A method for peel off a perovskite oxide piezoelectric thin film on graphene by using a metal stress layer

A perovskite oxide and metal stress technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as complex processes, impacts, and difficulty in satisfying thin films, and achieve the effect of smooth surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Choose SiO interspersed with graphene 2 Barium titanate (BaTiO) grown on a Si substrate 3 , BTO) film;

[0033] 2) Load the sample and the Cr target into the magnetron sputtering film growth chamber;

[0034] 3) Evacuate the air pressure in the vacuum chamber to 5×10 -4 Below Pa, remove the pollutants adsorbed on the surface of the film;

[0035] 4) Pass high-purity argon gas into the vacuum chamber, and control the air pressure at 0.5Pa;

[0036] 5) Turn on the pulse power supply, control the power at 50W, grow for 5 minutes, increase the power to 150W, and grow for 2 hours;

[0037] 6) Turn off the pulse power supply, inject air into the cavity, and take out the sample;

[0038] 7) Adhesive tape is attached to the surface of the sample obtained in step 6), and the tape is torn off the substrate to realize the peeling off of the film.

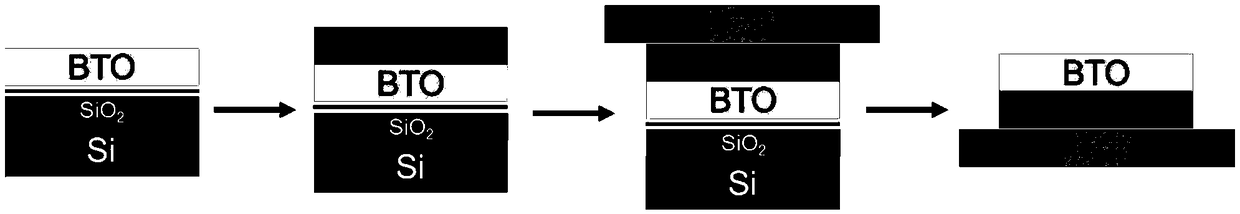

[0039] Such as figure 1 , the stripping process is shown below. Such as figure 2 , the peeled film is observed by SEM, an...

Embodiment 2

[0041] 1) Choose SiO interspersed with graphene 2 Barium titanate (BaTiO) grown on a Si substrate 3 , BTO) film;

[0042] 2) Load the sample and the Cr target into the magnetron sputtering film growth chamber;

[0043] 3) Evacuate the air pressure in the vacuum chamber to 5×10 -4 Below Pa, remove the pollutants adsorbed on the surface of the film;

[0044] 4) Introduce high-purity argon gas into the vacuum chamber, and control the air pressure at 0.3Pa;

[0045] 5) Turn on the pulse power supply, control the power at 40W, grow for 5 minutes, increase the power to 150W, and grow for 2 hours;

[0046] 6) Turn off the pulse power supply, inject air into the cavity, and take out the sample;

[0047] 7) Adhesive tape is attached to the surface of the sample obtained in step 6), and the tape is torn off the substrate to realize the peeling off of the film.

Embodiment 3

[0049] 1) Choose SiO interspersed with graphene 2 Barium titanate (BaTiO) grown on a Si substrate 3 , BTO) film;

[0050] 2) Load the sample and the Cr target into the magnetron sputtering film growth chamber;

[0051] 3) Evacuate the air pressure in the vacuum chamber to 5×10 -4 Below Pa, remove the pollutants adsorbed on the surface of the film;

[0052] 4) Pass high-purity argon gas into the vacuum chamber, and control the air pressure at 1.0Pa;

[0053] 5) Turn on the pulse power supply, control the power at 100W, grow for 10 minutes, increase the power to 200W, and grow for 2 hours;

[0054] 6) Turn off the pulse power supply, inject air into the cavity, and take out the sample;

[0055] 7) Adhesive tape is attached to the surface of the sample obtained in step 6), and the tape is torn off the substrate to realize the peeling off of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com