Treatment method for phosphated residues, soil restoration agent and method for reducing content of cadmium in rice

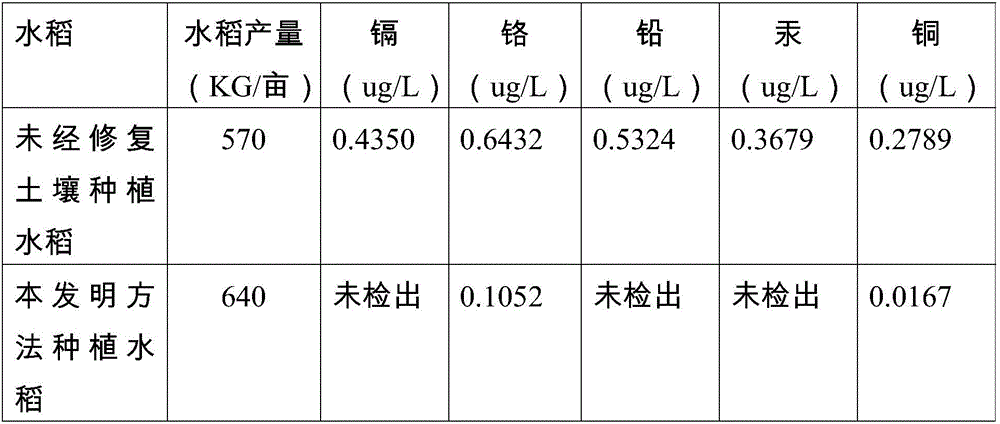

The technology of a soil remediation agent and a treatment method is applied in the field of reducing the cadmium content in rice, which can solve the problems of discarding or discharging with water, environmental pollution and the like, and achieves the effects of reducing the preparation cost, reducing the cadmium content and increasing the growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

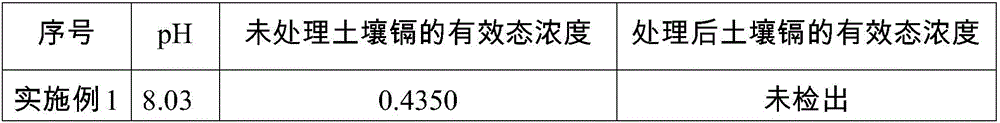

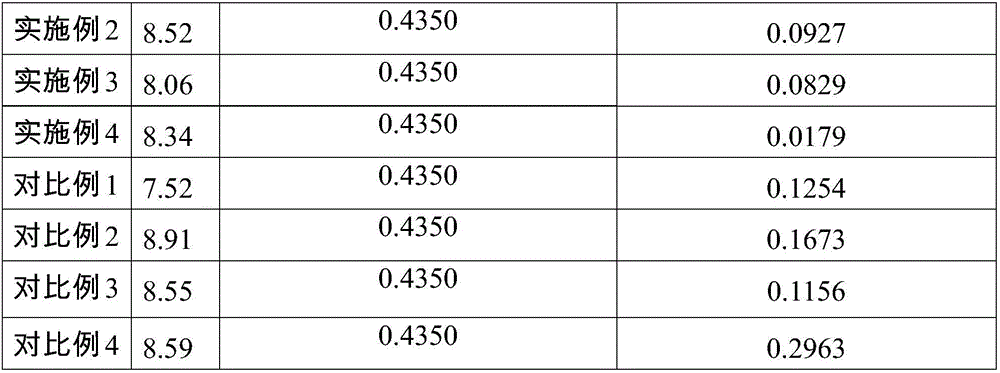

Embodiment 1

[0024] A soil restoration agent, which is prepared by mixing 40% phosphating slag, 5% calcium polysulfide, 3% sulfamic acid, 6% humic acid and 46% silicate clay.

[0025] The appearance of the soil remediation agent is gray granular solid, and the pH is 8.03 when the solid-to-liquid ratio (weight ratio to water) is 1:2.5.

Embodiment 2

[0027] A soil restoration agent, which is prepared by mixing 25% phosphating slag, 6% calcium polysulfide, 5% sulfamic acid, 10% humic acid and 54% silicate clay.

[0028] The appearance of the soil remediation agent is gray granular solid, and the pH is 8.52 when the solid-liquid ratio is 1:2.5.

Embodiment 3

[0030] A soil restoration agent, which is prepared by mixing 20% phosphating slag, 6% calcium polysulfide, 3% sulfamic acid, 6% humic acid and 65% silicate clay.

[0031] The appearance of the soil remediation agent is gray granular solid, and the pH is 8.06 when the solid-liquid ratio is 1:2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com