A method for preparing a lithium metal electrode

A lithium metal electrode and non-polar solvent technology, applied in the field of lithium metal electrode preparation, can solve problems such as battery short circuit, achieve good conductivity, avoid excessive local current, good cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

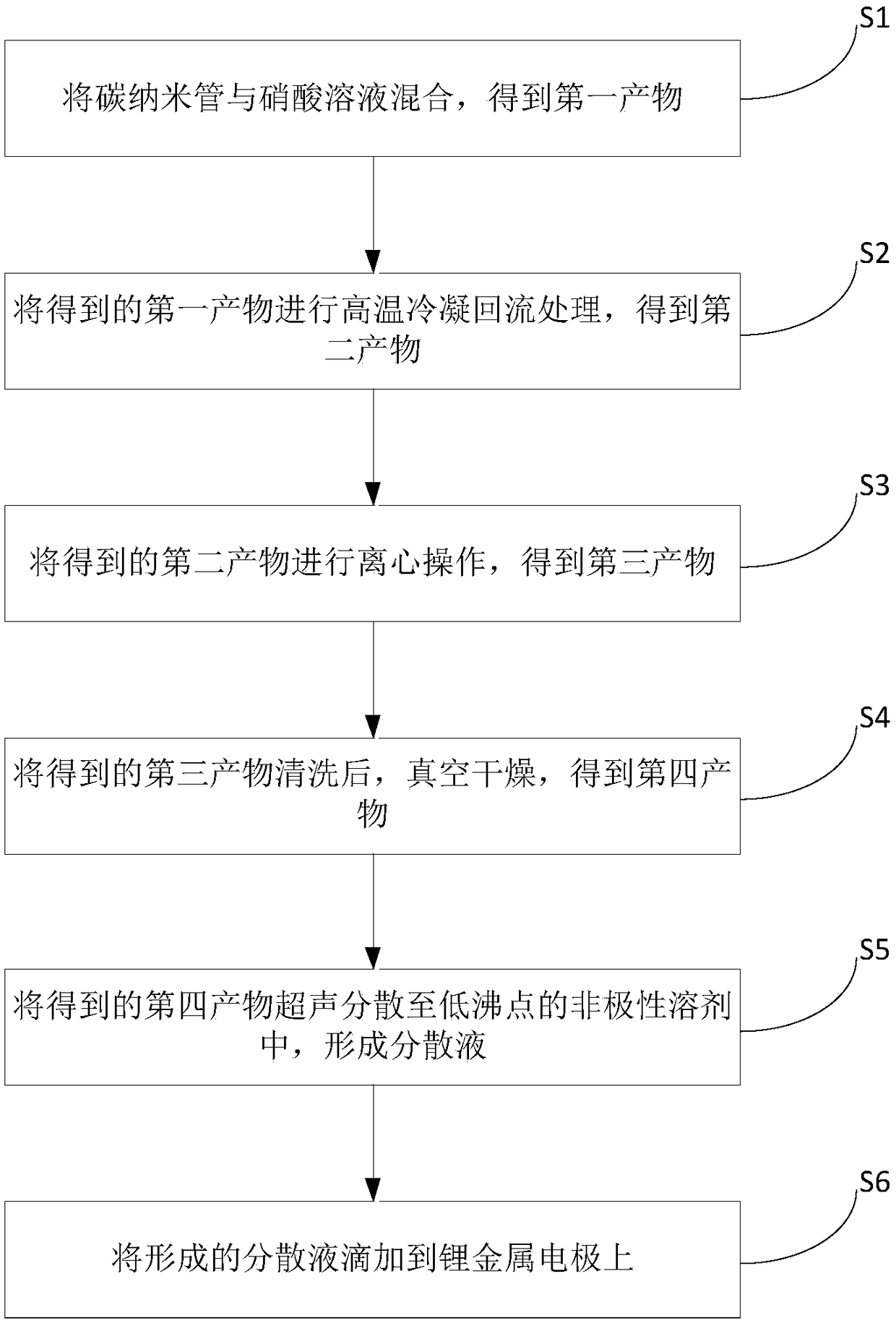

[0038] figure 1 It is a schematic flow diagram of a preparation method of a lithium metal electrode according to an embodiment of the present invention, see figure 1 , the method includes:

[0039] S1: mixing carbon nanotubes with nitric acid solution to obtain the first product;

[0040] S2: subjecting the obtained first product to high-temperature condensation and reflux treatment to obtain a second product;

[0041] S3: centrifuging the obtained second product to obtain a third product;

[0042] S4: After washing the obtained third product, vacuum drying is obtained to obtain a fourth product;

[0043] S5: ultrasonically dispersing the obtained fourth product into a low-boiling non-polar solvent to form a dispersion;

[0044] S6: adding the formed dispersion liquid onto the lithium metal electrode dropwise;

[0045] S7: After the dispersion liquid is naturally and evenly spread on the lithium metal electrode, the lithium metal electrode with the dispersion liquid is ev...

Embodiment 1

[0064] (1) 0.5 gram of multi-walled carbon nanotubes is mixed with 150 milliliters of 3M nitric acid solution to obtain the first product;

[0065] (2) subjecting the first product to reflux at 150° C. for 4 hours to obtain the second product;

[0066] (3) centrifuging the second product to obtain a third product;

[0067] (4) washing the third product with deionized water and ethanol five times, and drying in vacuum at 80° C. to obtain the fourth product, i.e. acidified carbon nanotubes after drying;

[0068] (5) ultrasonically disperse the fourth product in tetrahydrofuran at 1 mg / mL to form a dispersion;

[0069] (4) The dispersion liquid is directly dropped onto the lithium metal electrode in an amount of 60 microliters per square centimeter, the dispersion liquid is naturally and evenly spread, and the solvent is evaporated to dryness at 40° C. to obtain a lithium metal electrode 1 with a modified layer on the surface. .

Embodiment 2

[0071] (1) 0.5 gram of multi-walled carbon nanotubes is mixed with 150 milliliters of 3M nitric acid solution to form the first product;

[0072] (2) subjecting the first product to reflux at 150° C. for 4 hours to obtain the second product;

[0073] (3) centrifuging the second product to obtain a third product;

[0074] (4) washing the third product with deionized water and ethanol five times, and vacuum-drying at 80°C to obtain the fourth product, i.e. acidified carbon nanotubes after drying;

[0075] (5) ultrasonically disperse the fourth product in tetrahydrofuran at 2 mg / mL to form a dispersion;

[0076] (6) The dispersion liquid is directly dropped onto the lithium metal electrode in an amount of 60 microliters per square centimeter, the dispersion liquid is naturally and evenly spread, and the solvent is evaporated to dryness at 40°C to obtain a lithium metal electrode 2 with a modified layer on the surface. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com