Protective device for rotating buckle machine in emulsion explosive production line

A technology of emulsion explosives and protective devices, which is applied in the directions of packaging, transportation packaging, and conveyor objects, etc., can solve the problems affecting the timeliness of the operation of the rotary buckle machine, the cumbersome operation of the protective structure, and the shutdown of the rotary buckle machine. Eliminate accidental fall accidents of the fence, improve convenience and efficiency, and facilitate installation and removal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

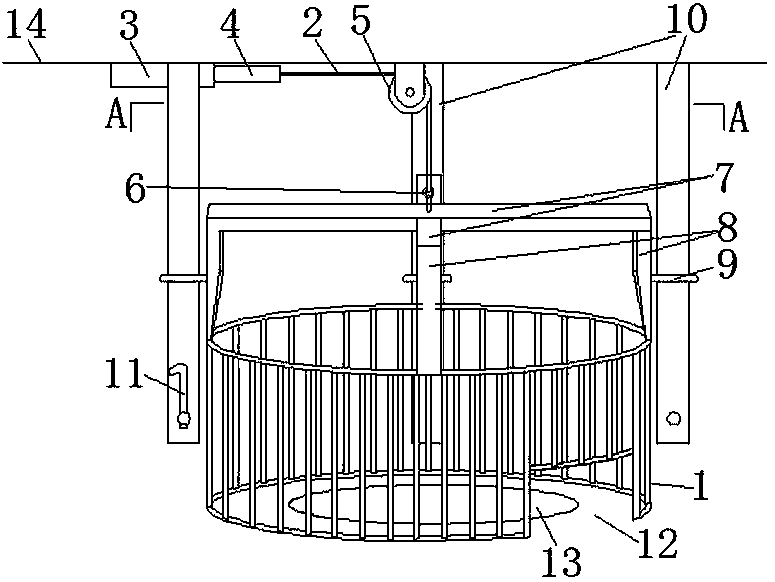

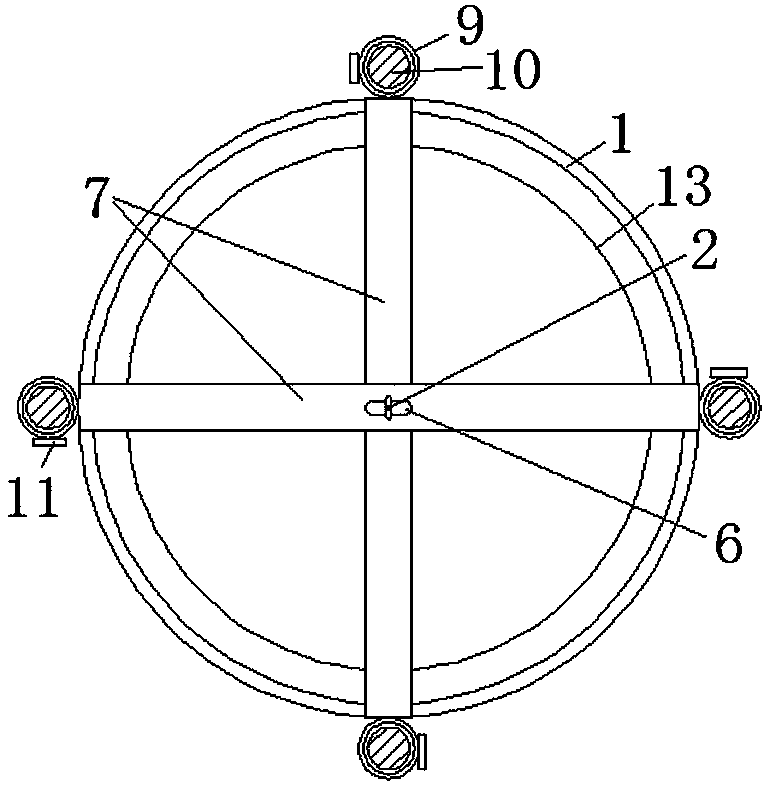

[0022] see figure 1 and figure 2 As shown, the present invention is a protective device for a rotary buckle machine in an emulsion explosive production line, which includes a fence 1, a sling 2, a power source and a guide column 10.

[0023] Wherein, the circumferential direction of the fence 1 is a fence structure, and the circumferential contour of the fence 1 is required to correspond to the outer contour of the rotary buckle machine 13, and to be slightly larger than the outer contour of the rotary buckle machine 13, based on the rotary buckle The machine 13 is a disc-shaped structure, and therefore, the fence 1 is a ring structure slightly larger than the rotary buckle machine 13. In addition, the height of the fence 1 should usually ensure that the fence 1 is located behind the base of the outer circumference of the rotary snap-fit machine 13, and is equal to or slightly higher than the working part of the rotary snap-fit machine 13, or slightly higher than the ope...

Embodiment 2

[0031] The invention is a protection device for a rotary buckle machine in an emulsion explosive production line, which includes a fence, a hanging rope, a power source and a guide column.

[0032] Among them, the perimeter of the fence is a fence structure, which requires that the perimeter profile of the fence should not only correspond to the outer profile of the rotary snap-in machine, but also be slightly larger than the outer profile of the rotary snap-in machine, based on the fact that the rotary snap-in machine is disc-shaped The structure, therefore, the fence is a ring structure slightly larger than the rotary buckle machine. In addition, the height of the fence should usually ensure that the fence is located behind the base of the outer periphery of the rotary clipping machine, and is equal to or slightly higher than the working part of the rotary clipping machine, that is, the height of the fence The height should depend on the height of the seating base on the per...

Embodiment 3

[0040] The invention is a protection device for a rotary buckle machine in an emulsion explosive production line, which includes a fence, a hanging rope, a power source and a guide column.

[0041] Among them, the perimeter of the fence is a fence structure, which requires that the perimeter profile of the fence should not only correspond to the outer profile of the rotary snap-in machine, but also be slightly larger than the outer profile of the rotary snap-in machine, based on the fact that the rotary snap-in machine is disc-shaped The structure, therefore, the fence is a ring structure slightly larger than the rotary buckle machine. In addition, the height of the fence should usually ensure that the fence is located behind the base of the outer periphery of the rotary clipping machine, and is equal to or slightly higher than the working part of the rotary clipping machine, that is, the height of the fence The height should depend on the height of the seating base on the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com