Preparation method of composite absorbent core and production device thereof

A technology for absorbing cores and production equipment, applied in absorbent pads, medical science, clothing, etc., which can solve the problems affecting the penetration rate, diffusion rate and utilization rate of cores, the drift and accumulation of polymer water-absorbent resins, and the formation of diversion grooves Difficult to control and other problems, to achieve the effect of ingenious structure of production equipment, improved diversion performance, and simple and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of composite absorbent core body A and its production equipment and preparation method

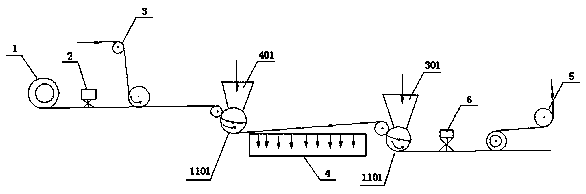

[0051] 1. Production equipment for a composite absorbent core

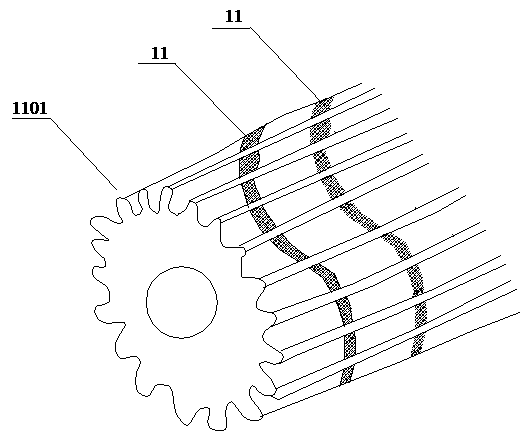

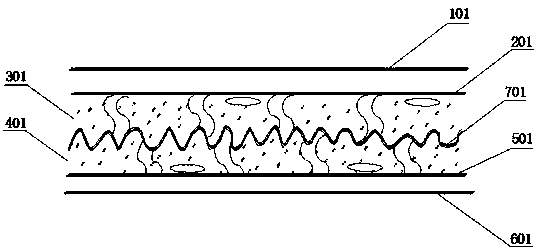

[0052] A kind of production equipment of composite absorbent core body of the present invention, as figure 1 As shown, it includes a conveying device and sequentially connected front glue spraying device 2, cloth guide roller 3, lower layer polymer injection device, negative pressure device 4, upper layer polymer injection device and rear glue spray device 6; the upper and lower layers are high The molecular injection device is the feeding roller 1101 . Such as figure 2 As shown, the outer wall of the unloading roller 1101 is provided with a plurality of grooves, and when the unloading roller 1101 rotates, the polymer water-absorbent resin is injected into the non-woven fabric through the grooves; There is also a filling area matching the diversion groove, and a filler 11 is provided in the filli...

Embodiment 2

[0071] The preparation of embodiment 2 composite core body B, C, D

[0072] The preparation method is basically the same as in Example 1, except that the mass ratios of 2-denier fibers, 4-denier fibers and 6-denier fibers in the fluffy non-woven fabric 701 in this example are 0.8:0.6:1.8, 0.5:1, respectively :2, 1:0.5:1.5, three different composite cores B, C, D were obtained respectively.

[0073] The composite core body A of the above-mentioned embodiment 1 and the composite core body B, C, and D in the embodiment 2 are subjected to a performance test, and the comparative test is a composite core body made of only 6 denier fibers according to the preparation process of the embodiment 1, The test method refers to GB / T28004-2011, and the absorption performance test results are shown in Table 1.

[0074] The absorption performance test result of the composite core body A in the embodiment 1 of table 1 and the composite core body B, C, D in the embodiment 2

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com