Automatic speed regulation and pressure control device and control method for extrusion machine

A technology of automatic speed regulation and extruder, which is used in metal extrusion control equipment, metal extrusion, manufacturing tools, etc. pressure efficiency and other issues, to achieve the effect of reducing management pressure and labor costs, high practicability, and strong product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: An automatic speed regulation and pressure control device for an extruder.

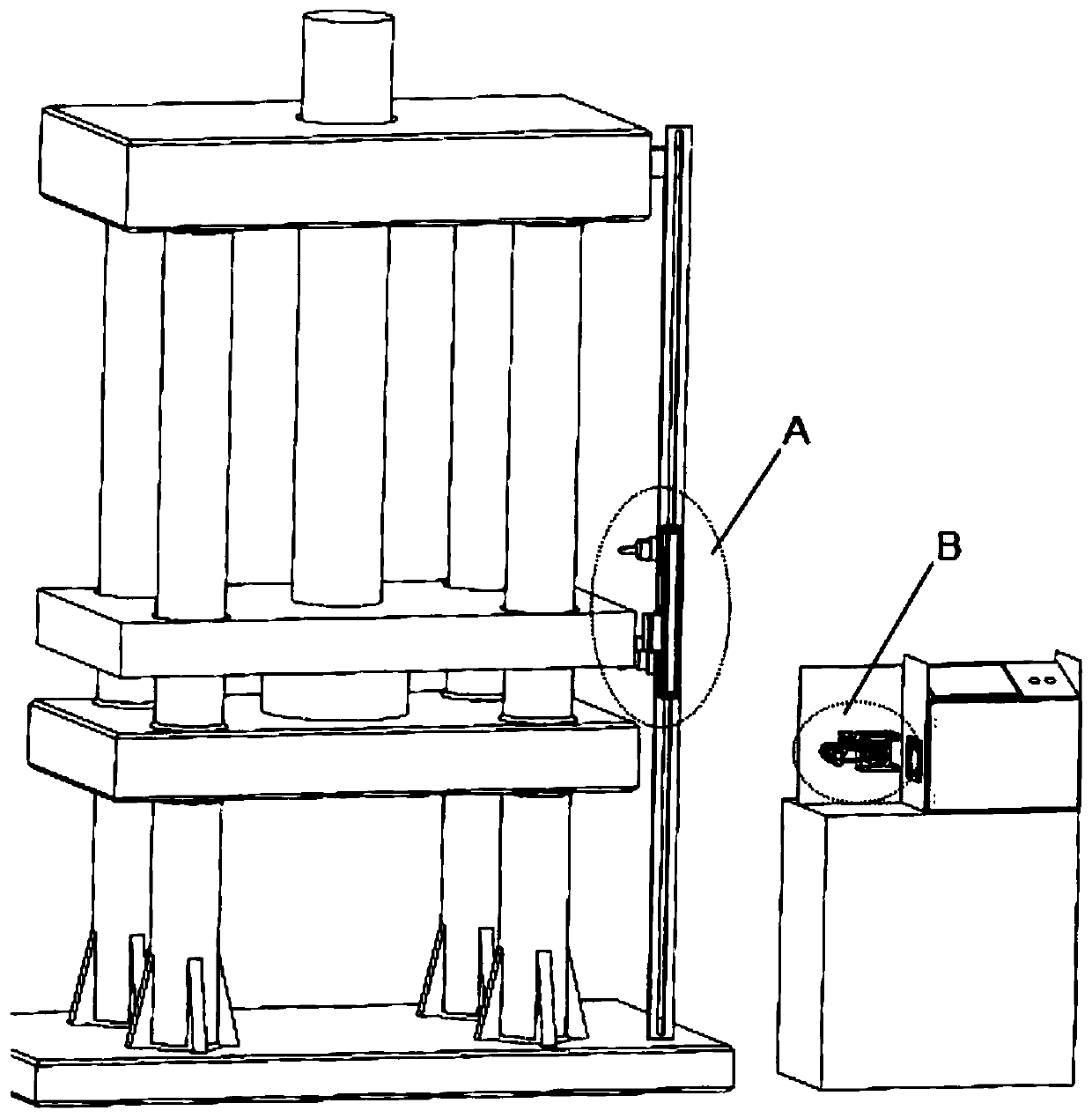

[0027] see figure 1 as shown, figure 1 For the use implementation scene diagram of the present invention, point out the installation position of each mechanism in this implementation scene:

[0028] A is the speed limit part placed on the main body of the extruder;

[0029] Part B is the pressure control and speed regulation part installed on the control seat of the extrusion machine. The right side of it is the PLC control cabinet in the control system. The microcomputer controller is installed in the PLC control cabinet. The microcomputer controller is connected with the brushless motor respectively. 6. The speed limit mechanism is electrically connected to the extruder speed limit mechanism.

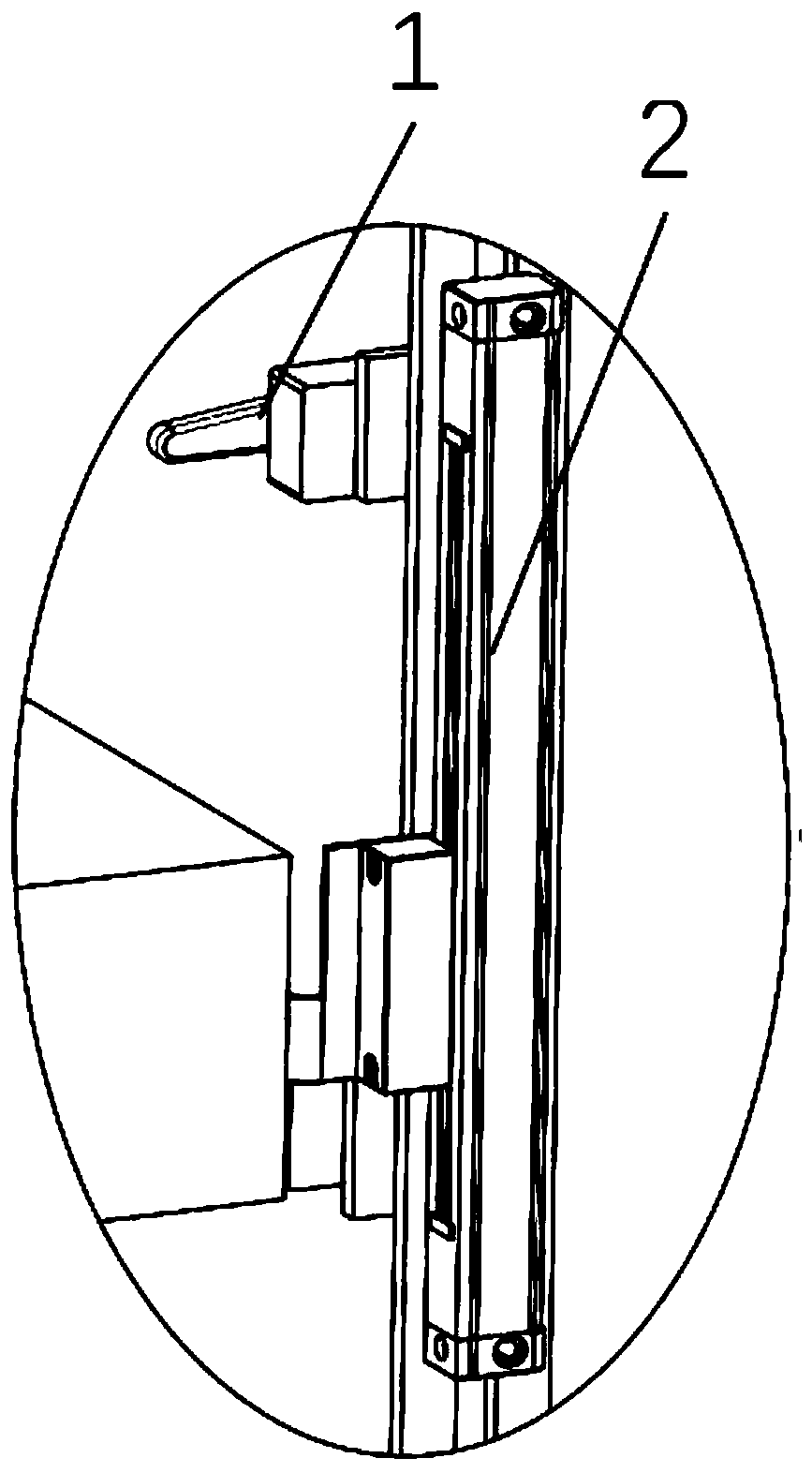

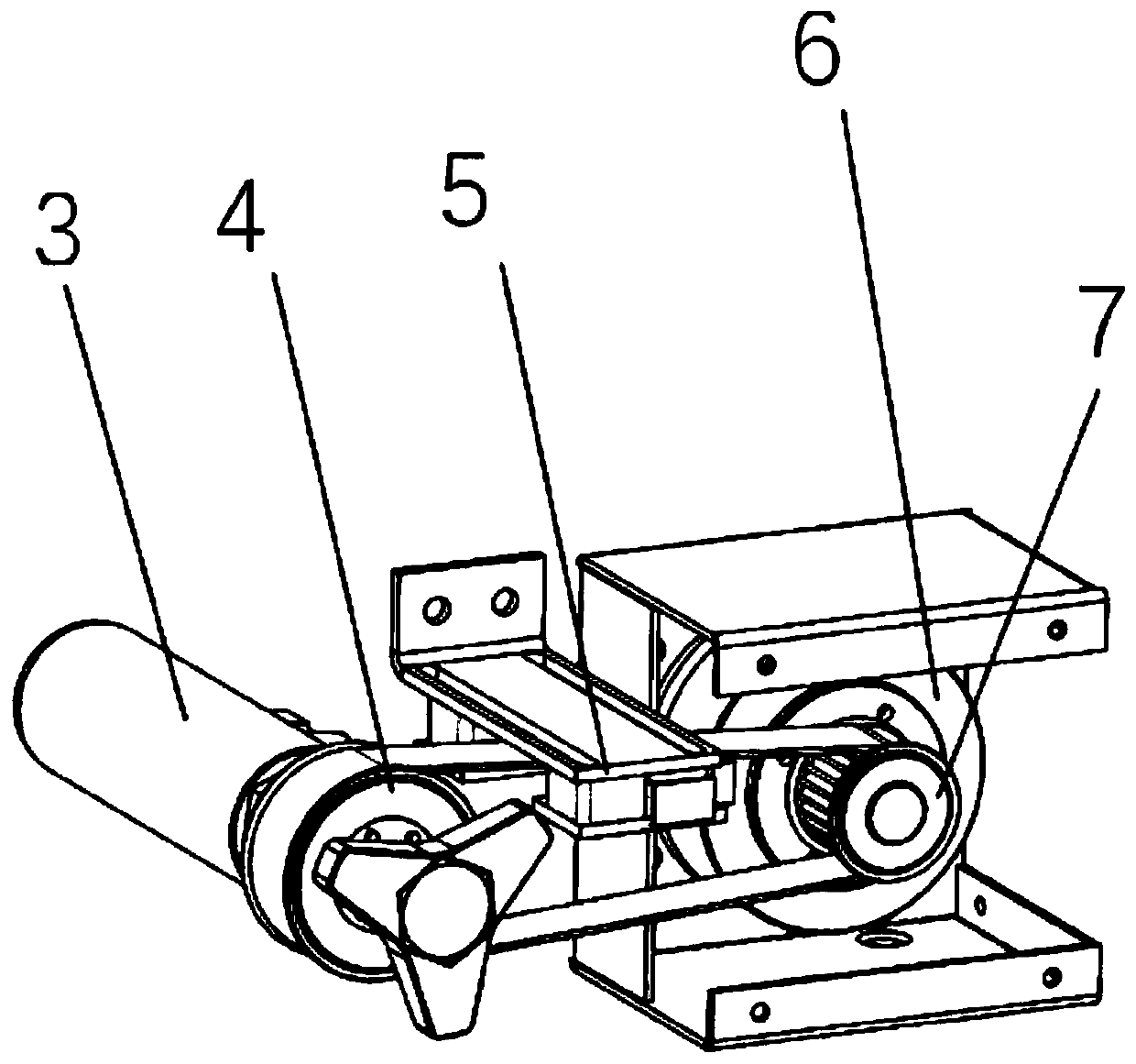

[0030] see figure 2 and image 3 shown, where figure 2 for figure 1 The enlarged structure of A (speed limit part) in middle, image 3 It is the enlarged structure diagram of B ...

Embodiment 2

[0037] Example 2: A control method for an automatic speed regulation and pressure control device for an extruder

[0038] refer to Figure 4 As shown, a control method using the automatic speed regulation and pressure control device of the extruder in Embodiment 1 specifically includes the following steps:

[0039] S1. The extruder starts to move, and the speed measuring and limit mechanism of the extruder accurately measures the dynamic speed of the extruder, and then converts it into a pulse signal output and feeds it back to the microcomputer controller in the control system;

[0040] S2. The microcomputer controller in the control system adjusts the target motion speed parameters of the extruder by setting the parameters of each extrusion stage of the product according to the user, and then converts the target motion parameters into analog signals, and finally controls them in real time through the analog signals The movement speed and direction of the brushless motor;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com