A wideband low profile microstrip antenna

A microstrip antenna and low profile technology, applied in the field of wireless communication systems and broadband low profile microstrip antennas, can solve problems such as narrow bandwidth and limitations, and achieve the effects of widening bandwidth, reducing quality factor, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

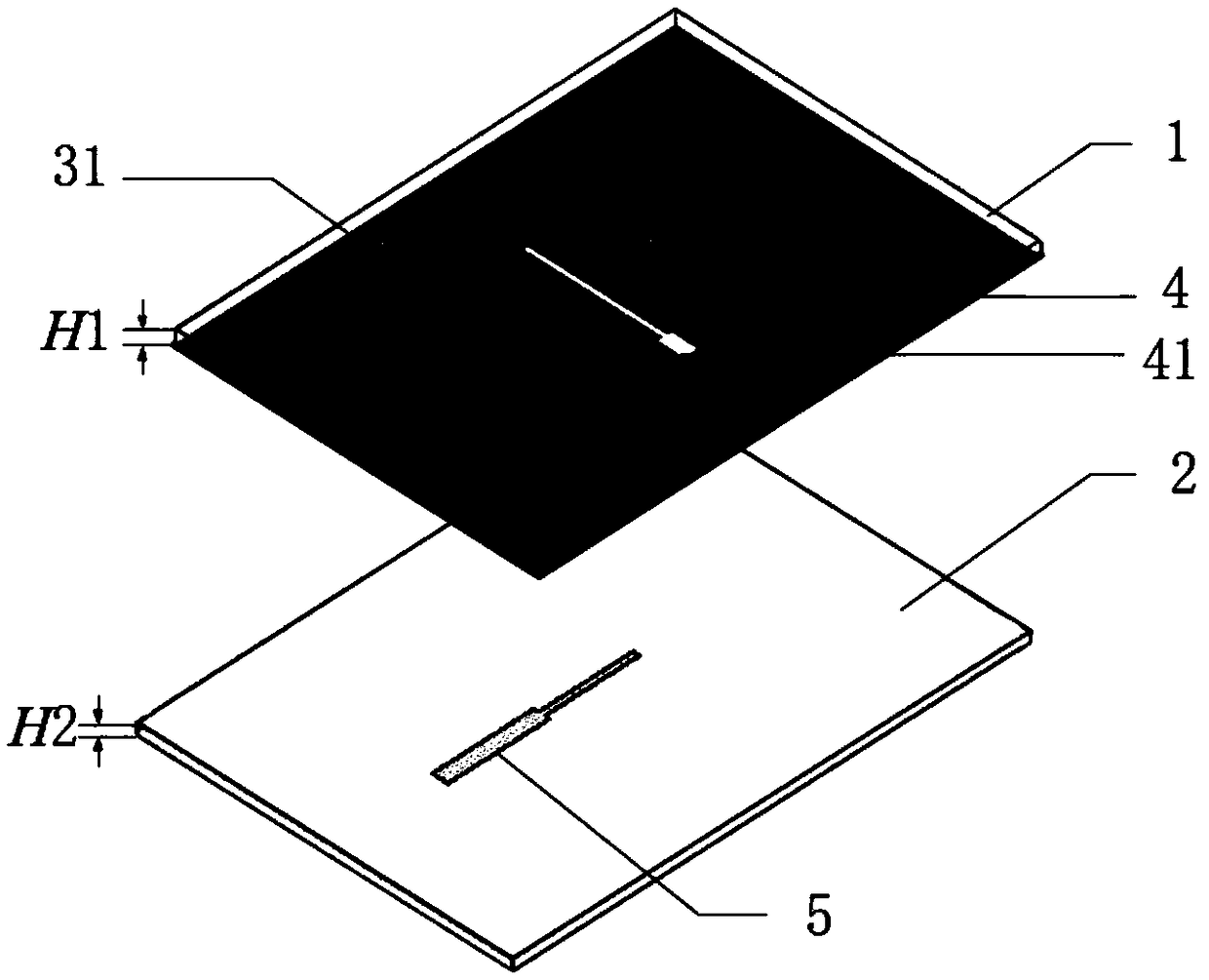

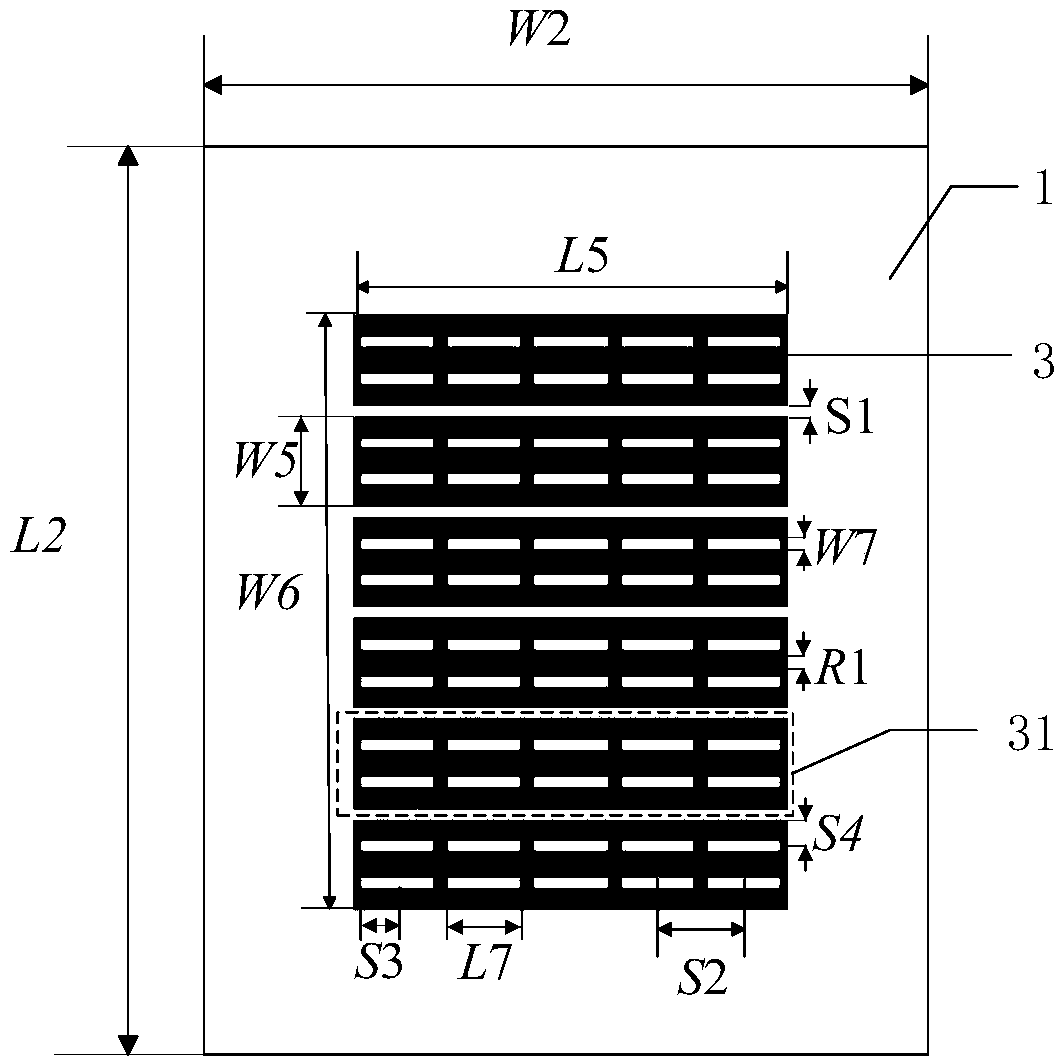

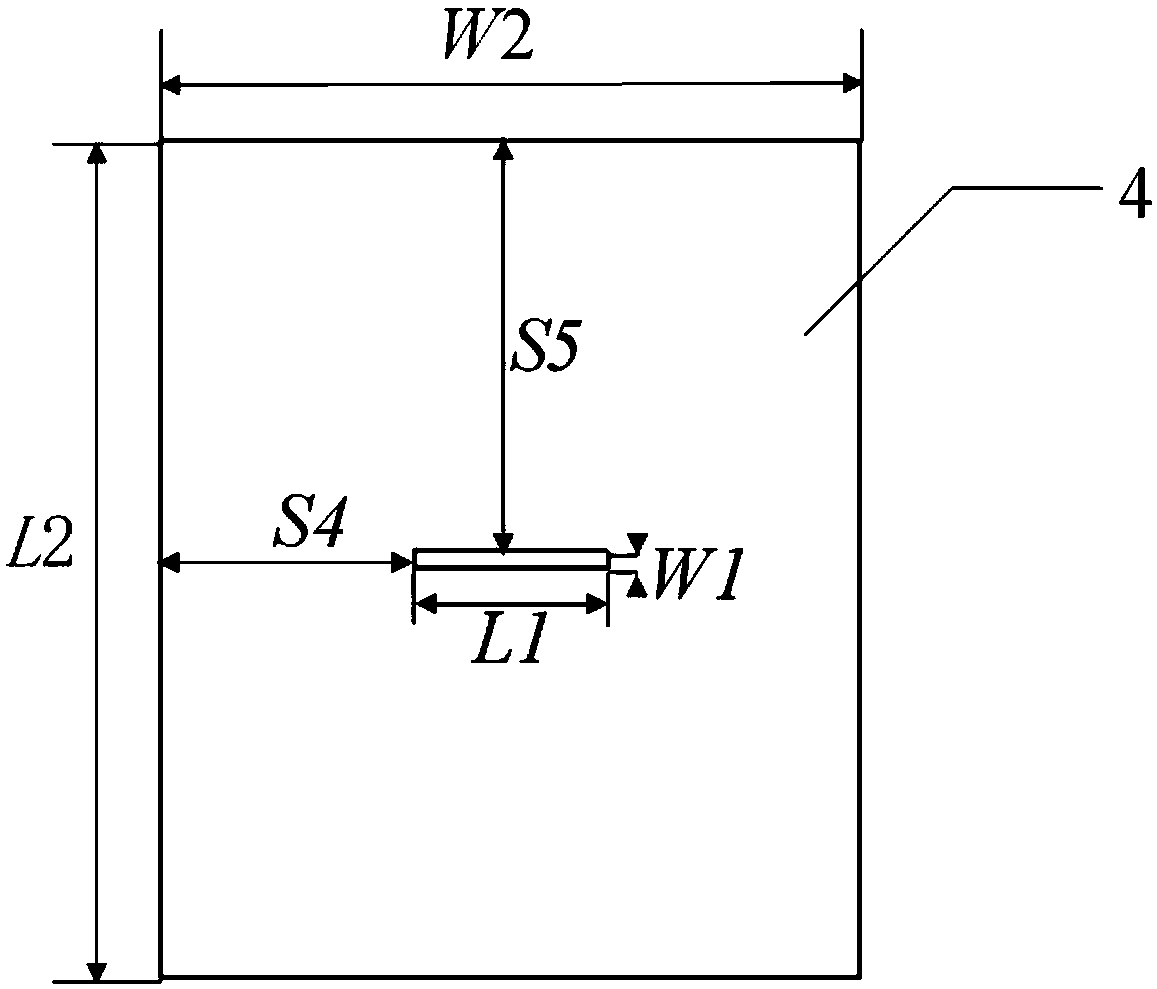

[0025] refer to figure 1 , a broadband low-profile microstrip antenna, including a first dielectric substrate 1 and a second dielectric substrate 2 stacked up and down, the thickness of the first dielectric substrate 1 is H1=0.508mm, and the dielectric constant ε 1 =3.48, the thickness H2 of the second dielectric substrate 2=0.254mm, the dielectric constant ε 2 =3.48; the upper surface of the first dielectric substrate 1 is printed with a radiation unit 3, and its structure is as follows figure 2 As shown, a metal floor 4 is printed on the lower surface, and a first rectangular slit 41 is etched on the metal floor 4, and its structure is as follows image 3 As shown; the lower surface of the second dielectric substrate 2 is printed with a microstrip feeder 5, and its structure is as follows Figure 4 Shown; the profile height of the antenna is 0.762mm.

[0026] refer to figure 2 , the plate surface shape of the first dielectric substrate 1 is rectangular, its wide side d...

Embodiment 2

[0033] This embodiment has the same structure as Embodiment 1, only some parameters have been adjusted;

[0034] The number of rectangular patches 31 is N=3, the distance between adjacent rectangular patches 31 is S1=0.1mm, and the number of second rectangular slits in each row is M=3;

[0035] The wide side of the first rectangular slit 41 is W1=0.3mm, and the long side L1=4mm;

[0036] The wide side of the first dielectric substrate 1 is W2=17mm, the long side is L2=22mm, the thickness is H1=0.4mm, and the dielectric constant ε 1 =2, the thickness H2 of the second dielectric substrate 2=0.2mm, the dielectric constant ε 2 = 2;

[0037] The wide side of the first microstrip line 51 is W3=0.4mm, the long side L3=2.8mm, the wide side W4=0.16mm of the second microstrip line 52, and the long side L4=2.5mm.

Embodiment 3

[0039] This embodiment has the same structure as Embodiment 1, only some parameters have been adjusted;

[0040] The number of rectangular patches 31 is N=8, the distance between adjacent rectangular patches 31 is S1=0.3mm, and the number of second rectangular slits in each row is M=8;

[0041] The wide side of the first rectangular slit 41 is W1=0.6mm, and the long side L1=6mm;

[0042] The wide side of the first dielectric substrate 1 is W2=23mm, the long side is L2=26mm, the thickness is H1=0.6mm, and the dielectric constant ε 1 =6, the thickness H2 of the second dielectric substrate 2=0.3mm, the dielectric constant ε 2 = 6;

[0043] The wide side of the first microstrip line 51 is W3=0.6mm, the long side L3=3.5mm, the wide side W4=0.3mm of the second microstrip line 52, and the long side L4=3.2mm.

[0044] Below in conjunction with simulation experiment, technical effect of the present invention is described further:

[0045] 1. Simulation conditions and content:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com