Coal ash powder material recovery system and method for dry mixed mortar production

A technology of coal ash powder and dry-mixed mortar, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., and can solve the pollution of the environment caused by fly ash discharge, waste of resources, and increase of factory costs by fly ash storage yards, etc. problems, achieve the effect of reusing resources and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

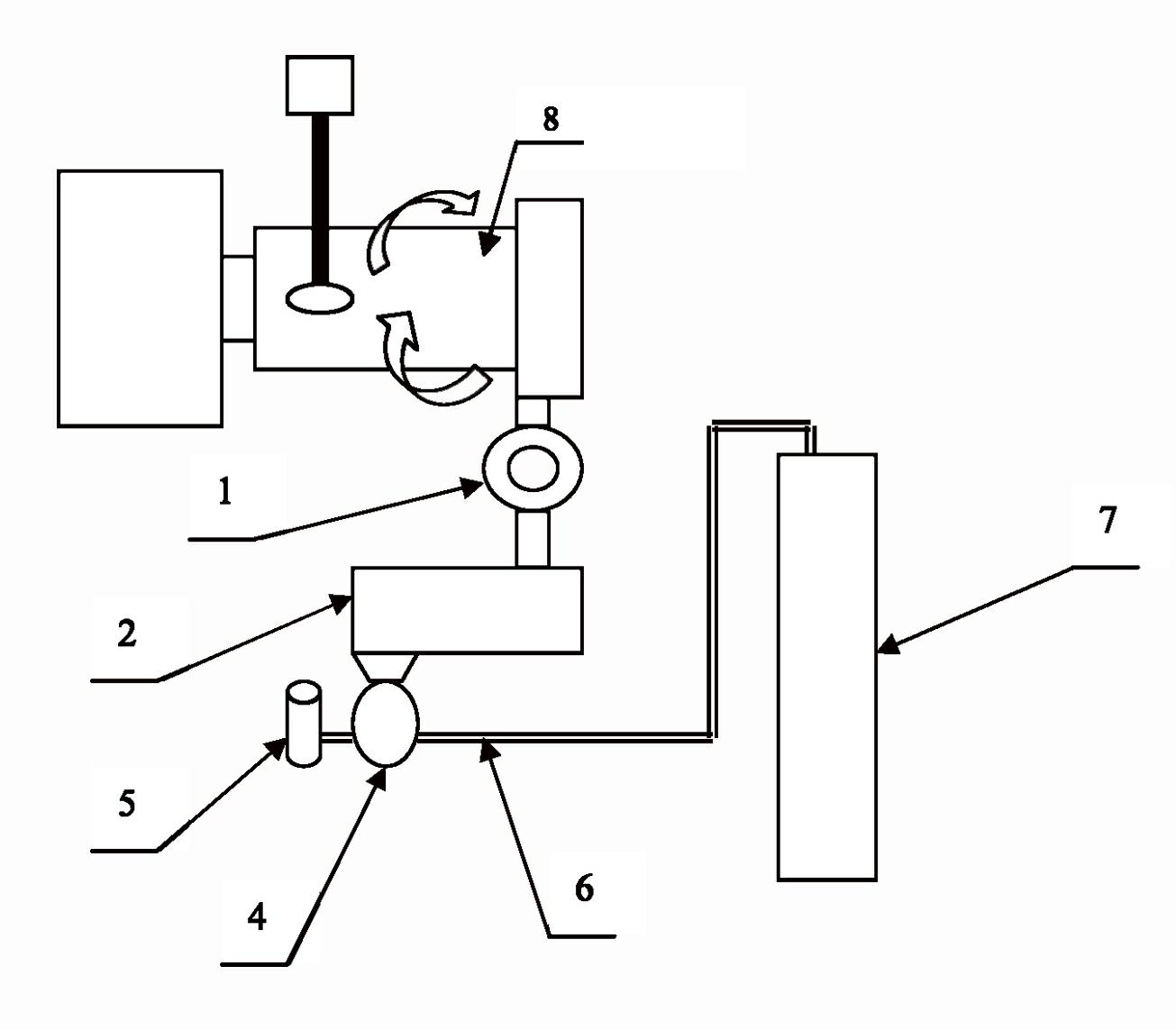

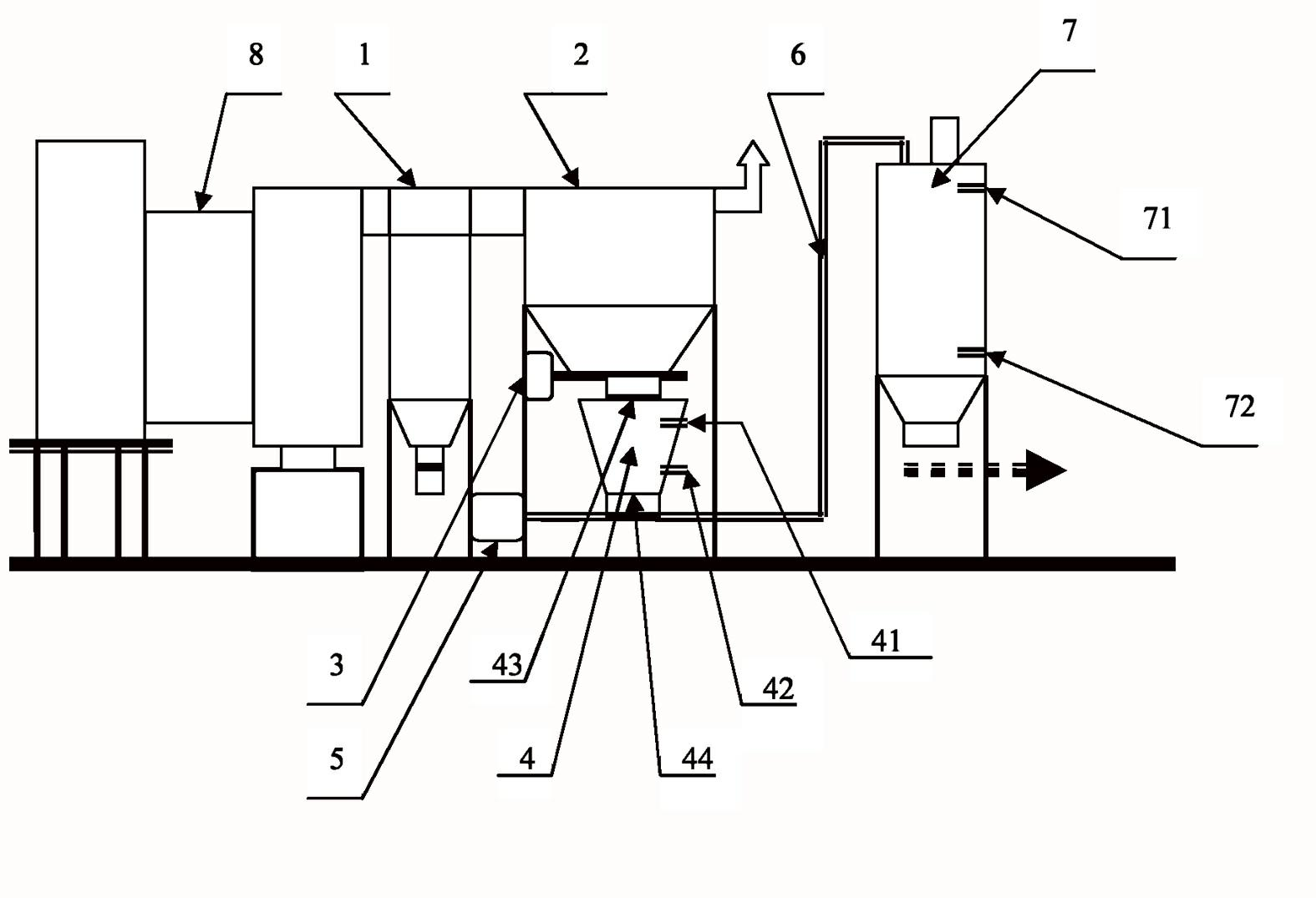

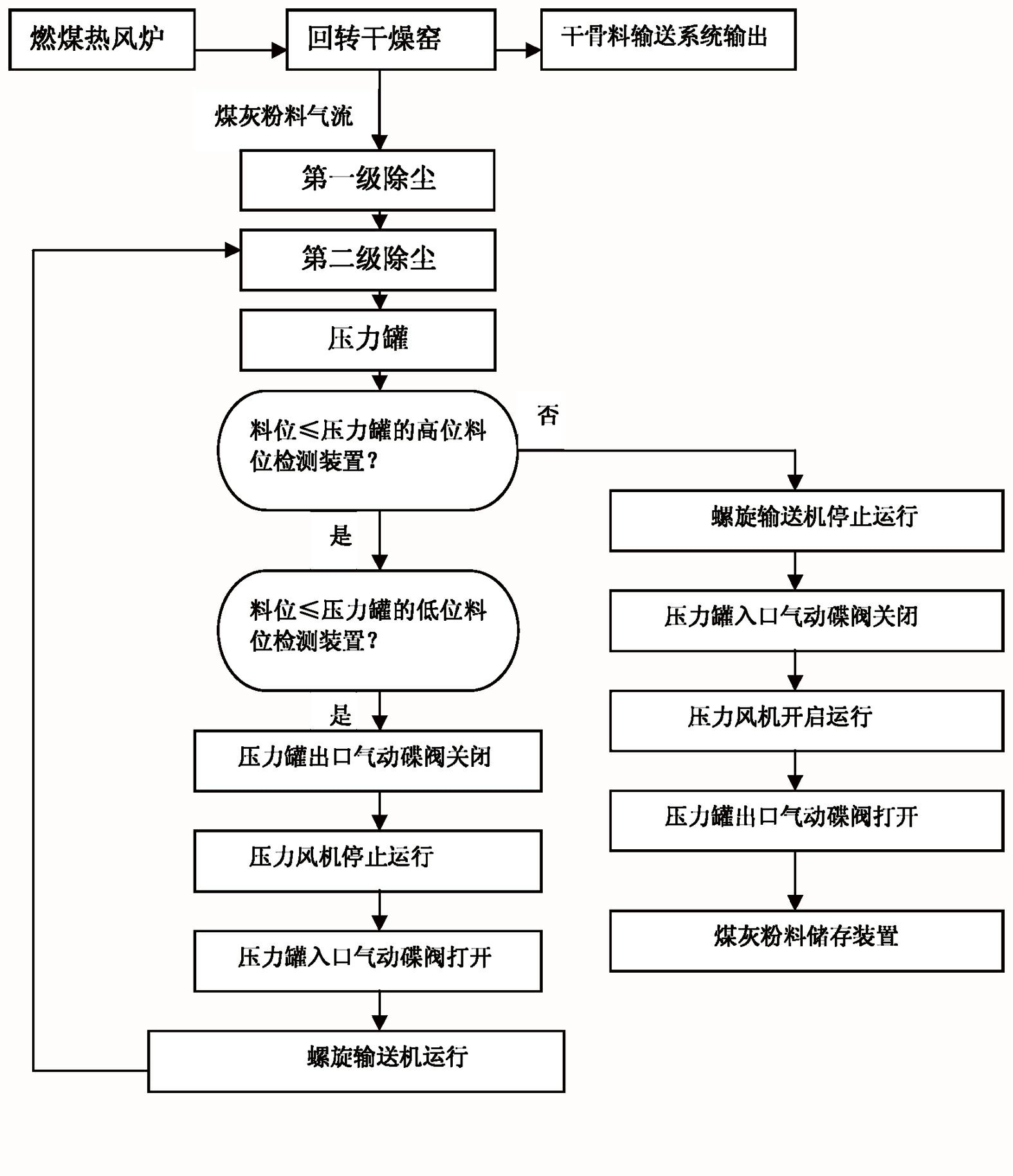

[0036] A coal ash powder recovery system used in the production of dry-mixed mortar, the schematic diagram of the process equipment plane overlooking the structure, please refer to the attached figure 1 , for the schematic diagram of the vertical structure of the process equipment, please refer to the attached figure 2 , including cyclone dust collector 1, box dust collector 2, screw conveyor 3, pressure tank 4, pressure fan 5, pneumatic conveying pipeline 6, coal ash powder storage device 7 and control system (not shown in the figure), cyclone The dust collector 1 is connected to the tail cover of the rotary drying kiln 8 and the inlet of the box-type dust collector 2, and is used to transport the coal ash powder produced by the coal-fired hot blast stove to the box-type dust collector through the rotary drying kiln 8 2. The bottom of the box-type dust collector 2 is connected to the screw conveyor 3. The screw conveyor 3 is used to transport the coal ash powder produced by ...

Embodiment 2

[0041] A coal ash powder recovery system used in the production of dry-mixed mortar, the schematic diagram of the vertical structure of the process equipment can be found in the attached Figure 4 , including cyclone dust collector 1, box dust collector 2, screw conveyor 3, pressure tank 4, closed belt conveyor 9, bucket elevator 10, coal ash powder storage device 7 and control system (not shown in the figure ), the cyclone dust collector 1 is connected to the tail cover of the rotary drying kiln 8 and the inlet of the box-type dust collector 2, and is used to transport the coal ash powder produced by the coal-fired hot blast stove to the box through the rotary drying kiln 8 The bottom of box-type dust collector 2 and box-type dust collector 2 is connected to screw conveyor 3, and screw conveyor 3 is used to transport the coal ash powder produced by box-type dust collector 2 to pressure tank 4, which is equipped with high-level material Level detection device 41, low level mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com