A preparation method of tungsten alloy precursor composite powder, tungsten alloy and preparation method

A technology of composite powder and tungsten alloy, applied in the field of tungsten alloy, can solve the problems of uneven distribution and easy segregation, and achieve the effect of improving uniformity and high temperature wear resistance and erosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

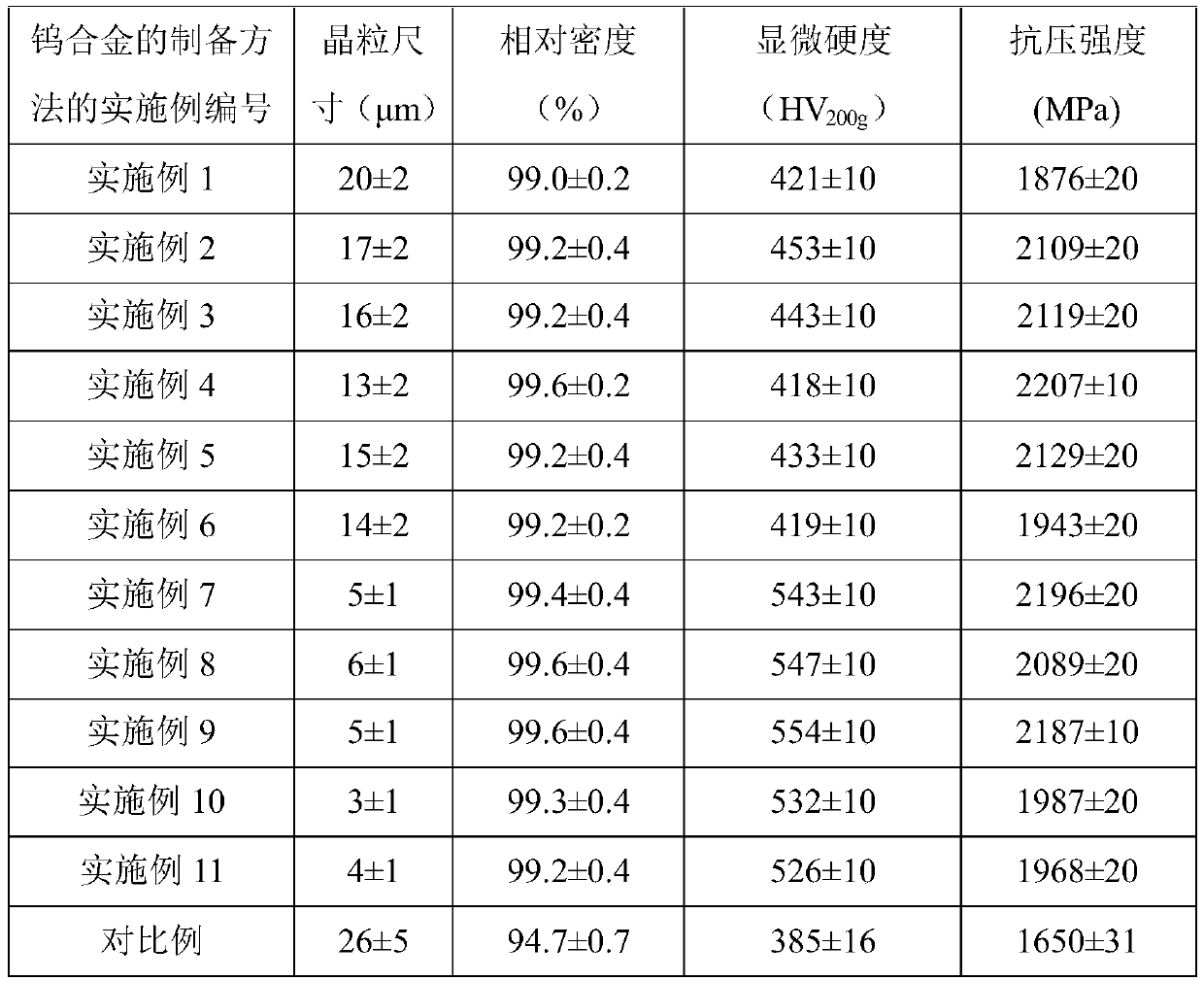

Examples

preparation example Construction

[0025] The uniformity of each component in the tungsten alloy has an important influence on the performance of the tungsten alloy itself. In order to improve the performance in the tungsten alloy, the present invention improves a preparation method of the tungsten alloy precursor composite powder, which includes the following steps:

[0026] A mixed solution of ammonium metatungstate and soluble aluminum salt is provided, oxalic acid is added to the mixed solution until the pH is not greater than 1.5, the reaction is complete, and then the solvent is removed to obtain a mixed powder.

[0027] The preparation method of the tungsten alloy precursor composite powder of the present invention adopts oxalic acid to adjust pH after liquid-liquid mixing, hydrogen ions and tungstate ions in the solution will react to form tungstic acid precipitation; oxalate ions and aluminum ions react to form oxalic acid Aluminum precipitation, due to the co-reaction of tungstic acid and aluminum oxal...

Embodiment 1

[0052] The preparation method of the tungsten alloy precursor composite powder of the present embodiment comprises the following steps:

[0053] 1) 138.0kg ammonium metatungstate (AMT) and 1.34kg aluminum sulfate [Al 2 (SO 4 ) 3 ] was dissolved in 45.5L distilled water, and a mixed solution was obtained after all the solids were dissolved;

[0054] Add oxalic acid to the obtained mixed solution to adjust pH=1.5, and then heat it in a water bath at 100°C. After the temperature of the mixed solution rises to 100°C, continue to heat it in a water bath at 100°C, and keep stirring the mixed solution during the heating process. The reaction is complete, suction filtered and dried to obtain a mixed powder;

[0055] 2) Spread the obtained mixed powder into a material layer with a thickness of 2 mm and then calcinate at 550 ° C for 1 h, then place the calcined product in a tubular reduction furnace, spread it into a material layer with a thickness of 3 mm, and then pass in hydrogen ...

Embodiment 2

[0057] The preparation method of the tungsten alloy precursor composite powder of the present embodiment comprises the following steps:

[0058] 1) Combine 137.45kg ammonium metatungstate (AMT) and 10.53kg aluminum sulfate [Al 2 (SO 4 ) 3 ] was dissolved in 49.33L distilled water, and a mixed solution was obtained after all the solids were dissolved;

[0059] Add oxalic acid to the obtained mixed solution to adjust the pH=1.5, and then use a 90°C water bath to heat it. After the temperature of the mixed solution rises to 90°C, continue to use a 90°C water bath to heat the mixed solution. During the heating process, the mixed solution is always stirred. The reaction is complete, suction filtered and dried to obtain a mixed powder;

[0060] 2) Spread the obtained mixed powder into a material layer with a thickness of 6 mm and then calcinate at 550 ° C for 1.5 h, then place the calcined product in a tubular reduction furnace, spread it into a material layer with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com