Microfoam TPE artificial leather and production method thereof

A production method and technology of artificial leather, applied in the direction of chemical instruments and methods, lamination, application, etc., can solve the problems of foaming ratio less than 1, micro-foaming, difficult continuous foaming, etc., to improve efficiency and reduce Operation error, good feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

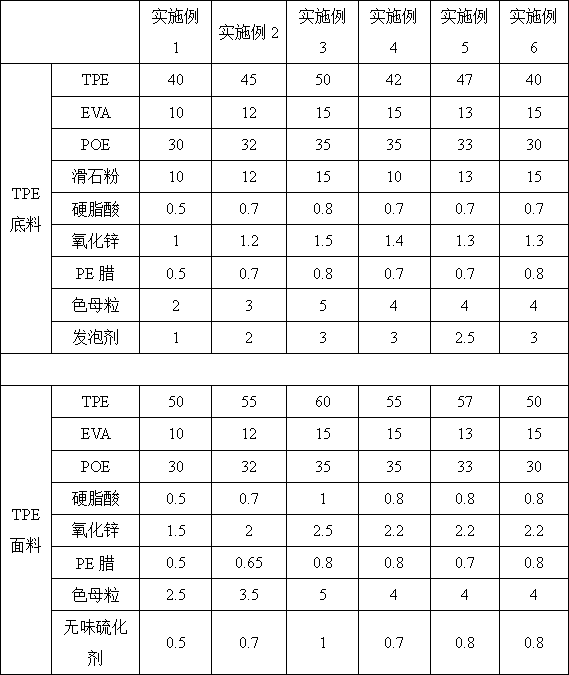

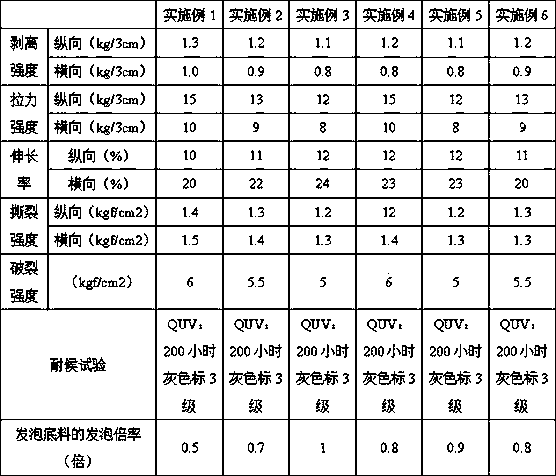

[0085] Embodiment 1-6 Micro-foaming TPE artificial leather

[0086] Weigh the raw materials according to the proportions in Table 1 respectively, and prepare according to the following steps, the difference is that the added raw material proportions are different, and the products are prepared, see Table 1 for details:

[0087] Table 1: Raw material ratio table of embodiment 1-6

[0088]

[0089] The preparation method of this slightly foamed TPE artificial leather comprises the steps:

[0090] The steps of making TPE base material with cloth: mix TPE, EVA, POE, talcum powder, stearic acid, zinc oxide, PE wax, color masterbatch, and foaming agent in the prescribed amount, and then knead and calender to obtain TPE base material sheet; the TPE base material sheet is bonded to the base cloth, and after the lamination, it is shaped by the cooling wheel group, and the temperature is controlled at 12-16°C, and it is wound to obtain the TPE base material with cloth; the base Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com