A dynamic thermal infrared stealth composite material based on double phase transition and its preparation method

A composite material, thermal infrared technology, applied in heat exchange materials, chemical instruments and methods, protective equipment, etc., can solve the problems of increased infrared radiation load, inability to quickly respond to background infrared radiation, etc., to reduce radiation load, respond to Effect of temperature change, overcoming phase change leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step is to take 1kg of vanadium mica raw ore and crush it to mm-level particle size by ball milling, then microwave roasting at 850°C for 1 hour; use sulfuric acid as the leaching solution and mix and stir the roasted clinker at a liquid-solid ratio of 2:1ml / g , leaching reaction at a leaching temperature of 95°C and a leaching time of 12 hours to obtain a vanadium-containing leaching solution. After vanadium extraction, the mica is washed, dried, and set aside; adjust the pH of the leach solution to acidity 2.0, add sodium chlorate to oxidize, and saturate the resin for adsorption, desorption and purification, add ammonium salt to precipitate to form ammonium metavanadate, filter, wash, and dry; Ammonium vanadate was used as the reaction raw material, and 0.8ml / L oxalic acid reducing agent solution was added dropwise to ammonium metavanadate, and after stirring for 10 minutes, the hydrothermal reaction was carried out at a reaction temperature of 180°C for 12 ...

Embodiment 2

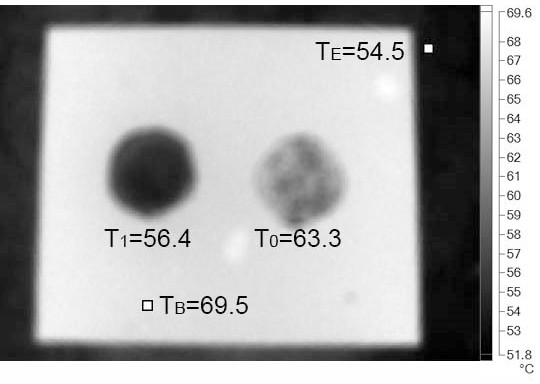

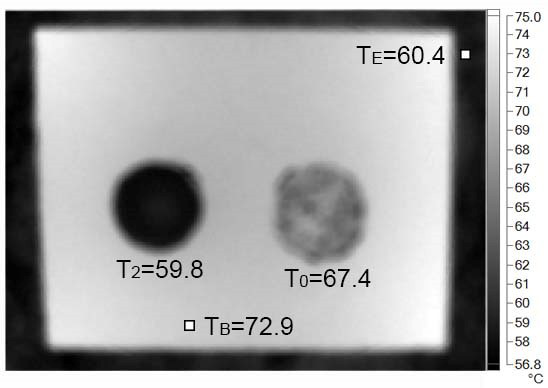

[0034] According to the same method and condition of Example 1 (but change the mass ratio of stearic acid and mica after vanadium extraction to 4:6, prepare mica-based phase-change heat storage composite material, and obtain mica-based phase-change heat storage thin layer), in the same Spin coating VO under spin coating times 2 Nanoparticles, finally obtained to prepare VO 2 / mica-based phase change heat storage thin-layer composite material, denoted as sample 2. Its infrared stealth performance is tested by the infrared camera FlukeThermography TiS50. According to the infrared stealth evaluation standard, the test method is as follows: put the obtained dual phase change material (sample 2) and the pure phase change material (sample 0) in comparative example 1 into glass molds and put them on a rectangular heating plate at 68-73°C. After a period of time, ,Such as figure 2 As shown in the grayscale image of the infrared thermal image, the temperature of the plate is T B ...

Embodiment 3

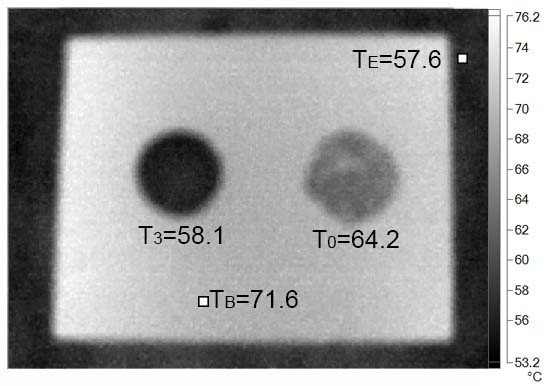

[0036] According to the same method and condition of Example 1 (but change the mass ratio of stearic acid and mica after vanadium extraction to 5:5, prepare the mica-based phase-change heat storage composite material, and obtain the mica-based phase-change heat storage thin layer), in the same Spin coating VO under spin coating times 2 Nanoparticles, finally obtained to prepare VO 2 / mica-based phase change heat storage thin-layer composite material, denoted as sample 3. Its infrared stealth performance is tested by the infrared camera FlukeThermography TiS50. According to the infrared stealth evaluation standard, the test method is as follows: put the obtained double phase change material (sample 3) and the pure phase change material (sample 0) in comparative example 1 into a glass mold and put them on a rectangular heating plate at 68-73°C. After a period of time, ,Such as image 3 As shown in the grayscale image of the infrared thermal image, the temperature of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com