Full-automatic fruit picking device

A fully automatic, fruit technology, applied in picking machines, agricultural machinery and implements, applications, etc., can solve the problems of inability to ensure picking quality, inability to adapt to picking operations, low picking efficiency, etc., to ensure picking quality, ingenious design, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

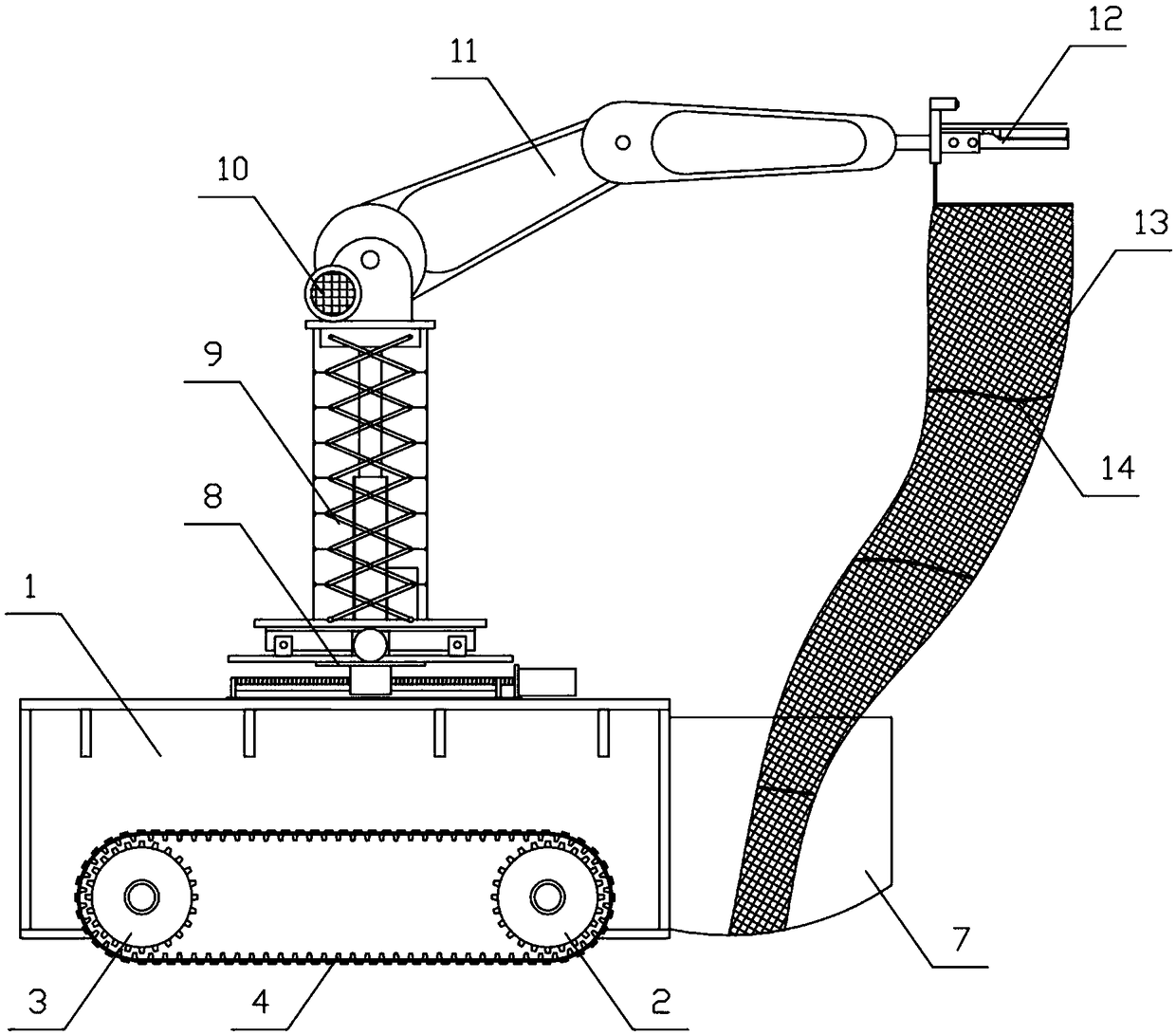

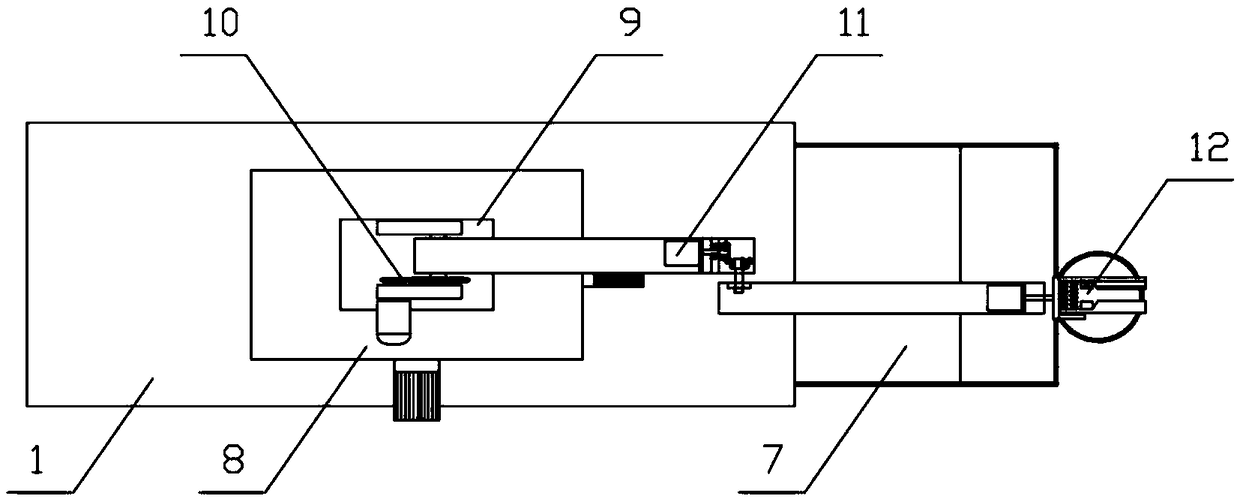

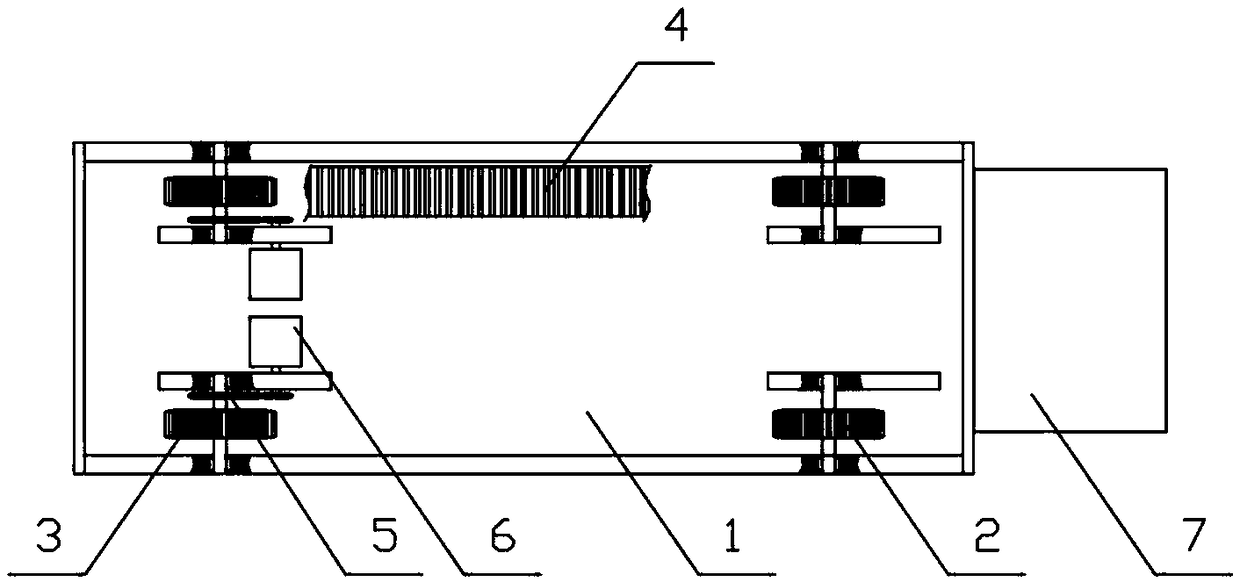

[0045] Such as Figure 1-10 As shown, the present invention provides a kind of fully automatic fruit picking device, has crawler vehicle, is provided with the fruit box 7 of upper opening and control device on crawler vehicle, is also provided with mobile base frame on crawler vehicle, mobile base frame has XY Axis mobile platform 8, telescopic support frame 9 is vertically equipped with on the XY axis mobile platform 8; One end is equipped with a shearing operator 12; the shearing operator 12 has a base 121, and the upper, middle and lower parts of the base 121 are correspondingly equipped with a horizontally arranged binocular camera 122, a shearing tool and a suspension ring 123, Hanging ring 123 connects the upper port of soft bag 13, and the lower port of soft bag 13 stretches in the fruit box 7, and is provided with several layers of anti-collision skirts 14 in soft bag 13.

[0046] The control device is composed of an upper main controller 15, a lower walking controlle...

Embodiment 2

[0054] This embodiment is based on the control method of a fully automatic fruit picking device described in Embodiment 1, comprising the following steps:

[0055] (1) System equipment initialization;

[0056] (2) The main controller controls the binocular camera to perform shooting operations to obtain the current road surface image information, and obtains the current DGPS position coordinates and heading information of the tracked vehicle through the configured GPS monitoring receiver. The main controller uses the built-in visual navigation image The processing algorithm processes the information to extract the visual navigation parameters and realize the navigation control of the tracked vehicle;

[0057] (3) The main controller controls the binocular camera to perform shooting operations to obtain the current image information of the fruit tree. The main controller processes the image information of the fruit tree through a built-in algorithm to realize the identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com