Method used for preparing limestone powder from building waste concrete

A waste concrete and limestone powder technology is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc. It can solve the problems of occupying cultivated land, destroying vegetation, and deteriorating the ecological environment, so as to reduce resource consumption and environmental pollution. Realize the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

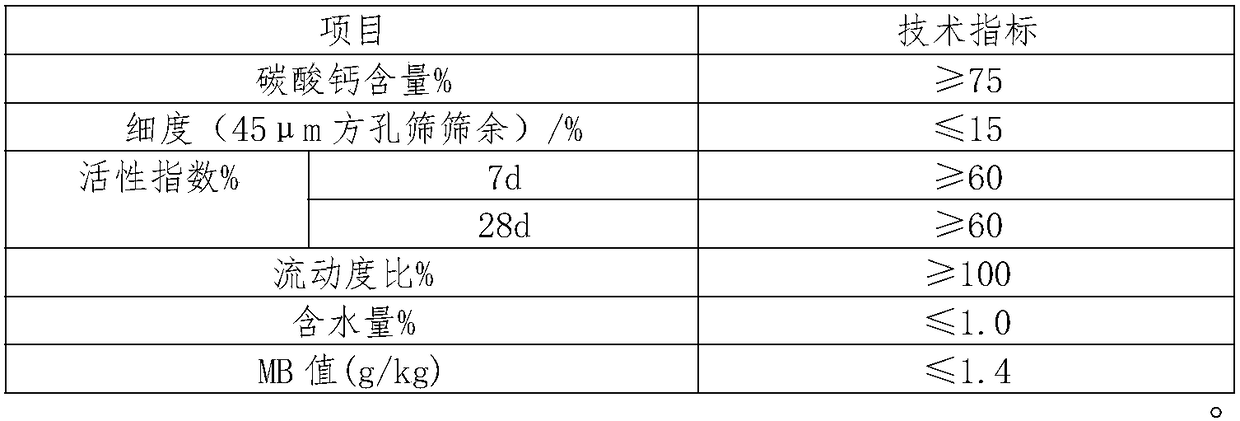

[0025] Weigh 80kg of construction waste concrete containing 70-80% limestone sandstone aggregate, 10kg of limestone, 5kg of slag, and 5kg of silica fume, and mix them to make the materials physically blended and modified, and then crush them with a jaw crusher. Grinding with a type pulverizer until the residue on a 45 μm square hole sieve is 10%, that is, limestone powder.

Embodiment 2

[0027] Weigh 70kg of construction waste concrete, 20kg of limestone, 9kg of slag, and 1kg of silica fume containing 70-80% of limestone sandstone aggregate, mix them to make the materials physically blended and modified, and then crush them with an impact crusher. Grind with a type pulverizer until the residue on a 45 μm square hole sieve is 12%, to obtain limestone powder.

Embodiment 3

[0029] Weigh 75kg of construction waste concrete, 17kg of limestone, 5kg of slag and 3kg of silica fume containing 70-80% of limestone sandstone aggregate, and mix them to make the materials physically blended and modified, and then crush them with a vertical shaft crusher. Grind with a type pulverizer until the residue on a 45 μm square hole sieve is 8%, to obtain limestone powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com