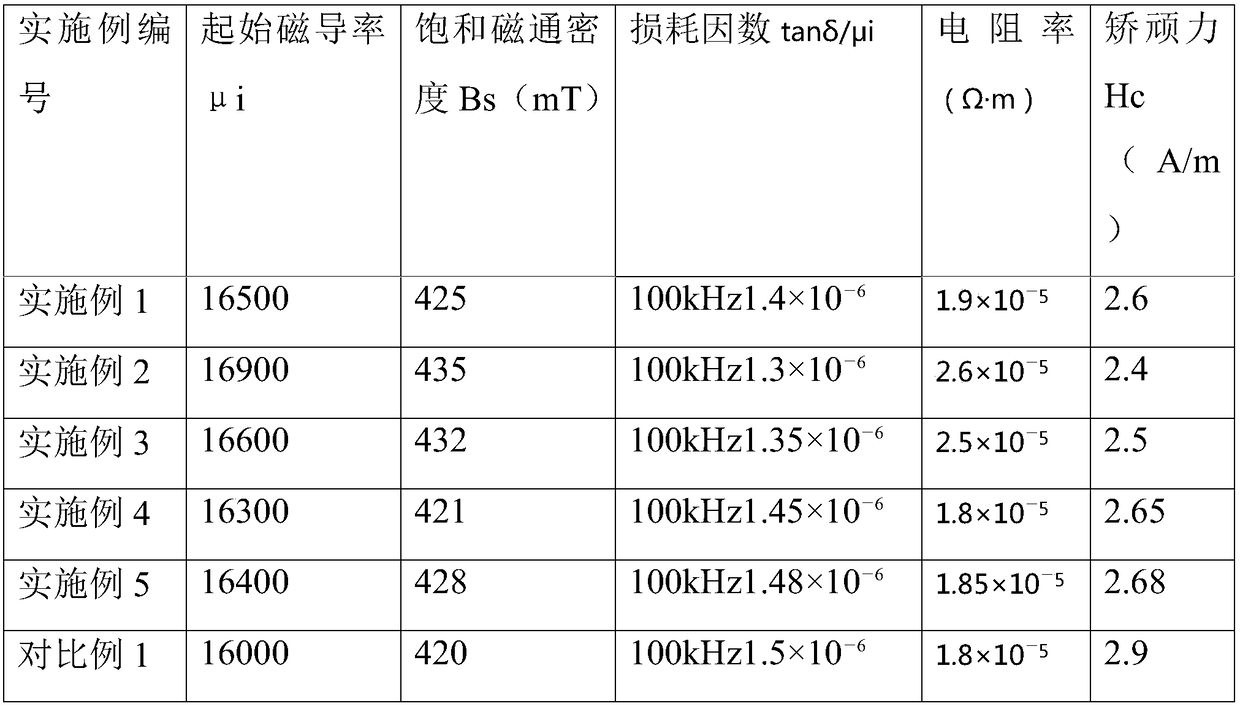

Embodiment 1

[0048] Carry out the preparation of magnetic function material according to above-mentioned method, wherein, material A comprises following raw material composition by weight: C0.28%, Nd 3%, Cd 0.01%, Mn 21%, S 2.3% and balance Fe; Material B comprises following Raw material components in parts by weight: Fe 1%, Cd 0.01%, Nd 3%, Si 0.02%, Sb 11% and balance Sn; material C includes the following raw material components in parts by weight: PbO 2 0.1%, Al 2 o 3 0.1%, CaO 0.1%, CdO 0.1%, K 2 O 8% and balance SiO 2 ; Material D includes the following raw material components in parts by weight: PbO 2 0.1%, Mn 2 o 3 16%, CdO 0.1%, Nd 2 o 3 0.1% and balance Fe 2 o 3 ; The weight ratio of material A, material B, material C and material D is 0.1:0.005:0.005:10; the weight ratio of material B and material C is 1:1.

Embodiment 2

[0050] Carry out the preparation of magnetic function material according to the above-mentioned method, wherein, material A comprises following raw material composition by weight: C0.32%, Nd 4%, Cd 0.04%, Mn 23%, S 2.5% and balance Fe; Material B comprises following Raw material components in parts by weight: Fe 3%, Cd 0.03%, Nd 5%, Si 0.05%, Sb 13% and balance Sn; material C includes the following raw material components in parts by weight: PbO 2 0.2%, Al 2 o 3 0.3%, CaO 0.3%, CdO 0.3%, K 2 O 10% and balance SiO 2 ; Material D includes the following raw material components in parts by weight: PbO 2 0.3%, Mn 2 o 3 17%, CdO 0.3%, Nd 2 o 3 0.3% and balance Fe 2 o 3 ; The weight ratio of material A, material B, material C and material D is 0.3:0.015:0.015:10; the weight ratio of material B and material C is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com