A chain gasket quantitative supply and assembly equipment

A quantitative supply and assembly equipment technology, applied in the field of parts assembly, can solve the problems of affecting the NVH effect of the engine, the stability of the gasket is not long enough, the quantitative picking error of the gasket, etc., and achieves simple structure, long-lasting stability and reduced friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

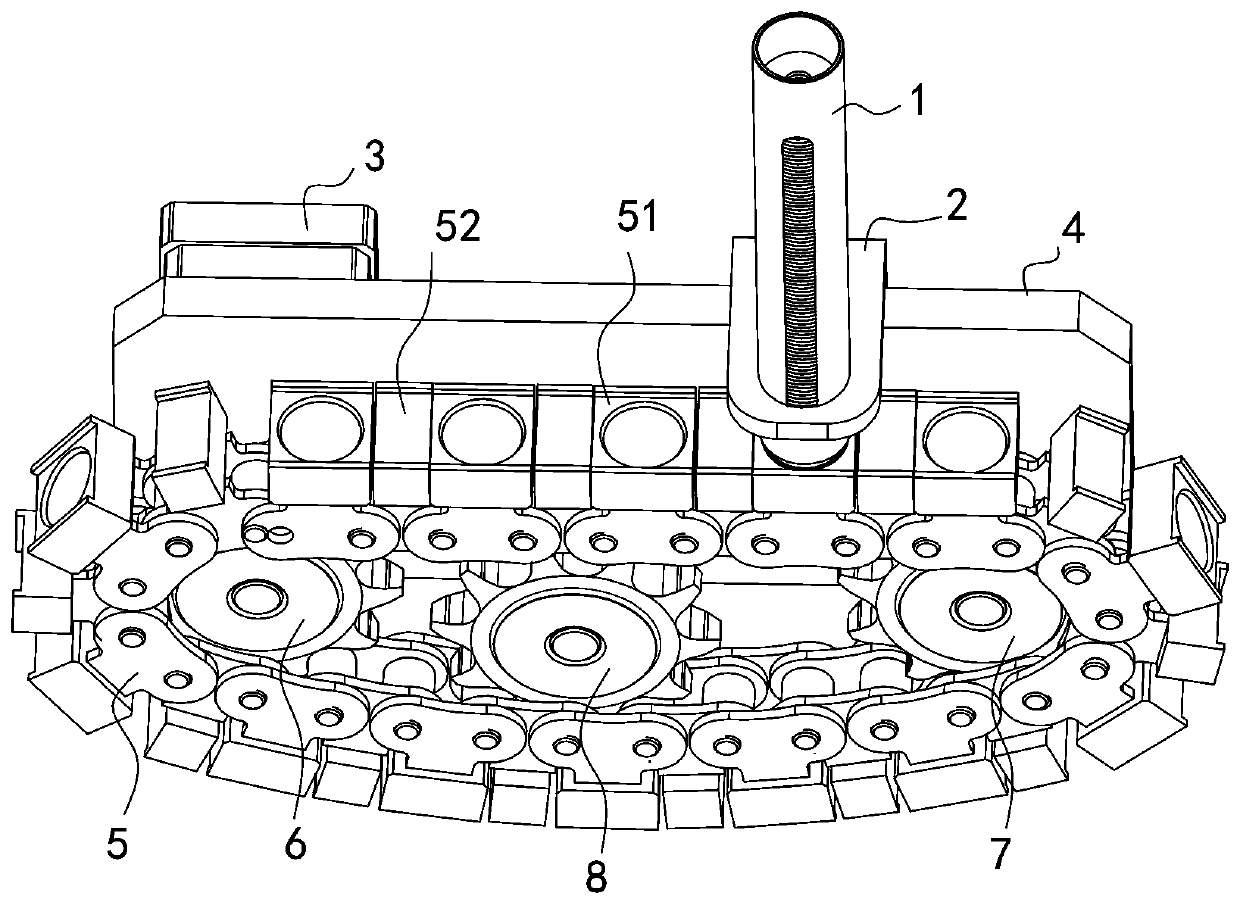

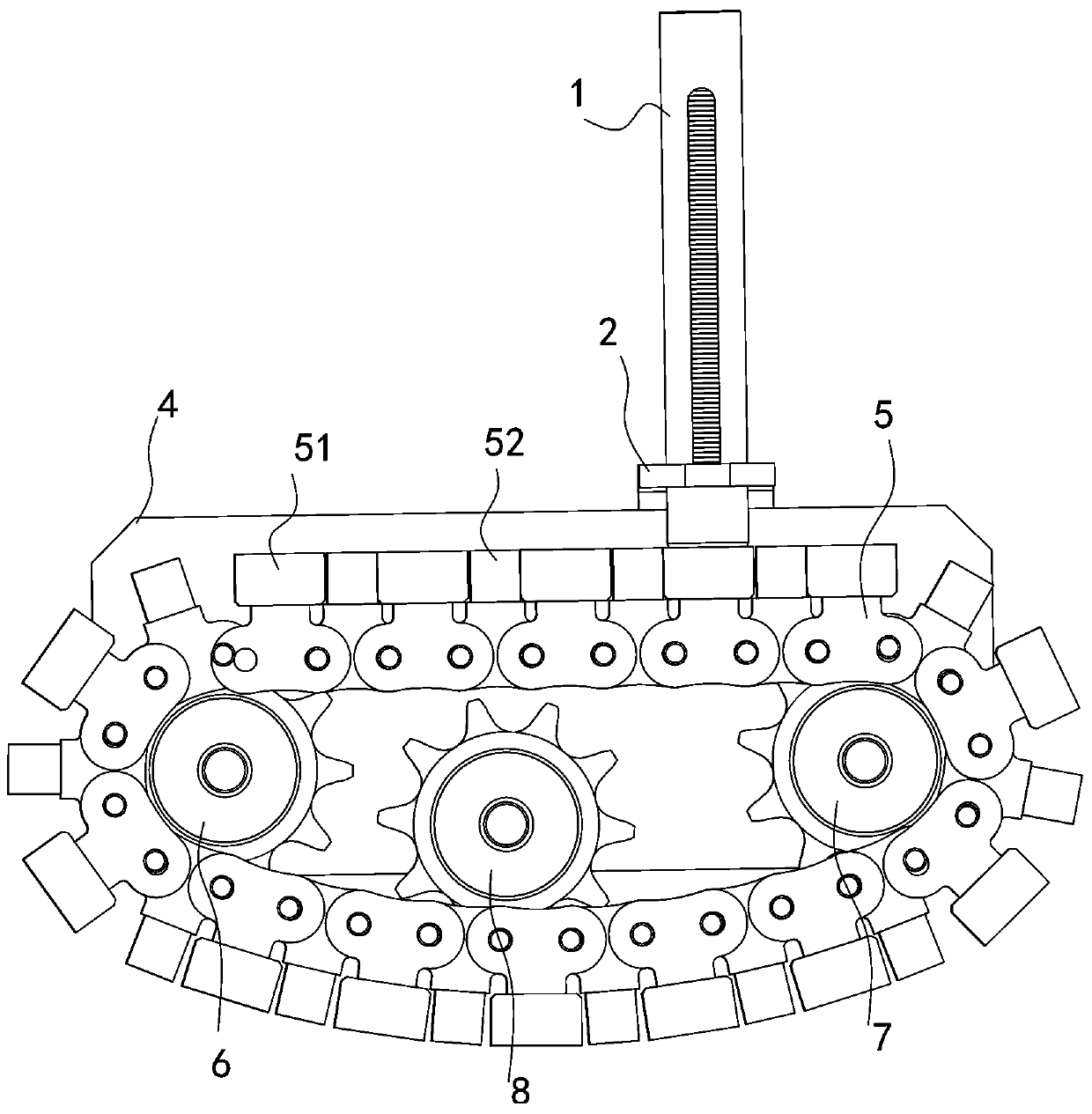

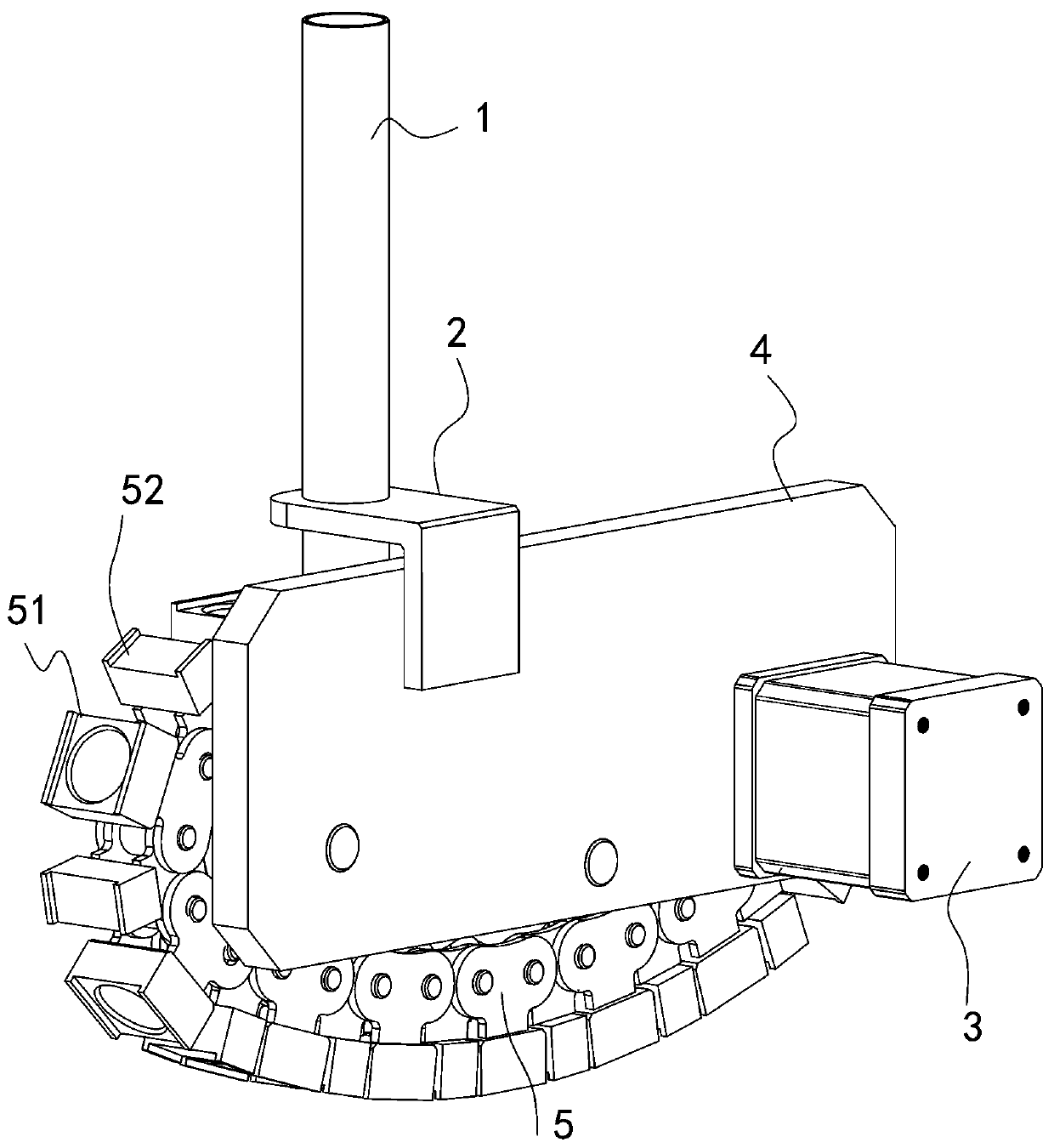

[0014] Such as Figure 1 to Figure 4 As shown, a chain gasket quantitative supply and assembly equipment described in this embodiment includes a barrel 1 for stacking gaskets, an L-shaped bracket 2, a servo motor 3, a fixing plate 4 and a chain 5, One end of the barrel 1 is fixed on one end of the bracket 2 and extends downward through the bracket 2, the other end of the bracket 2 is fixed on the fixing plate 4, and the servo motor 3 is fixed on the fixing plate 4, so The output end of the servo motor 3 passes through the fixed plate 4 and is connected with the driving sprocket 6 through the coupling, and the fixed plate 4 is connected with the first driven sprocket 7 and the second driven sprocket through the driven wheel shaft 8. The second driven sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com