Bionic design method making centrifugal pump have resistance reducing and noise lowering performance

A design method and technology of centrifugal pumps, which are applied to components, pumps, and calculations of pumping devices for elastic fluids, can solve problems such as time-consuming, energy-intensive and labor costs, no design solutions are provided, and the process is cumbersome and complicated, etc., to achieve Simple design formula, good pressure pulsation, easy and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

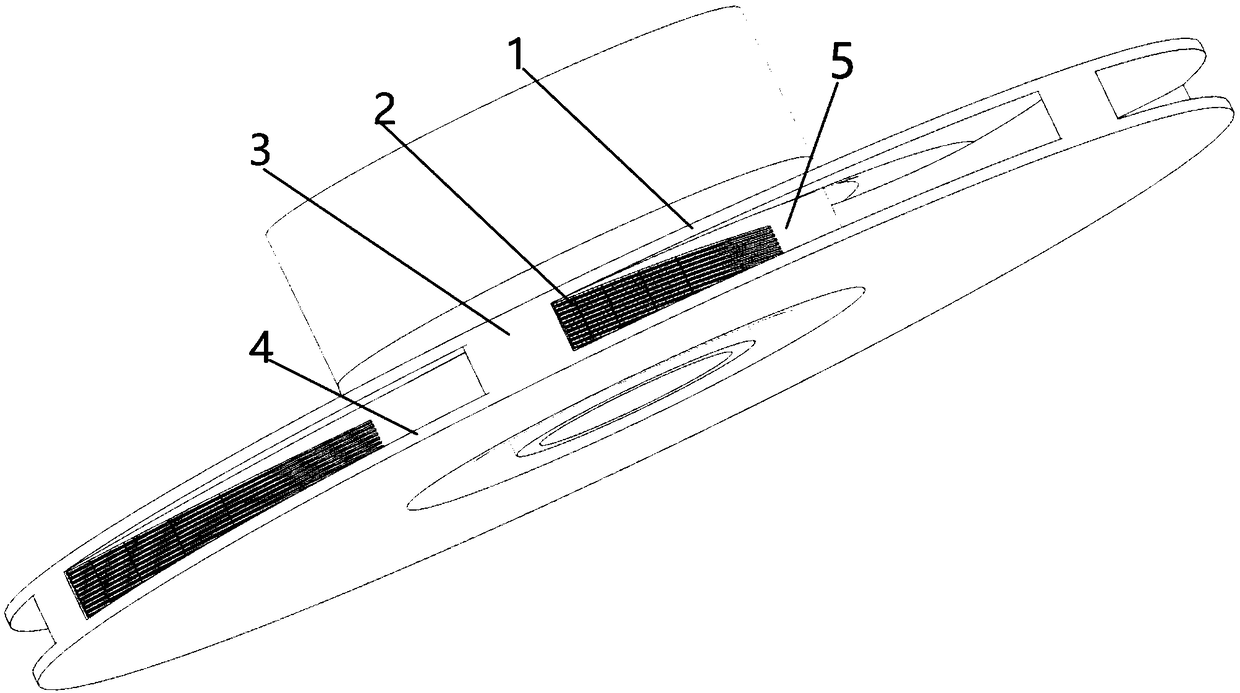

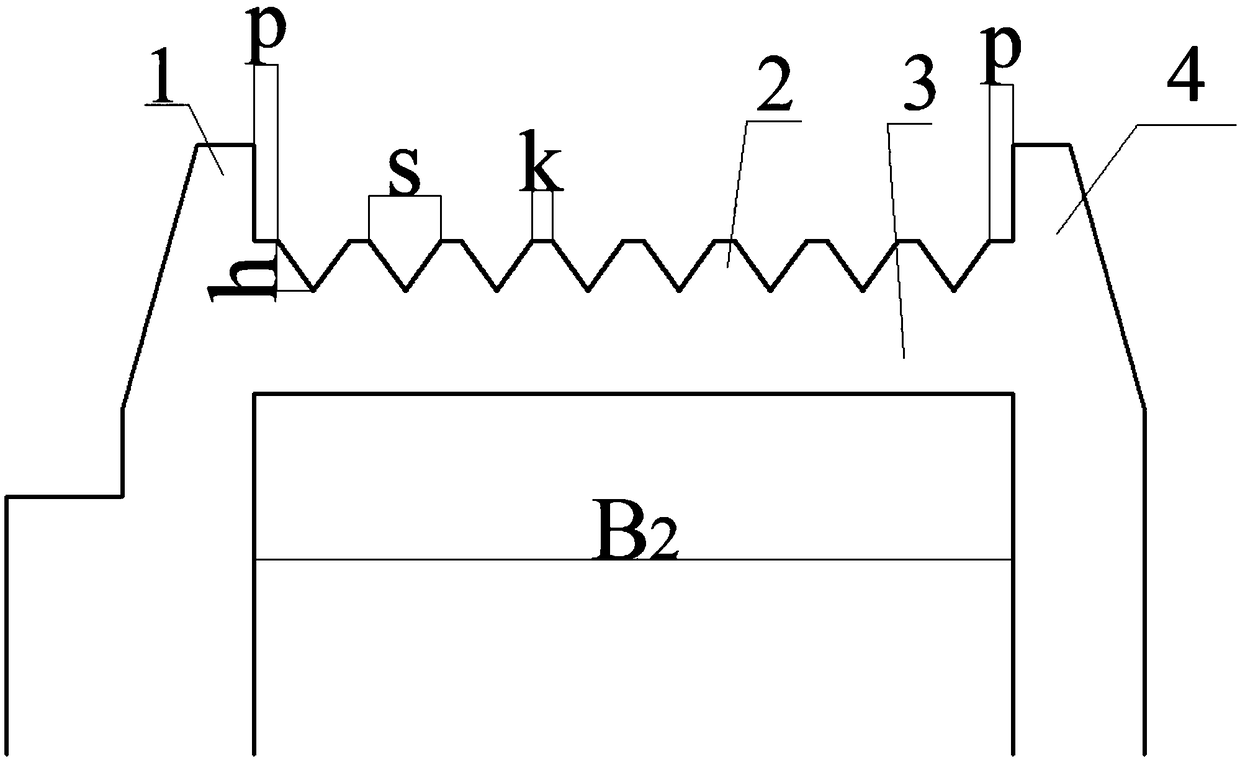

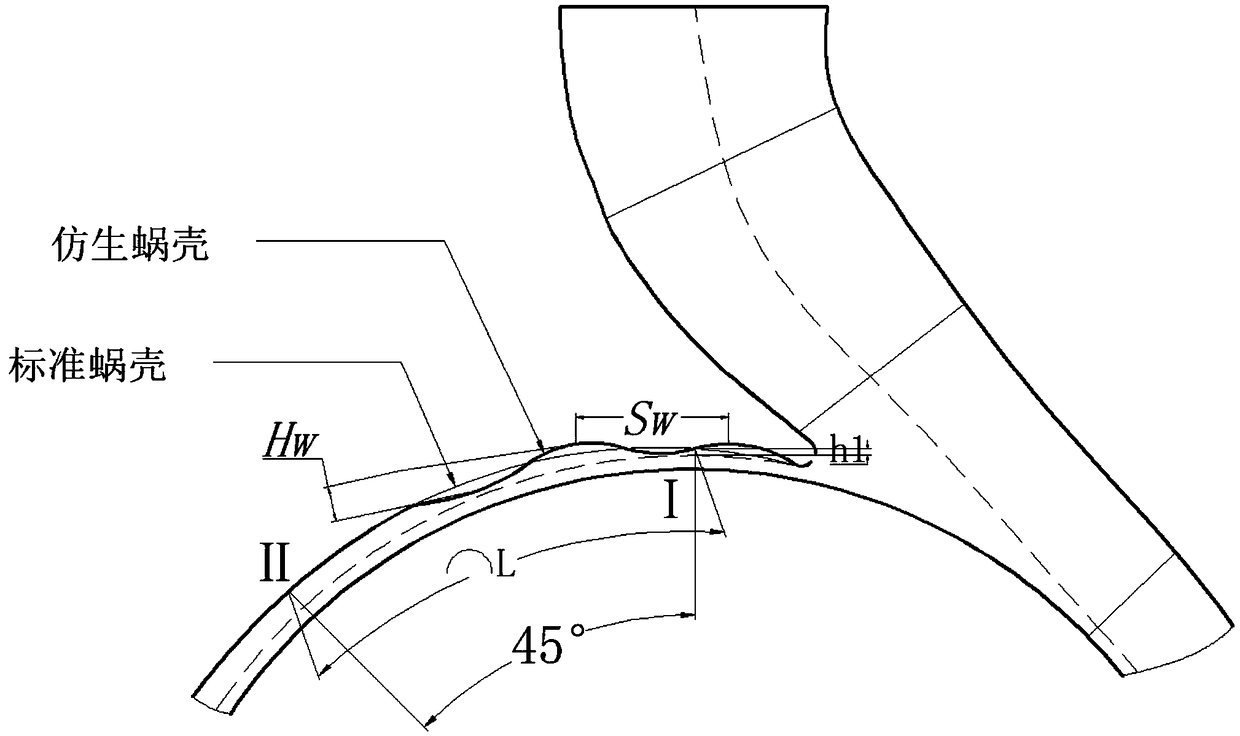

[0055] Such as figure 1 As shown, in this embodiment, a closed structure smooth centrifugal pump is used for bionic design. The smooth centrifugal pump mainly includes an impeller and a volute. The specific parameters of the smooth centrifugal pump are: flow rate Q=25m3 / h=0.006944m 3 / s, head H=10m, speed n=1450r / min, specific speed n s =78.4, the diameter D of the impeller outlet 3 of the model pump 2 is 0.2m, the width B of the impeller outlet 3 2 is 0.008m, the arc length L of the cross-section curve between the first and second sections of the standard volute outer profile is 0.31m, and the height between the outer contour curve and the base circle at the first section of the volute is h 1 0.01m, Section I is the cross section where the centerline of the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com