A method and apparatus for producing water from air by utilizing a hydrophilic-hydrophobic bonding structure

A hydrophilic, hydrophobic, air technology, applied in drinking water installations, water supply installations, buildings, etc., can solve the problems of reducing cooling energy transfer, increasing additional energy consumption, wasting cooling energy, etc., achieving good heat exchange performance and low condensation thermal resistance. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The accompanying drawings disclose a preferred embodiment of the present invention without limitation, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

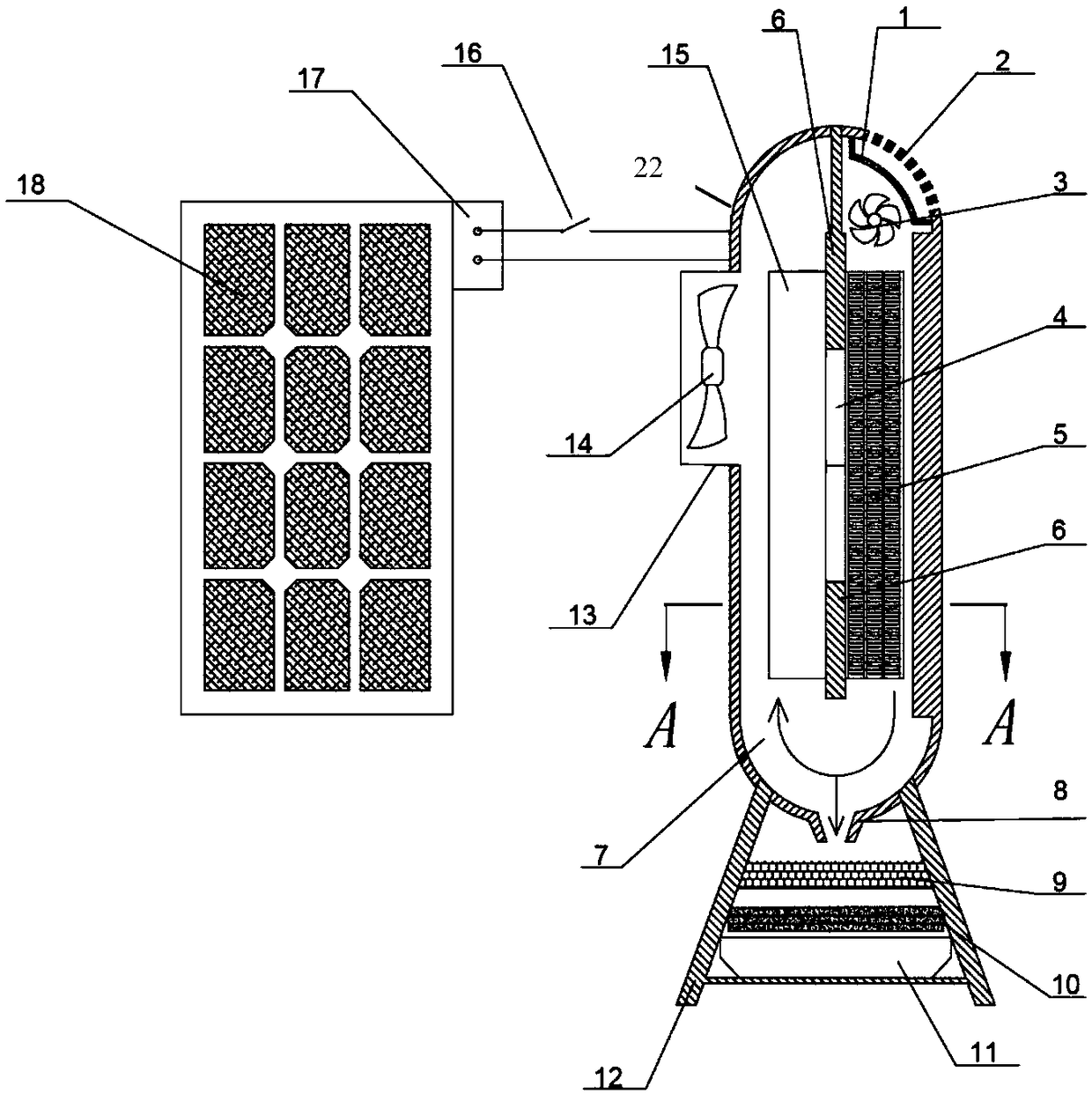

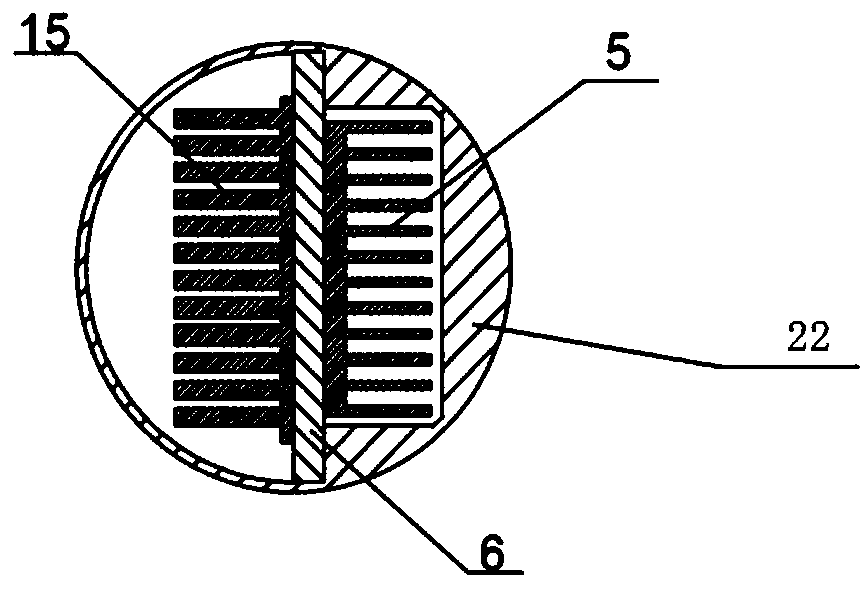

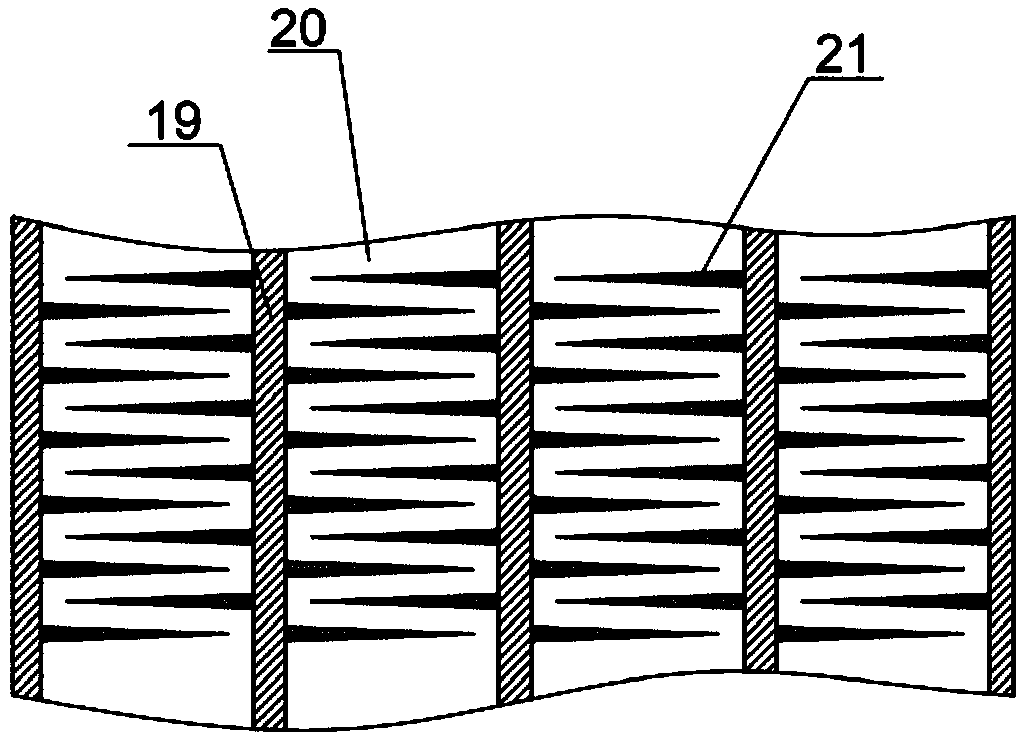

[0036] Such as figure 1 and figure 2As shown, the present invention utilizes the device of hydrophilic-hydrophobic combination structure to make water from the air, and comprises that the cross section that is arranged on the support 12 is oval shell 22, and the inner top of shell 22 is provided with substrate 6, and base plate 6 is arranged on shell 22 The cavity is divided into a cold zone flow channel and a hot zone flow channel, and the cold zone flow channel and the hot zone flow channel are connected through the diversion channel 7 . The substrate 6 is provided with a semiconductor cooling fin 4, the cooling fin 5 is arranged in the flow channel of the cold zone, and the heat dissipation fin 15 is arranged in the hot zone flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com