Shell-core structure degradable stent and preparation method thereof

A technology of nuclear structure and hollow structure, which is applied in the field of medical devices, can solve the problems that a single polymer cannot take into account mechanical properties, degradable properties and processability, etc., so as to reduce the risk of stent fracture, prevent mechanical fracture, and have good degradation properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

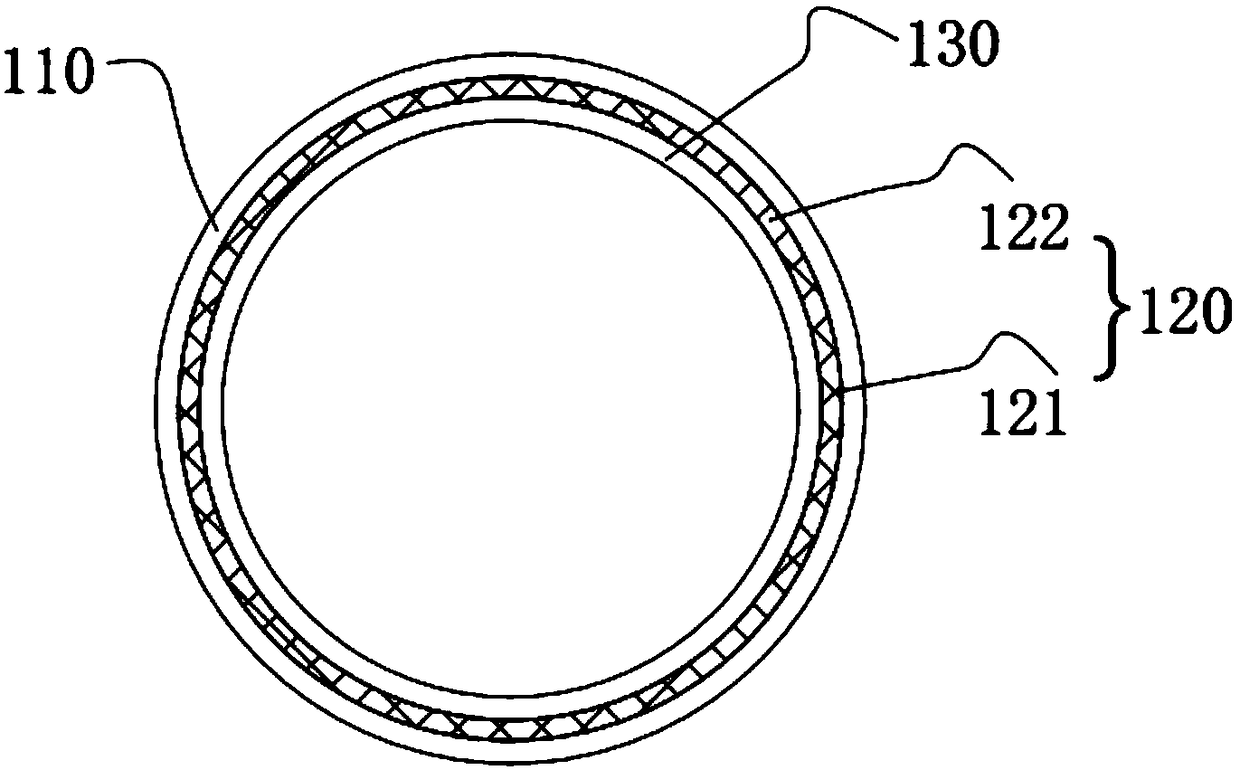

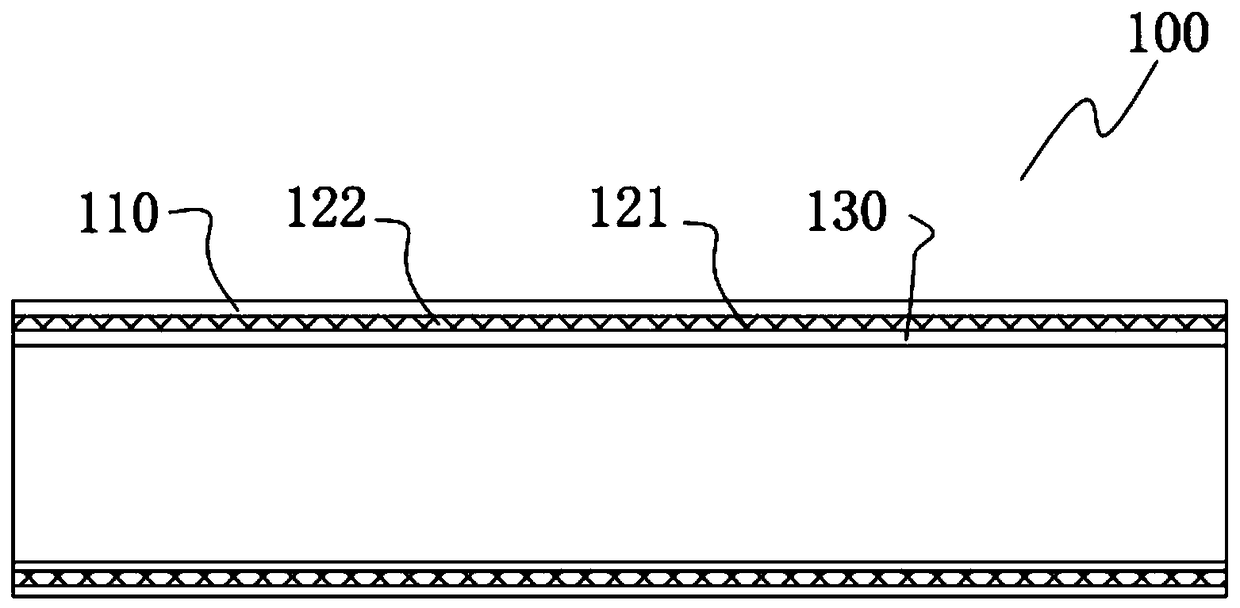

[0063] The invention provides a degradable support with a shell-core structure. The three-layer structure can optimize the mechanical support force in the radial direction to a certain extent, and effectively reduce the breakage of the support during processing or use. The invention also provides a method for preparing a degradable scaffold with a shell-core structure, which greatly reduces the processing difficulty of the scaffold and the risk of scaffold breakage under the condition of ensuring good degradation performance of the degradable scaffold. Compared with the traditional method that can only use a variety of materials, a solution that meets the above requirements at the same time is achieved through appropriate physical processing methods and a unique bracket structure.

[0064] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com