External force triggered type response enhanced self-powered gas sensor and preparation method thereof

A gas sensor and triggering technology, applied in the field of sensors, can solve problems such as threatening the life safety of maintenance personnel, hindering the application of flammable and explosive gases, increasing operating costs, etc., to improve quantum efficiency, improve gas sensor response rate and sensitivity, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

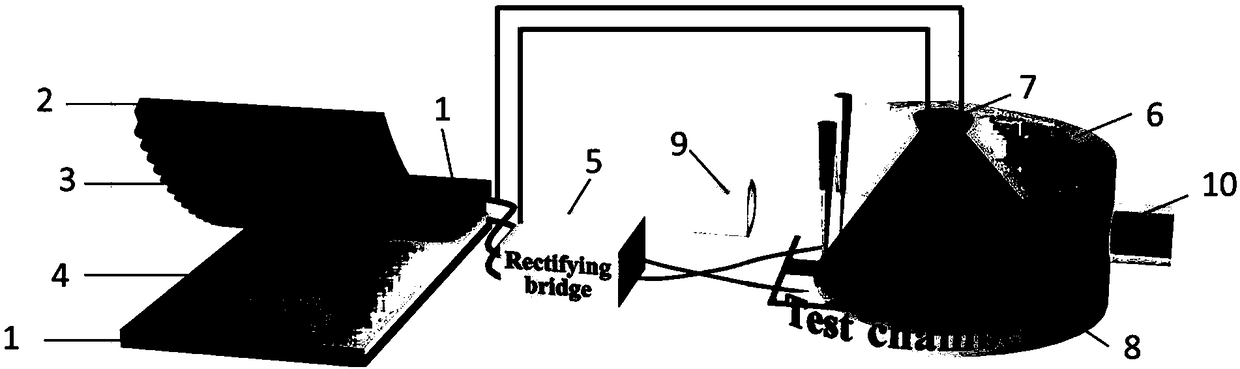

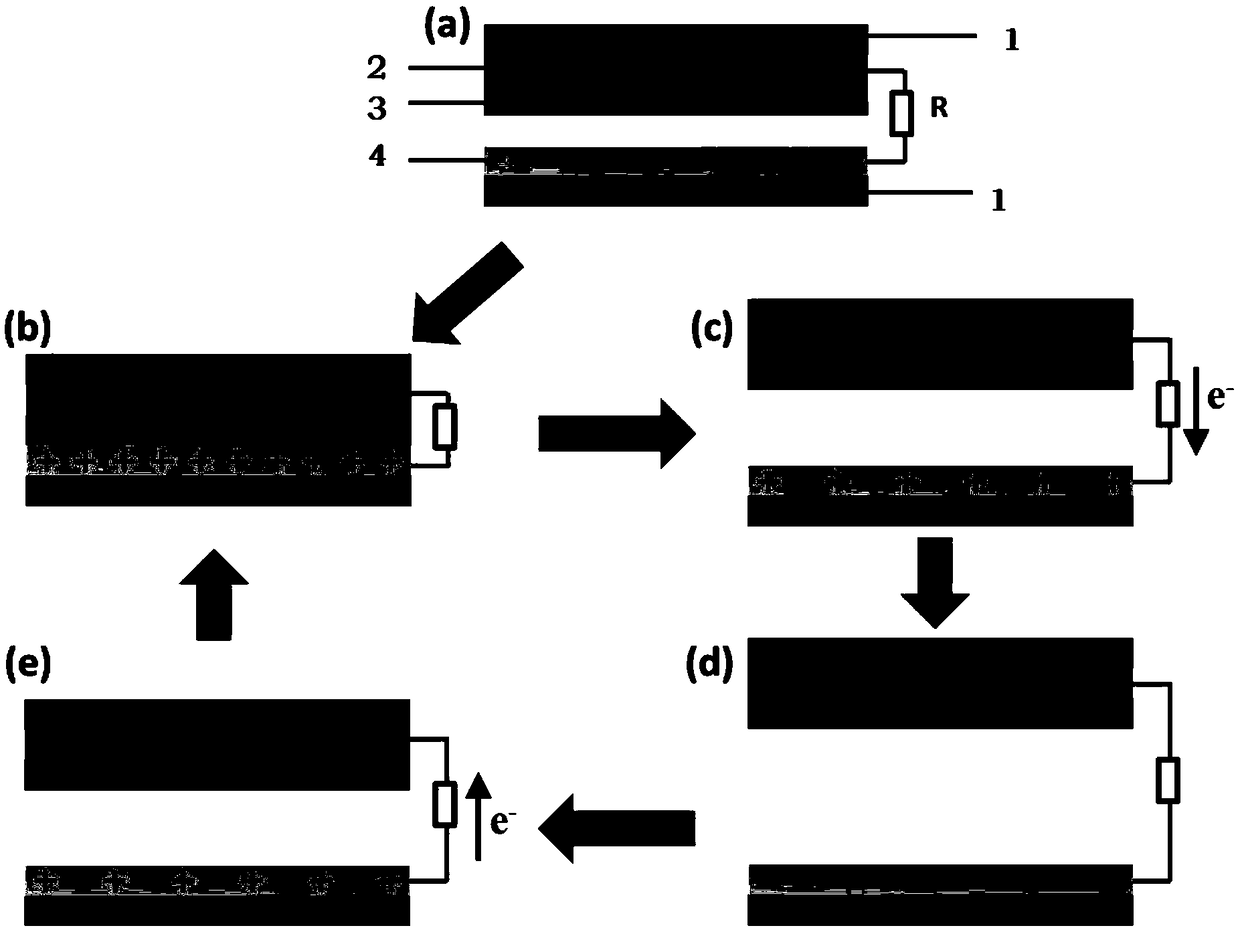

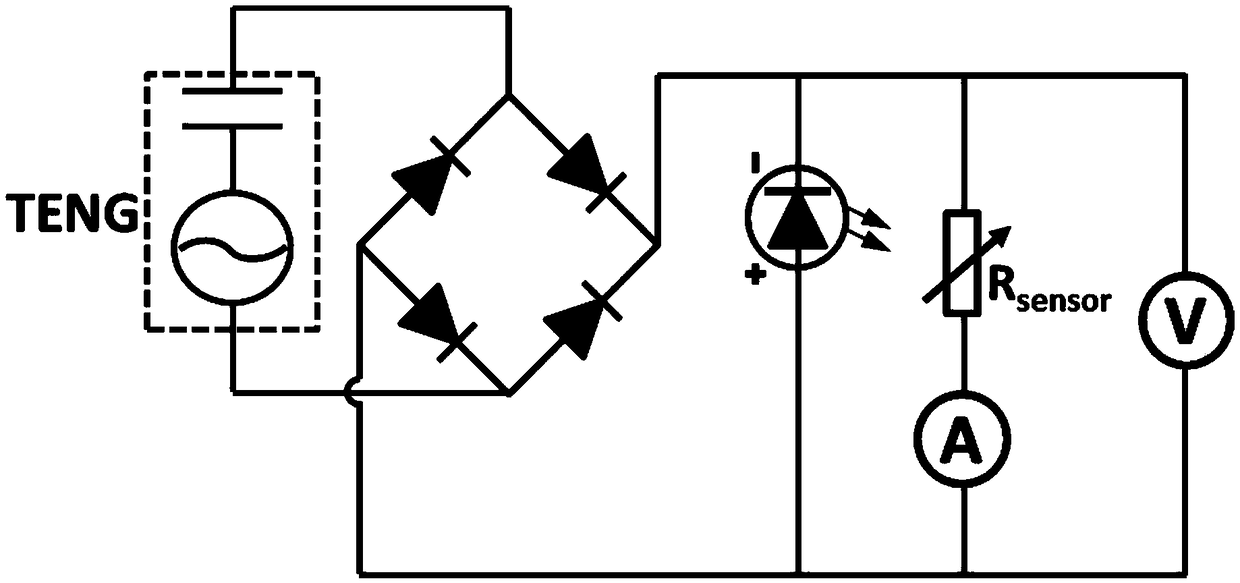

[0042] This embodiment provides a self-powered gas sensor, the structure of which is as follows figure 1 As shown, it includes a gas sensor, a triboelectric nanogenerator and a detection circuit arranged in the test chamber 6; the test chamber 6 is provided with an air inlet 9 and an air outlet 10 for the detection gas to pass in and out; the gas The sensitive element adopts a resistive interdigital electrode structure, specifically an interdigital electrode 8 deposited with a gas-sensitive film; The second friction member below the friction member, the first friction member includes a PET film with a thickness of 10 microns to 50 microns and a metal copper film 2 deposited on the upper surface of the PET film 1, and the second friction member includes a thickness of 10 microns. A PTFE film 3 of micron to 50 microns and a metal aluminum film 4 deposited on the lower surface of the PTFE film 3, the first friction part and the second friction part are separated from each other b...

Embodiment 2

[0045] This embodiment provides a method for preparing a self-powered gas sensor, and the specific process flow is as follows:

[0046] (1) The flexible substrate is cleaned with chemical reagents, and the flexible substrate is dried after cleaning.

[0047] (2) The present embodiment adopts the contact-separation type frictional nanometer power generation device as the passive power supply unit, and the triboelectrode sequence of the friction layer used to realize the contact-separation of the contact-separation type frictional nanometer power generation device should have differences, and the contact-separation type The friction part that realizes contact-separation of the type triboelectric nanometer power generation device is preferably a flexible material that is easily disturbed by external force; in this embodiment, PET film is selected as the substrate, and PTFE film 3 and metal aluminum film 4 are selected as the contact-separation parts respectively. The friction lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com