Preparation method of cookies rich in anthocyanin flavor

An anthocyanin and flavor technology, applied in the field of cookie processing, to achieve the effect of broad market space, novel colors and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

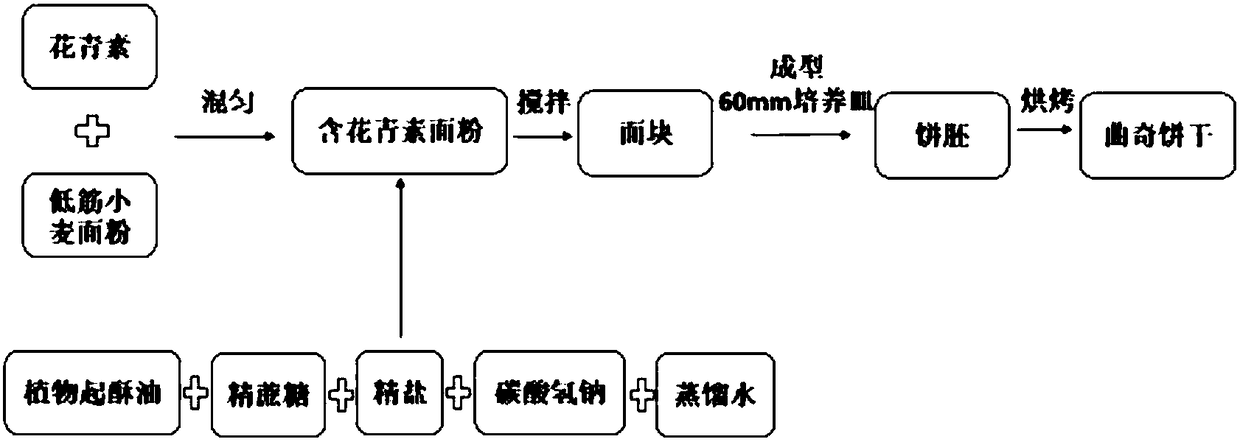

Image

Examples

Embodiment 1

[0021] (1) Accurately weigh 8-10g of commercially available low-gluten wheat flour, mix 0.05% anthocyanin powder therein, and mix evenly;

[0022] (2) Weigh a certain amount of commercially available vegetable shortening (3-4g), refined sucrose (4.0-4.2g), refined salt (0.070-0.075g), sodium bicarbonate (0.1-0.2g), distilled water (200-230μL ), added in the flour in turn;

[0023] (3) Mix the above-mentioned materials together, and use uniform strength to manually stir for 6-8 minutes at room temperature;

[0024] (4) In order to prevent the dough from becoming hard and unable to operate, after the powder is adjusted, it does not need to stand still and press the surface, and directly enters the molding process. In order to ensure the same size, the dough is pressed into a 0.8-1.5 cm thick uniform cake embryo;

[0025] (5) Put the formed cake embryo into an oven and bake at a temperature of 150-180° C. for 10-15 minutes, and cool to room temperature.

Embodiment 2

[0027] (1) Accurately weigh 8-10g of commercially available low-gluten wheat flour, mix 0.1% anthocyanin powder therein, and mix evenly;

[0028] (2) Weigh a certain amount of commercially available vegetable shortening (3-4g), refined sucrose (4.0-4.2g), refined salt (0.070-0.075g), sodium bicarbonate (0.1-0.2g), distilled water (200-230μL ), added in the flour in turn;

[0029] (3) Mix the above-mentioned materials together, and use uniform strength to manually stir for 6-8 minutes at room temperature;

[0030] (4) In order to prevent the dough from becoming hard and unable to operate, after the powder is adjusted, it does not need to stand still and press the surface, and directly enters the molding process. In order to ensure the same size, the dough is pressed into a 0.8-1.5 cm thick uniform cake embryo;

[0031] (5) Put the formed cake embryo into an oven and bake at a temperature of 150-180° C. for 10-15 minutes, and cool to room temperature.

Embodiment 3

[0033] (1) Accurately weigh 8-10g of commercially available low-gluten wheat flour, mix 0.2% anthocyanin powder therein, and mix evenly;

[0034] (2) Weigh a certain amount of commercially available vegetable shortening (3-4g), refined sucrose (4.0-4.2g), refined salt (0.070-0.075g), sodium bicarbonate (0.1-0.2g), distilled water (200-230μL ), added in the flour in turn;

[0035] (3) Mix the above-mentioned materials together, and use uniform strength to manually stir for 6-8 minutes at room temperature;

[0036] (4) In order to prevent the dough from becoming hard and unable to operate, after the powder is adjusted, it does not need to stand still and press the surface, and directly enters the molding process. In order to ensure the same size, the dough is pressed into a 0.8-1.5 cm thick uniform cake embryo;

[0037] (5) Put the formed cake embryo into an oven and bake at a temperature of 150-180° C. for 10-15 minutes, and cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com