Method for increasing biomass of bacicllus natto at high temperature

A technology of biomass and Bacillus natto, which is applied in the field of bioengineering, can solve the problems of affecting the physiological activity of cells, reducing the biomass of Bacillus natto, inhibiting the growth performance and metabolic activity of bacteria, and achieving the improvement of biomass and good growth performance , effective and rapid biomass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] Preparation of corn peptide aqueous solution: Weigh a certain amount of plump corn kernels and grind them into corn flour, put them into a 1L Erlenmeyer flask, and use phosphate buffer (concentration: 0.1moi / L, PH=6.8) to make a mass fraction of 5%. The corn flour suspension, stirred evenly, put it into a constant temperature water bath shaker to 55 ° C, and adjusted the pH value to 8.5; add alkaline protease according to the enzyme amount of 4% of the mass ratio of the enzyme to the corn flour suspension, and hydrolyze for 1.5h ; Maintain the pH value at 8.5 with 4mol / L NaOH aqueous solution. Put the triangular flask in a 90°C water bath and keep it for 15 minutes to inactivate the enzyme; take out the triangular flask, rapidly cool down at room temperature, centrifuge at 4000r / min for 10min to get the supernatant, filter it through a 0.22μm filter membrane, freeze-dry the filtrate to obtain corn peptide powder.

[0014] The corn peptide powder is dissolved in sterile...

Embodiment 1

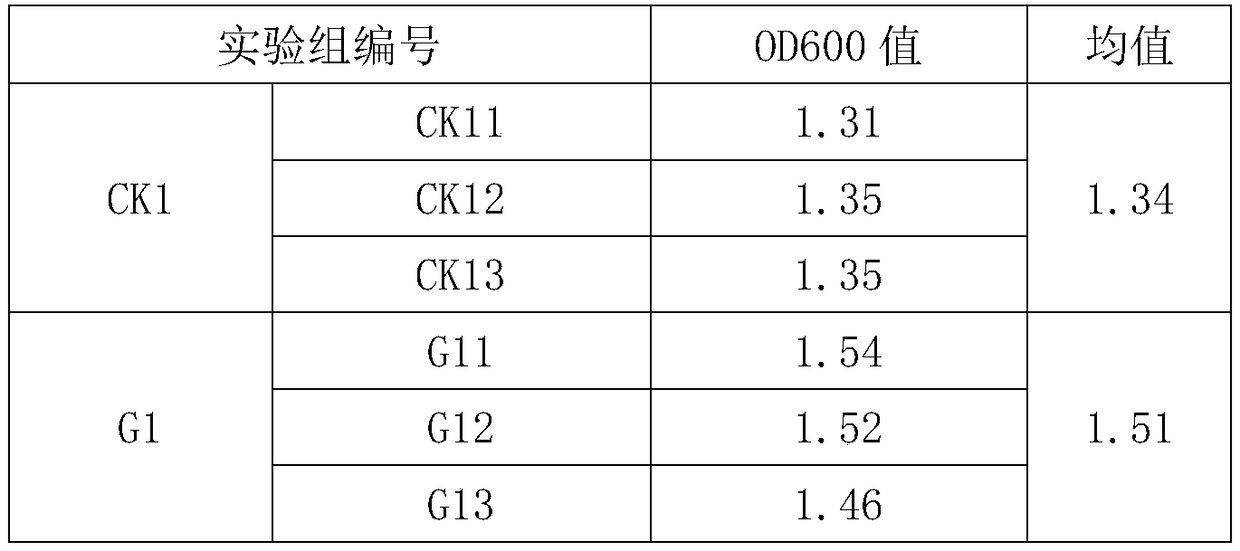

[0017] Example 1 (G1)

[0018] A method for improving the biomass of Bacillus natto under high temperature conditions, comprising the steps of:

[0019] (1) Take 10ul of Bacillus natto glycerol stock solution preserved at -20°C and inoculate it in 50ml seed culture medium, and culture it at 37°C on a shaker at 200r / min for 6h; The corn peptide aqueous solution with a concentration of 0.15g / ml was cultured on a shaker at 200r / min at 37°C for 6h to obtain a seed solution;

[0020] (2) The seed solution was inoculated in the fermentation medium at an inoculum amount of 2%, and cultured on a shaker at 200 r / min at 53° C. for 30 h.

[0021] Embodiment 1 is 3 parallel.

Embodiment 2

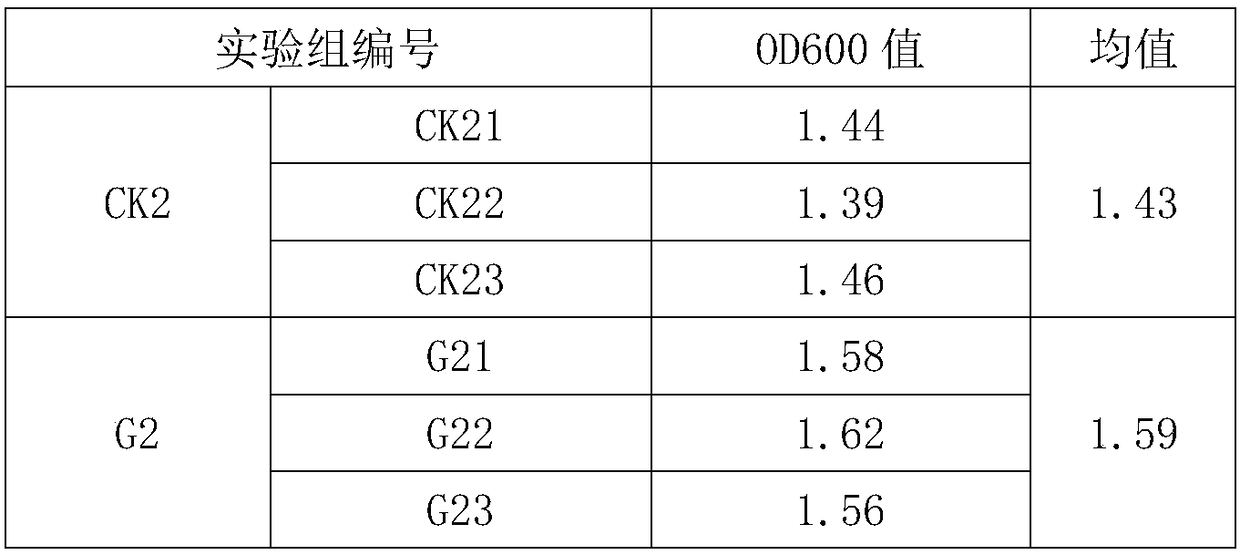

[0031] Example 2 (G2)

[0032] A method for improving the biomass of Bacillus natto under high temperature conditions, comprising the steps of:

[0033] (1) Take 10ul of Bacillus natto glycerol stock solution preserved at -20°C and inoculate it in 50ml seed culture medium, and cultivate it at 37°C for 4h on a shaker at 150r / min; A corn peptide aqueous solution with a concentration of 0.2g / ml was cultured on a shaker at 150r / min at 37°C for 4 hours to obtain a seed solution;

[0034] (2) The seed solution was inoculated in the fermentation medium at an inoculation amount of 1%, and cultured on a shaker at 150 r / min at 50° C. for 36 hours.

[0035] Embodiment 2 is 3 parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com