Debridement device for general surgery

A general surgery and main engine technology, applied in the field of debridement devices for general surgery, can solve the problems of cross-infection of patients' affected parts, unfavorable wound recovery of patients, large heat generation, etc., to improve the efficiency of electric/acoustic conversion and improve the conversion of electric/acoustic Efficiency, the effect of changing the mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below.

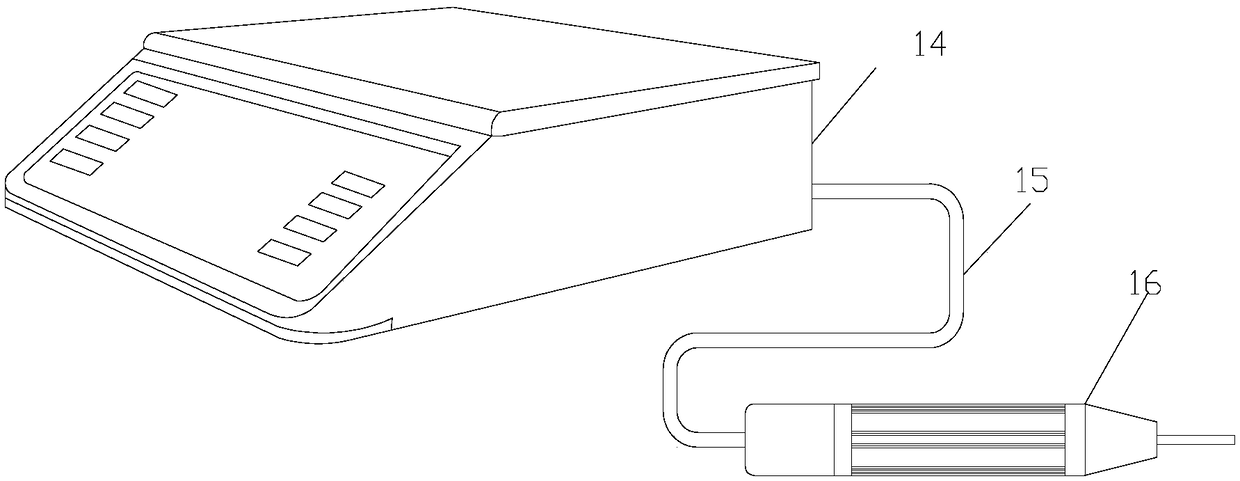

[0019] see figure 1 , the general surgery debridement device of the present embodiment comprises a host 14, a debridement injection head 16 and a connecting pipe 15 connected between the host 14 and the debridement injection head 16, and the host 14 is provided with a The debridement liquid with different components is mixed according to the set ratio, and then pressurized and delivered to the debridement liquid pump of the debridement injection head 16;

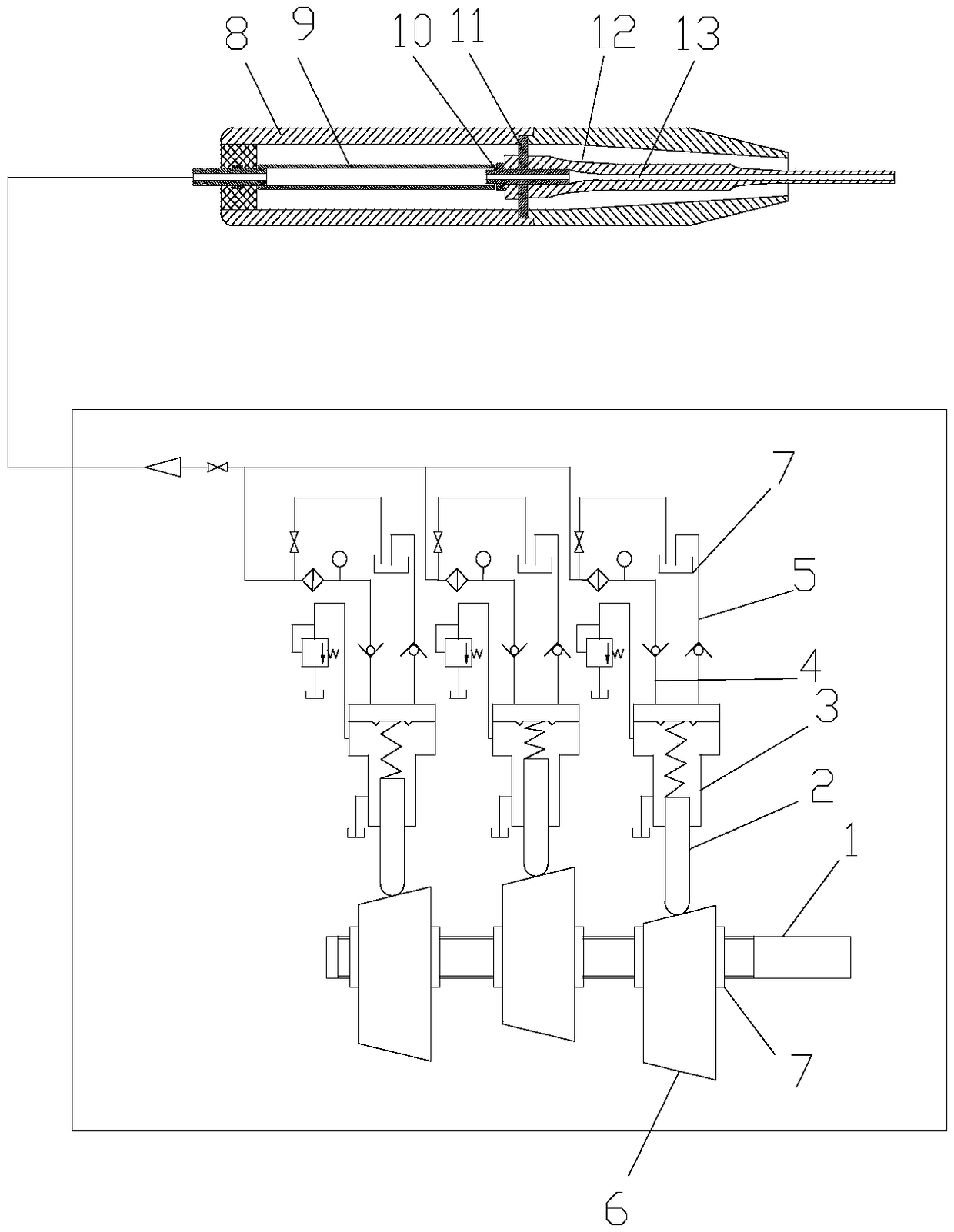

[0020] The debridement liquid pump includes three pumping assemblies, a driving mechanism for driving the pumping assemblies and a nozzle connected to the liquid outlet of the pumping assemblies; the pumping assembly includes a diaphragm pump 3, a debridement pump Wound fluid tank 7, suction pipe 5 and high-pressure pipe 4; the inlet of described diaphragm pump 3 communicates with debridement liquid tank 7 through suction pipe 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com