Wind turbine blade polypyrrole nanometer coating anti-icing technical method

A wind turbine blade and polypyrrole nanotechnology, which is applied in wind turbines, motors, wind power generation and other directions, can solve the problems of successful research and development of wind turbine blade coating anti-icing technology, and achieve novel technical methods, good sealing performance, and anti-caking. good ice effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

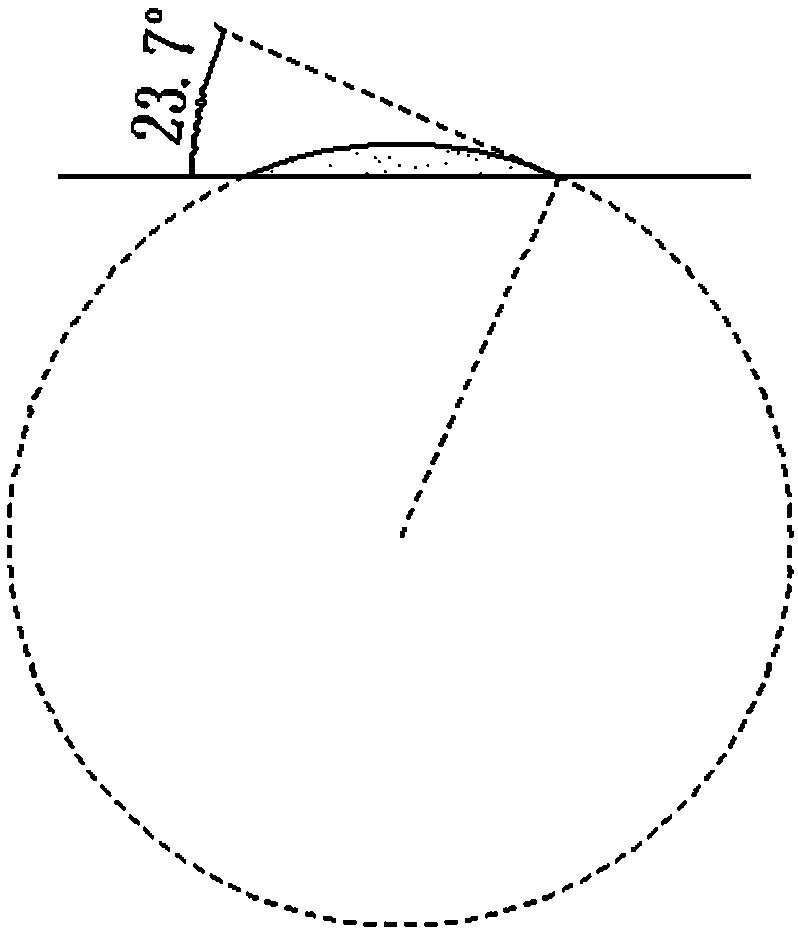

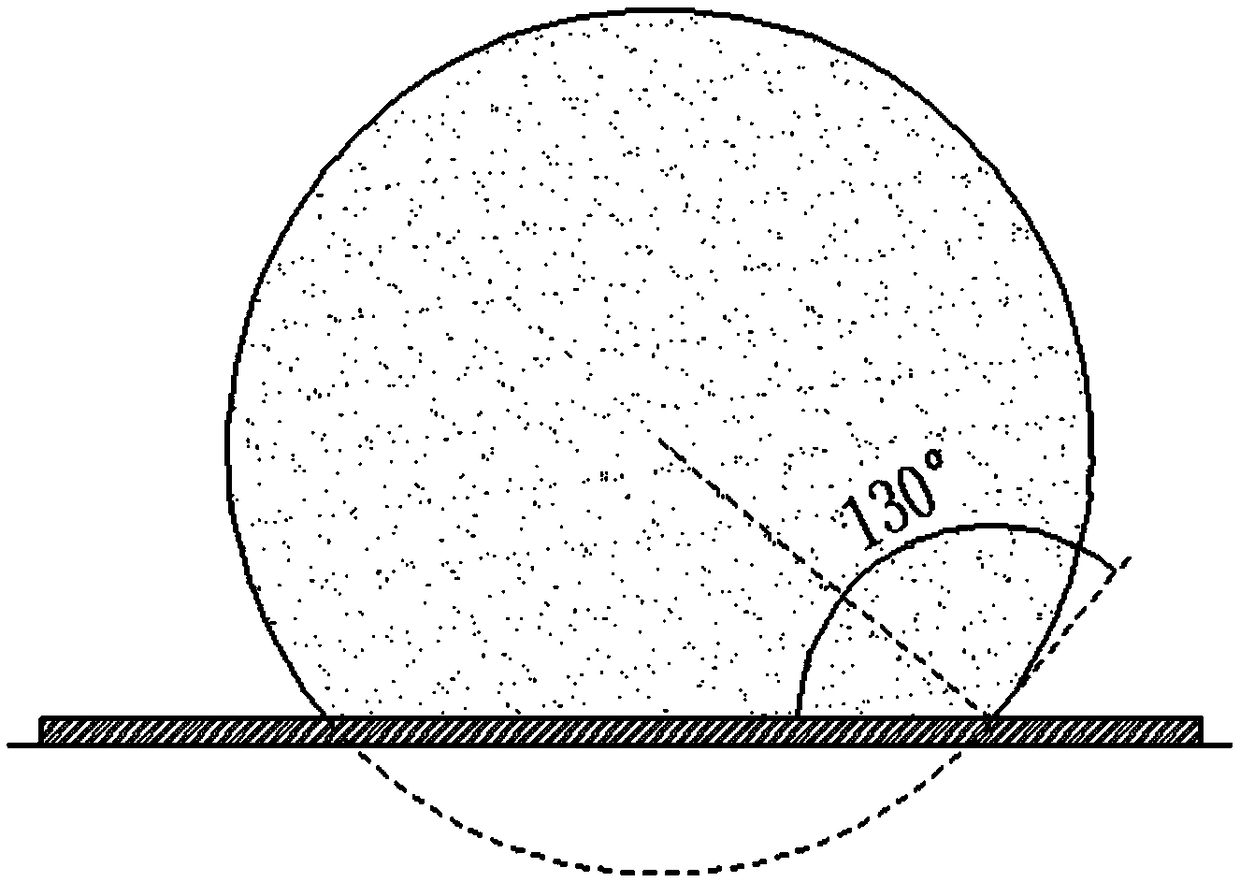

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A technical method for anti-icing technology of polypyrrole nano-coating for wind turbine blades, coating the surface of wind turbine blade shell with hydrophobic polypyrrole nano-coating, the specific technical method is: conducting 1.5-2.5 hours of nanoscale polypyrrole powder After ball milling until bright black luster is produced, the polypyrrole powder with bright black luster after ball milling and the binder polyvinylidene fluoride with a concentration of 6-8%, the purity of analytically pure solvent N-methylpyrrolidone and Anhydrous ethanol is mixed in a mass ratio of 8:1:32:16, and a black viscous liquid is obtained after ultrasonic stirring, and the black viscous liquid is evenly coated on the surface of the wind turbine blade shell made of glass fiber reinforced plastic, and the wind turbine blade is placed Put it into a drying oven and dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com