Pre-treatment method for improving anaerobic treatment efficiency of etimicin sulfate synthetic wastewater

An etimicin sulfate and anaerobic treatment technology, applied in anaerobic digestion treatment, special compound water treatment, multi-stage water treatment, etc., can solve the problems of high COD in effluent, poor THF bioavailability, and poor COD removal effect , to achieve the effect of improving biochemical performance, improving COD removal efficiency and reducing pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Inoculate anaerobic sludge in the pretreatment tank, and add etimicin sulfate wastewater (COD>10000mg / L) into the pretreatment tank. The inoculation volume of anaerobic sludge is 1 / 3 of the effective volume of the pretreatment tank. The remaining volume of the treatment tank is filled up with etimicin sulfate wastewater. Then add K to etimicin sulfate wastewater 2 HPO 4 , the K added to the pretreatment pool 2 HPO 4 The concentration is 8 mg / L, and the wastewater and anaerobic sludge in the pretreatment tank are stirred intermittently with a mixer, and the stirring speed of the mixer is 180 rpm.

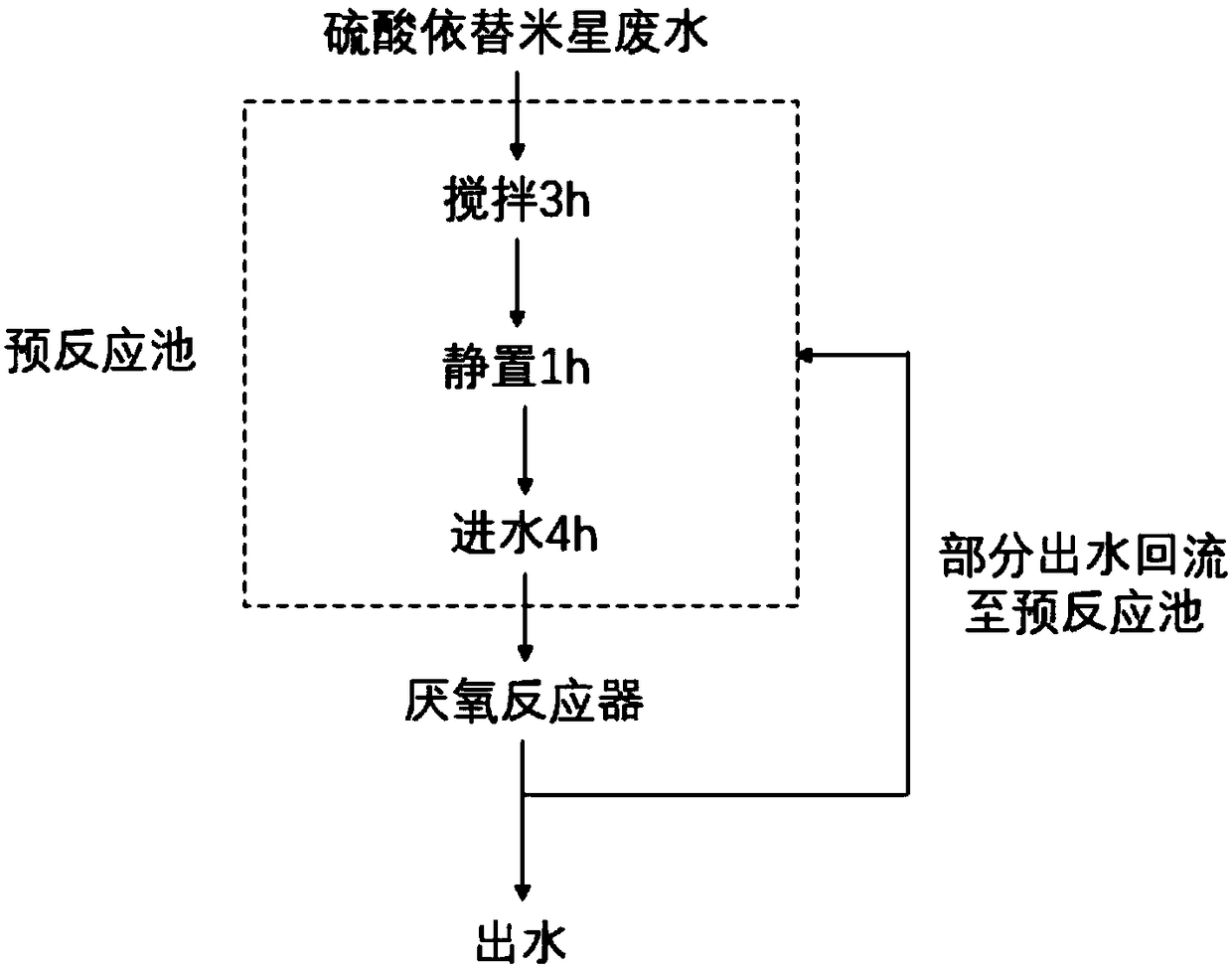

[0044] In the preprocessing process, every 8h is a cycle, and each cycle can be divided into 3 stages:

[0045](I) The treatment time of the first stage is 3 hours. In this stage, a mixer is used to continuously stir, and folic acid is continuously and uniformly added to the etimicin sulfate wastewater. The total concentration of folic acid added is 30mg / L. The middle pH ...

Embodiment 2

[0050] Inoculate anaerobic sludge in the pretreatment tank, and add etimicin sulfate wastewater (COD>10000mg / L) into the pretreatment tank. The inoculation volume of anaerobic sludge is 1 / 4 of the effective volume of the pretreatment tank. The remaining volume of the treatment tank is filled up with etimicin sulfate wastewater. Then add K to etimicin sulfate wastewater 2 HPO 4 , the K added to the pretreatment pool 2 HPO 4 The concentration is 9 mg / L, and the wastewater and anaerobic sludge in the pretreatment tank are stirred intermittently with a mixer, and the stirring speed of the mixer is 180 rpm.

[0051] In the preprocessing process, every 8h is a cycle, and each cycle can be divided into 3 stages:

[0052] (I) The treatment time of the first stage is 3 hours. In this stage, a mixer is used to continuously stir, and folic acid is continuously and uniformly added to the etimicin sulfate wastewater. The total concentration of folic acid added is 45mg / L. The middle pH...

Embodiment 3

[0057] Inoculate anaerobic sludge in the pretreatment tank, and add etimicin sulfate wastewater (COD>10000mg / L) into the pretreatment tank. The inoculation volume of anaerobic sludge is 1 / 6 of the effective volume of the pretreatment tank. The remaining volume of the treatment tank is filled up with etimicin sulfate wastewater. Then add K to etimicin sulfate wastewater 2 HPO 4 , the K added to the pretreatment pool 2 HPO 4 The concentration is 13mg / L, and the wastewater and anaerobic sludge in the pretreatment tank are intermittently stirred by a mixer, and the stirring speed of the mixer is 180rpm.

[0058] In the preprocessing process, every 8h is a cycle, and each cycle can be divided into 3 stages:

[0059] (I) The treatment time of the first stage is 3 hours. In this stage, a mixer is used to continuously stir, and folic acid is continuously and uniformly added to the etimicin sulfate wastewater. The total concentration of folic acid added is 50mg / L. The middle pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com