Quick repairing method for perforation of coke oven wall

A repair method and furnace wall technology, which are applied in the direction of preventing/repairing the leakage of bricklaying, etc., can solve the problems of reducing the temperature of the furnace wall, secondary damage, potential safety hazards, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide a quick repair method for coke oven wall perforation, which can improve the hot repair efficiency, reduce the labor intensity of workers, and reduce the damage to the furnace wall.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

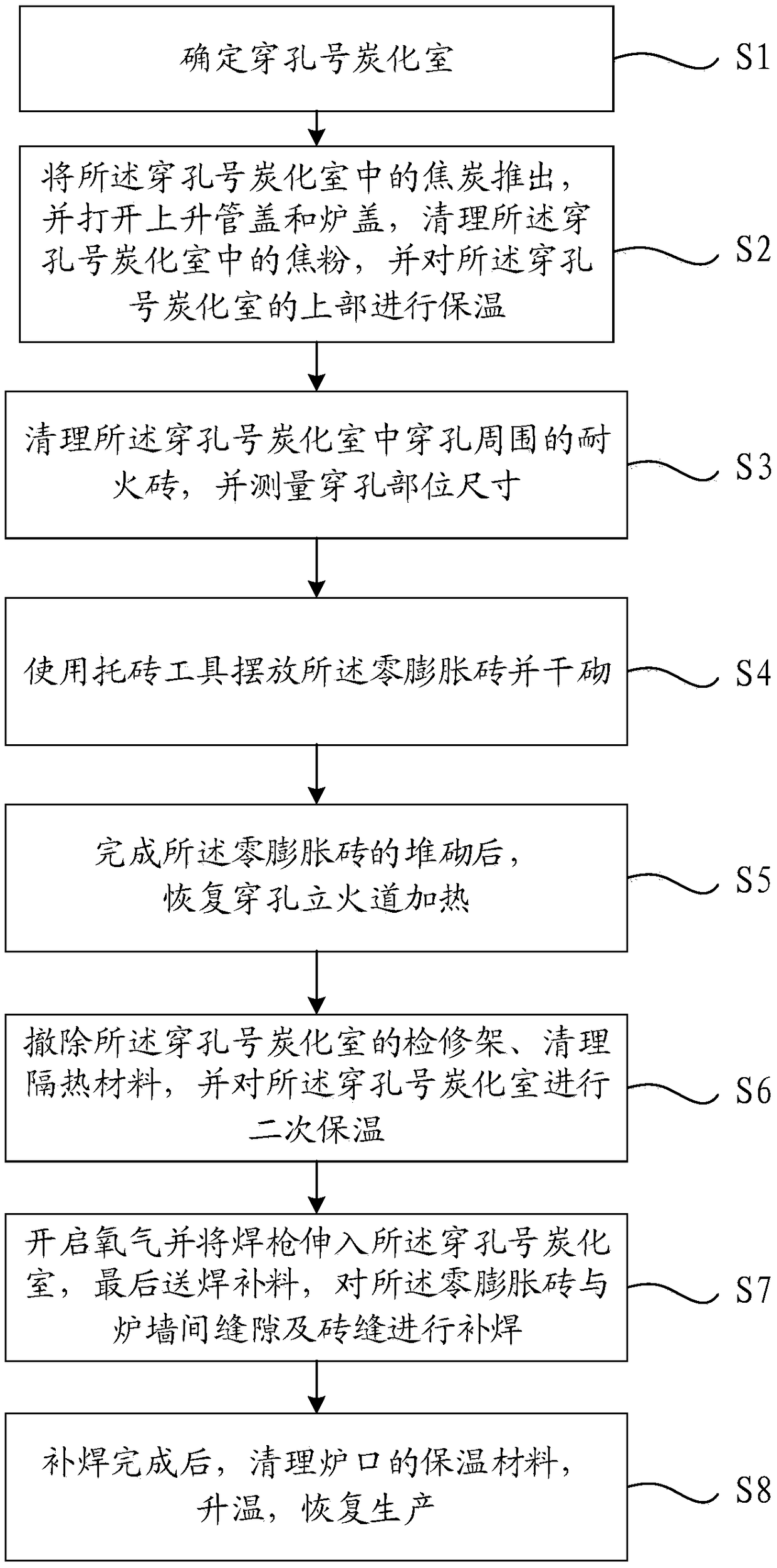

[0036] Please refer to figure 1 , figure 1 It is a flow chart of a specific embodiment of the rapid repair method for coke oven wall perforation provided by the present invention.

[0037] In this embodiment, the rapid repair method for coke oven wall perforation includes the following steps:

[0038] Step S1: Determine the carbonization chamber of the perforation number, and cool down the carbonization chamber of the perforation number 2-3 hours in advance to a temperature of 1200±100°C correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com