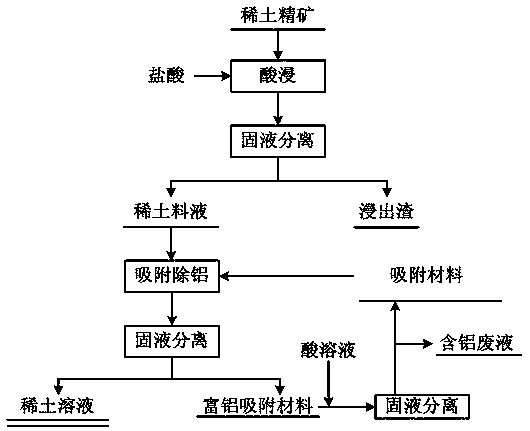

Method for removing aluminum from rare earth material solution by organic acid complexation and solid-phase adsorption

A technology of solid-phase adsorption and rare earth feed liquid, which is applied in the fields of chemistry, hydrometallurgy, and materials, can solve the problems of difficult separation of rare earth and aluminum, and achieve the effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Rare earth concentrate hydrochloric acid leaching solution: aluminum content 0.96g / L (as Al 2 o 3 ), the rare earth content is 92 g / L (based on REO), and the pH of the solution is 1.5.

[0034] (2) Pipette 100mL of leachate into a 300mL Erlenmeyer flask, put it into a constant temperature water bath with magnetic stirring, weigh 5.5291g of sodium citrate into the Erlenmeyer flask, stir and react at a constant temperature of 20°C for 60min, then add 10% NaOH The solution slowly adjusts the pH of the rare earth solution to 3.0.

[0035] (3) Add 0.2g of activated carbon into the solution, shake it at constant temperature for 30 minutes, and then filter it. The aluminum content in the solution after adsorption is 0.13g / L, the removal rate of aluminum is 85%, and the loss of rare earth is 4.7%.

Embodiment 2

[0037] (1) Rare earth concentrate hydrochloric acid leaching solution: aluminum content 1.68g / L (as Al 2 o 3 ), the rare earth content is 78 g / L (based on REO), and the pH of the solution is 1.5.

[0038] (2) Pipette 100mL of leaching solution into a 300mL Erlenmeyer flask, put it into a constant temperature water bath with magnetic stirring, weigh 4.5628 g of citric acid and add it to the Erlenmeyer flask, stir and react at a constant temperature of 30°C for 90min, add ammonia water to slowly adjust the rare earth solution pH=3.5.

[0039] (3) Add 0.35g of porous polyvinylbenzene resin into the solution, shake it at constant temperature for 45 minutes, and then filter it. The aluminum content in the solution after adsorption is 0.16g / L, the removal rate of aluminum is 90%, and the loss of rare earth is 4.9%.

Embodiment 3

[0041] (1) Rare earth concentrate hydrochloric acid leaching solution: aluminum content 1.178g / L (as Al 2 o 3 ), the rare earth content is 100 g / L (based on REO), and the pH of the solution is 2.0.

[0042] (2) Pipette 100mL of leaching solution into a 300mL Erlenmeyer flask, put it into a constant temperature water bath with magnetic stirring, weigh 15.18 g of disodium citrate and add it to the Erlenmeyer flask, stir at 40°C for 120min, add ammonia water to slowly adjust Rare earth solution pH=3.5.

[0043] (3) Add 0.3g of activated carbon into the solution, react with constant temperature oscillation for 60min, and then filter. The aluminum content in the solution after adsorption is 0.24g / L, the removal rate of aluminum is 80%, and the loss of rare earth is 3.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com