Coal mine underground sewage water quality softening reuse process treatment system

A water softening and treatment system technology, applied in the field of coal mines, can solve the problems of waste of water treatment resources, high operating costs, and inability to achieve centralized management of sewage treatment, etc., to achieve the effect of protecting the normal service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

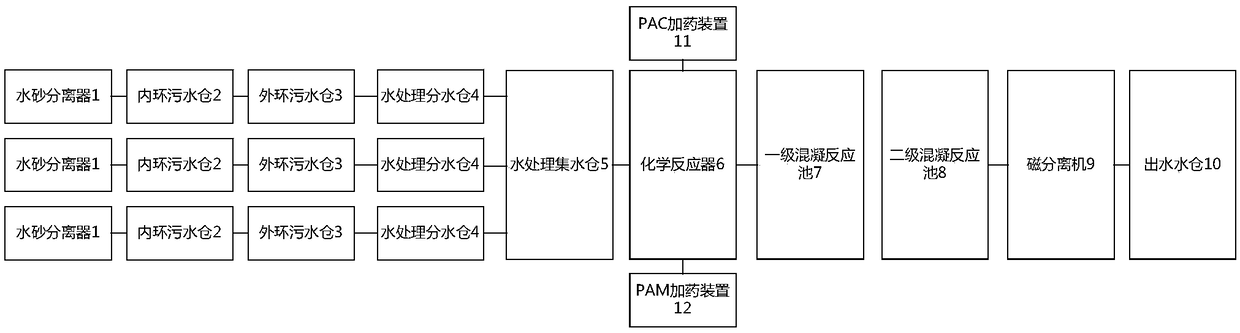

[0106] The invention provides a treatment system for the softening and reuse process of underground sewage in coal mines, such as Figures 1 to 8 As shown, including: multiple mining areas and water treatment areas;

[0107] There is a sewage treatment chamber in the mining area, and the sewage treatment chamber is equipped with a water and sand separator 1, an inner ring sewage tank 2 and an outer ring sewage tank 3;

[0108] Mine gushing water is discharged to the water-sand separator 1, separated by the water-sand separator 1, and then sent to the inner ring sewage tank 2, and the mine water is sent to the outer ring sewage tank 3 after passing through the inner ring sewage tank 2;

[0109] Here, the outer ring sewage tank 3 and the inner ring sewage tank 2 can use the mine water separated by the water-sand separator 1 to be transported to the inner ring sewage tank 2, and then the mine water can be transported to the water-sand separator after passing through the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com