Hollow spindle device for powder concentrator

A hollow main shaft and main shaft device technology, applied in the directions of shafts, couplings, shafts and bearings, can solve the problems of inconvenient main shaft transportation, installation and maintenance, adverse effects of powder separator equipment, and easy swinging of main shaft cage wheels. Achieve the effect of increasing disassembly performance, reducing machining workload, and reducing steel investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment and accompanying drawing, the utility model is further described.

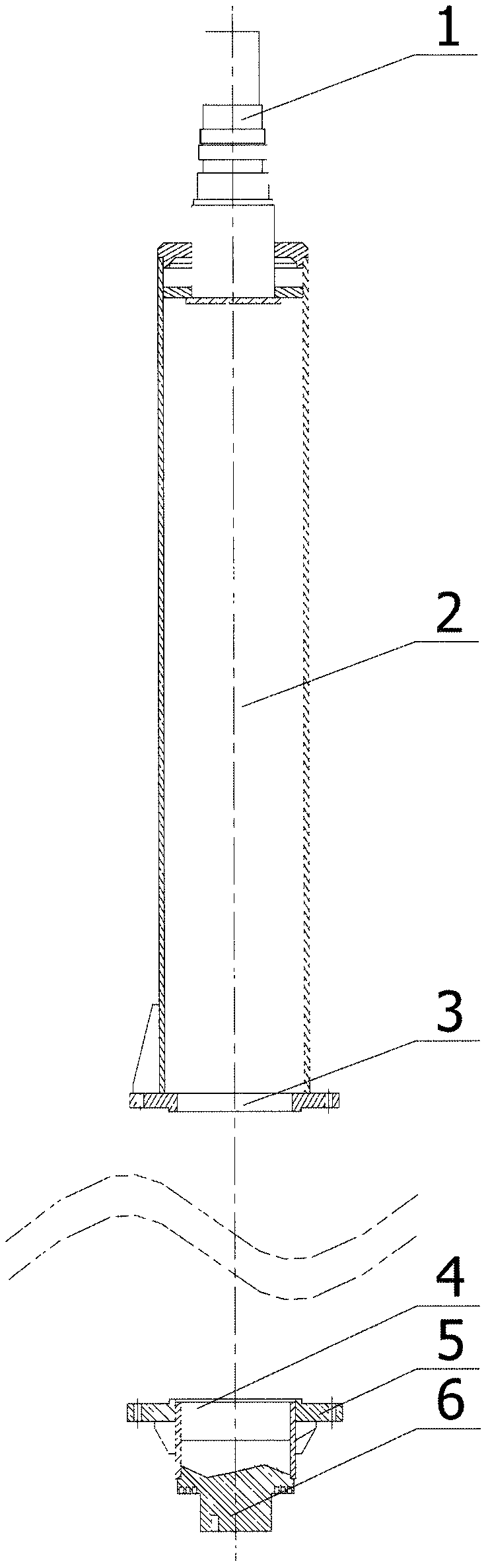

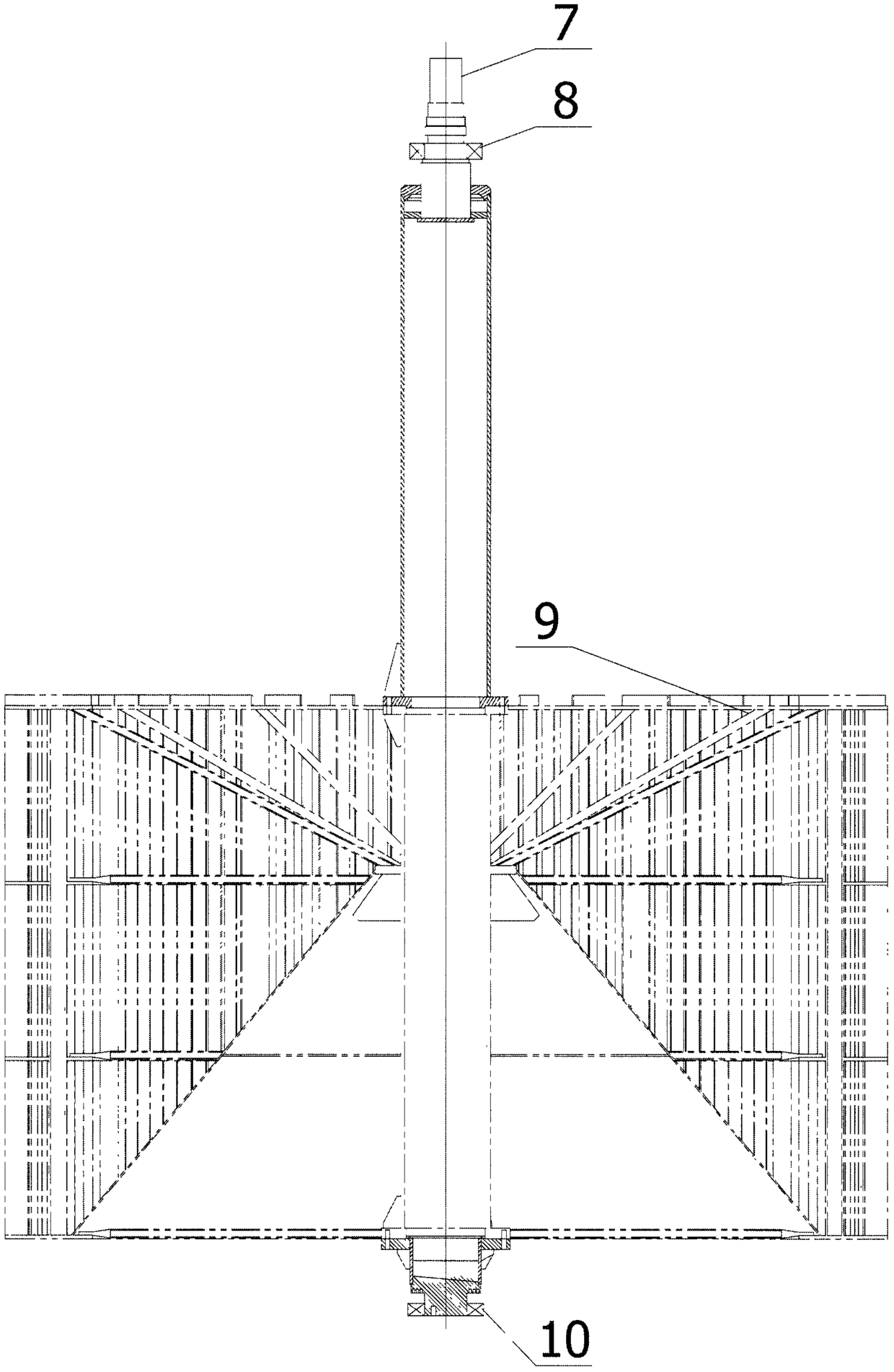

[0019] Such as Figures 1 to 2 As shown, a hollow spindle device used in a powder classifier, including shaft (1) 1, shaft (2) 6, seamless steel pipe for structure (1) 2, seamless steel pipe for structure (2) 4, flange (1) 3, flange (2) 5, the main part of the main shaft is a hollow structure, the shaft (1) 1, flange (1) 3 are fixed on the structural seamless steel pipe (1) 2 by welding, forming the main shaft the upper part of the . Axle (two) 6 and flange (two) 5 are fixed on the structural seamless steel pipe (two) 4 by welding, forming the lower half of the main shaft. The cage wheel is installed between the upper half and the lower half of the main shaft, and the cage wheel is fixed by the connecting bolts of flange (1) 3, flange (2) 5 and the matching flange on the cage wheel, thus forming a complete set of spindle device.

[0020] Work process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com