Liquid medicine extruding machine

A technology of extruder and liquid medicine, which is applied to mixers, mixer accessories, cleaning hollow objects, etc., can solve the problems of increasing the labor intensity of staff, difficult to ensure the safety of medicines, affecting production efficiency, etc., so as to reduce the pollution of medicines. risk, eliminate external pollution, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

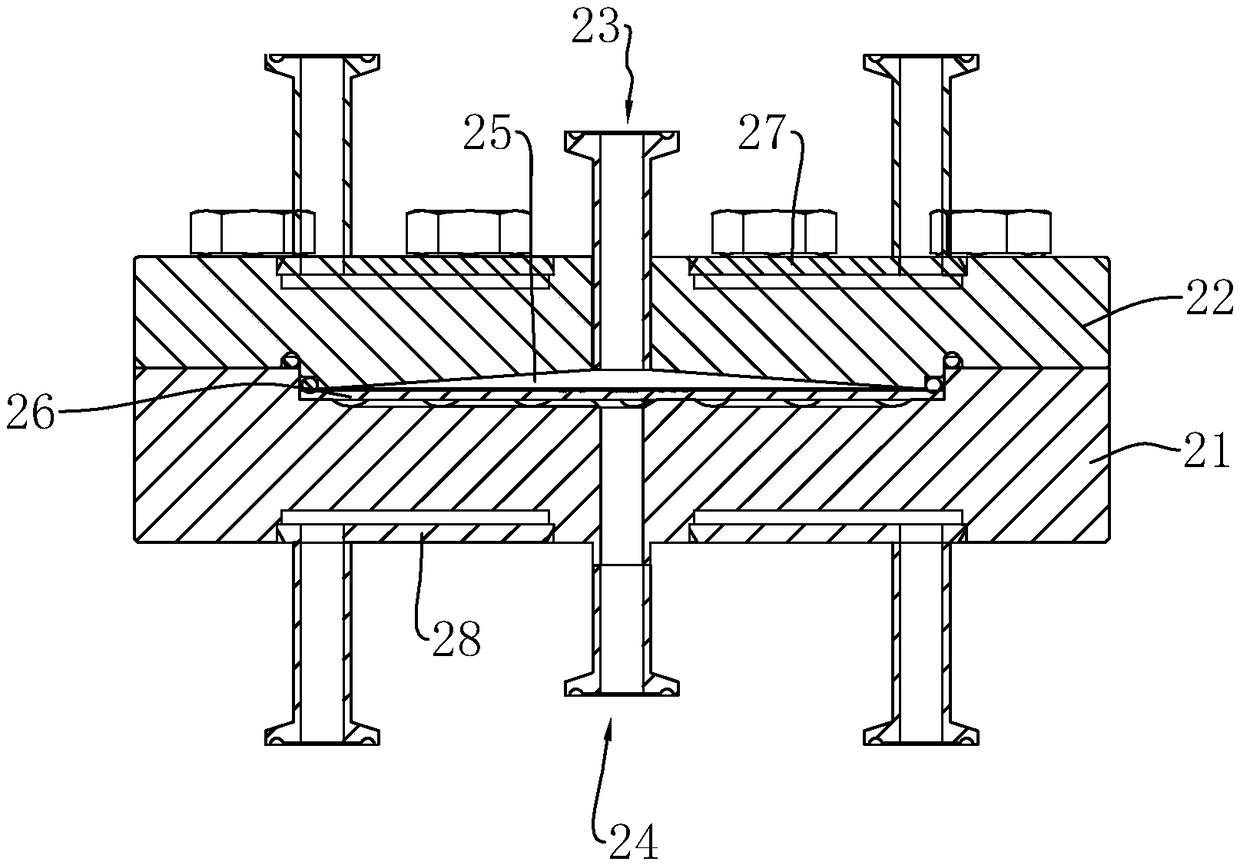

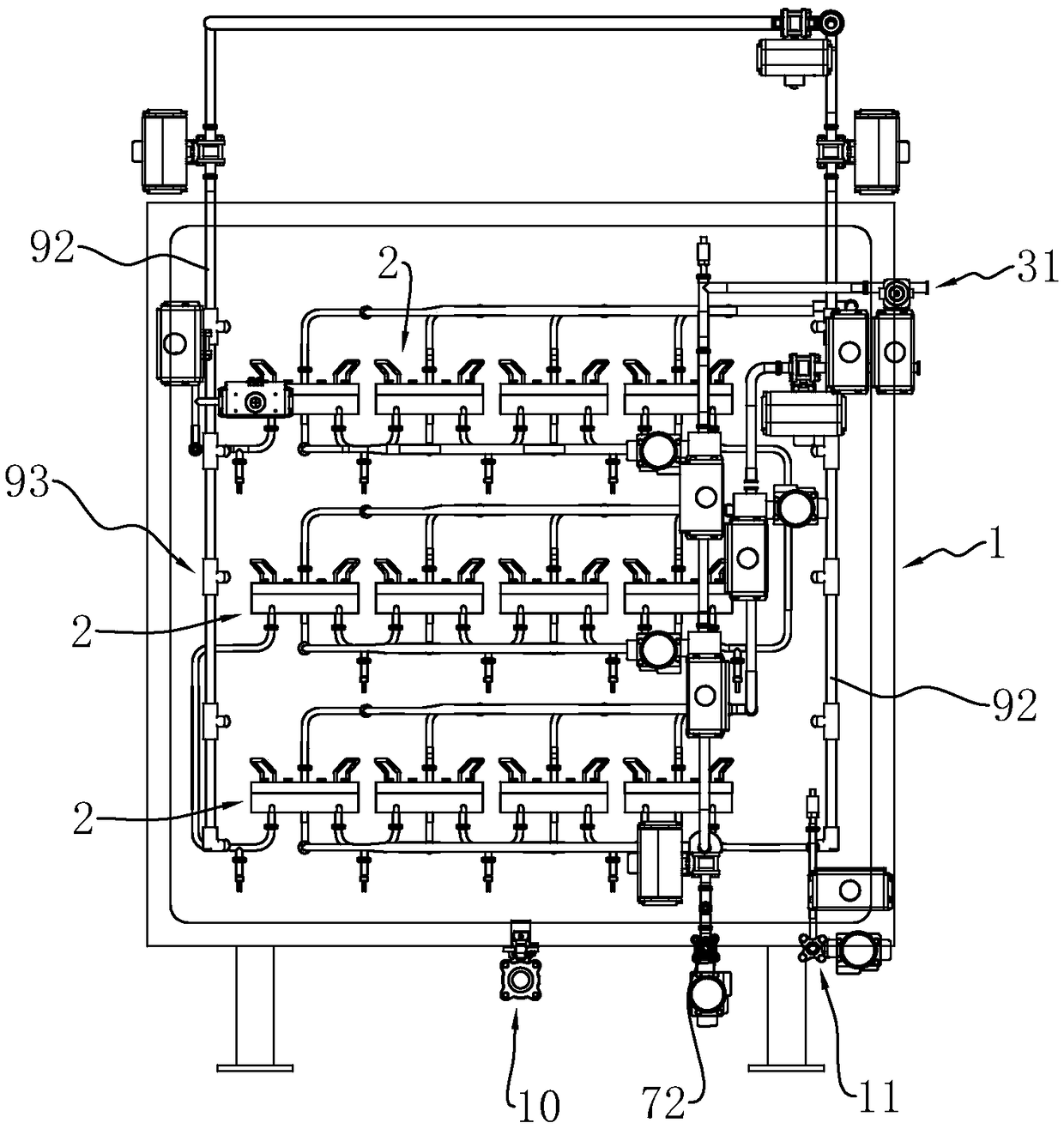

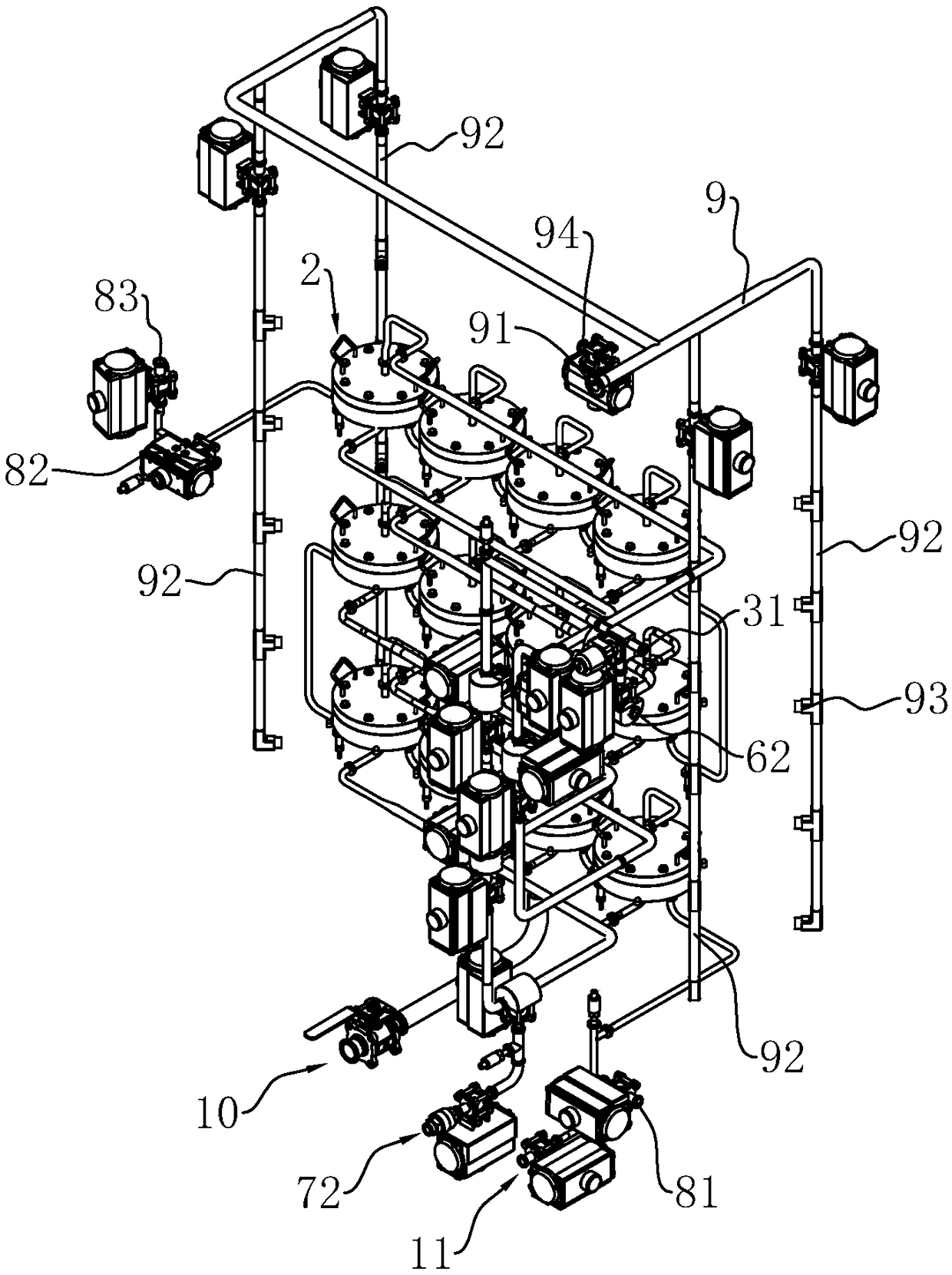

[0043] See attached Figure 2-3, a liquid medicine extrusion machine, comprising a cabinet 1, a number of extrusion instruments 2 are fixed in the cabinet 1; in one embodiment, the extrusion instruments 2 are provided with 12, and every four extrusion instruments 2 constitute a Extrusion modules, each extrusion module is neatly arranged in three rows in the chassis 1. At the same time, the liquid medicine extruder also includes a cleaning system for cleaning each extruder 2, and the cleaning system includes a first cleaning assembly, a second cleaning assembly, and a third cleaning assembly; wherein, the first cleaning assembly is mainly used for The inside of the extruder 2 is cleaned and sterilized, the second cleaning component is mainly used for cleaning the jacket 29 , and the third cleaning component is mainly used for cleaning the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com