Highly-conductive flexible graphene tube and preparation method thereof

A technology of flexible graphite and graphene tubes, applied in the direction of graphene, nano-carbon, etc., can solve the problems of mechanical and conductive properties limiting the application of graphene tubes, low fiber conductivity, and easy damage of the structure, to achieve increased specific surface area, Effect of increasing specific surface area and stabilizing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

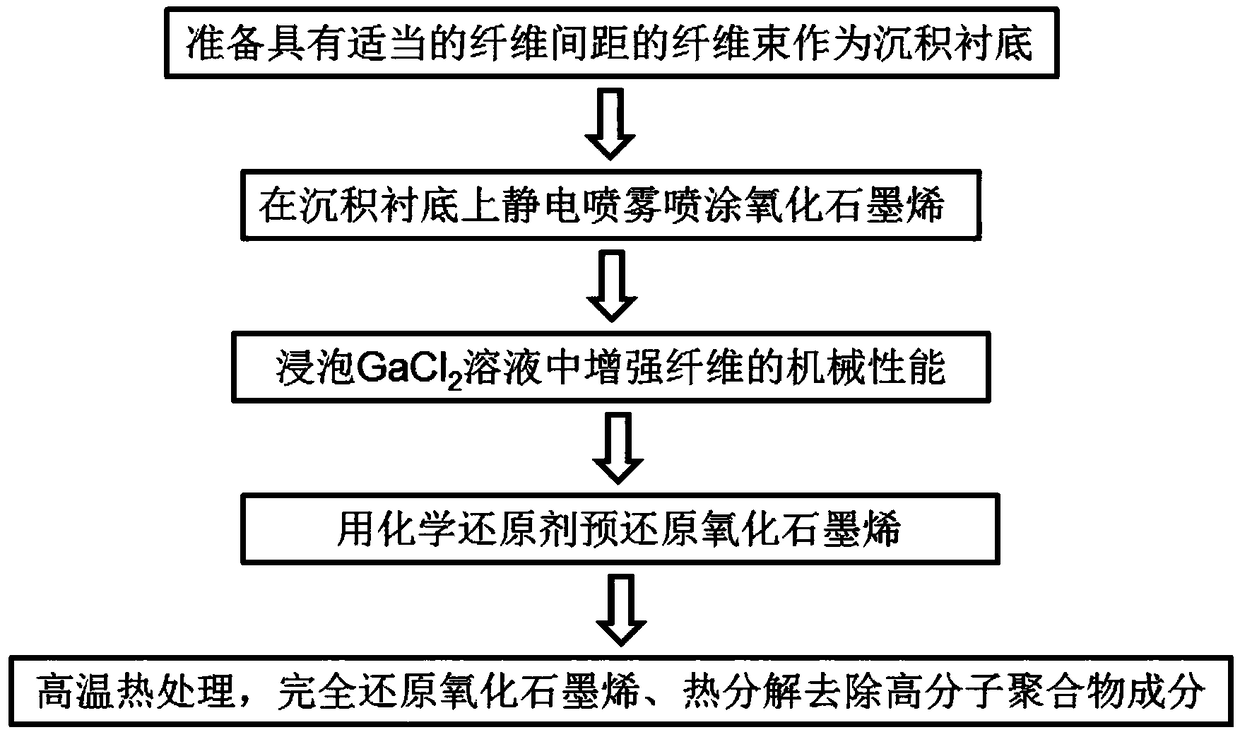

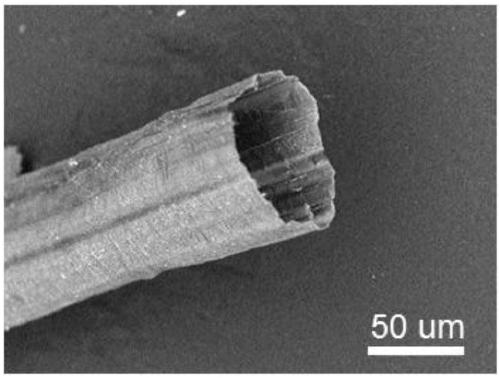

[0043] like figure 1 Shown in the flowchart of, a kind of preparation method of highly conductive flexible graphene tube comprises the following steps:

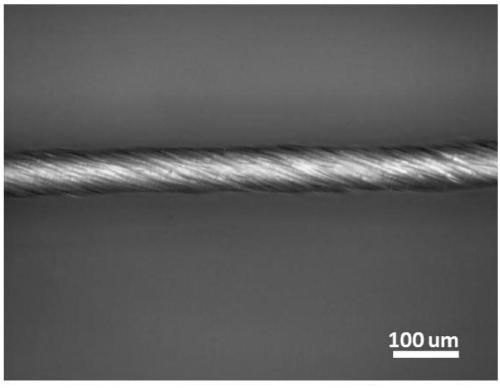

[0044] (1) Prepare the deposition substrate: Twist the polyester fiber bundles until the gap between the fibers is less than 0.4 μm to form a tightly twisted stranded fiber bundle (such as figure 2 shown), as a deposition substrate;

[0045] (2) Electrostatic spraying of graphene oxide: the graphene oxide dispersion is placed in the liquid storage mechanism of the electrostatic spraying device, and the deposition substrate obtained in step (1) is sprayed with graphene oxide with the electrostatic spraying device, and the electrostatic spraying parameter is spray The voltage is 8kV, the spray distance is 3cm, the propulsion rate of the liquid propulsion part of the liquid storage mechanism of the electrostatic spray device to the graphene dispersion is 12ul / min, and the electrostatic spray time is 60min, and the graphene oxi...

Embodiment 2

[0051] like figure 1 Shown in the flowchart of, a kind of preparation method of highly conductive flexible graphene tube comprises the following steps:

[0052] (1) Prepare the deposition substrate: adjust the polyester fiber bundle to a loose fiber bundle with three fiber gaps between 0.4 μm and 2 μm (such as Image 6 shown), as a deposition substrate;

[0053] (2) Electrostatic spraying of graphene oxide: the graphene oxide dispersion is placed in the liquid storage mechanism of the electrostatic spraying device, and the deposition substrate obtained in step (1) is sprayed with graphene oxide with the electrostatic spraying device, and the electrostatic spraying parameter is spray The voltage is 8kV, the spray distance is 3cm, the propulsion rate of the liquid propulsion part of the liquid storage mechanism of the electrostatic spray device to the graphene dispersion is 12ul / min, and the electrostatic spray time is 60min, and the graphene oxide / polymer composite fiber is ob...

Embodiment 3

[0059] like figure 1 Shown in the flowchart of, a kind of preparation method of highly conductive flexible graphene tube comprises the following steps:

[0060] (1) Prepare the deposition substrate: adjust the nylon fiber bundle to a loose fiber bundle with multiple fiber gaps between 0.4 μm and 2 μm (such as Figure 8 shown), as a deposition substrate;

[0061] (2) Electrostatic spraying of graphene oxide: the graphene oxide dispersion is placed in the liquid storage mechanism of the electrostatic spraying device, and the deposition substrate obtained in step (1) is sprayed with graphene oxide with the electrostatic spraying device, and the electrostatic spraying parameter is spray The voltage is 15kV, the spray distance is 10cm, the propulsion rate of the liquid propulsion part of the liquid storage mechanism of the electrostatic spray device to the graphene dispersion is 3μl / min, and the electrostatic spray time is 40min, and the graphene oxide / polymer composite fiber is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com