Application of reverse osmosis concentrated water generated in paper-making industry in snow-melting agents

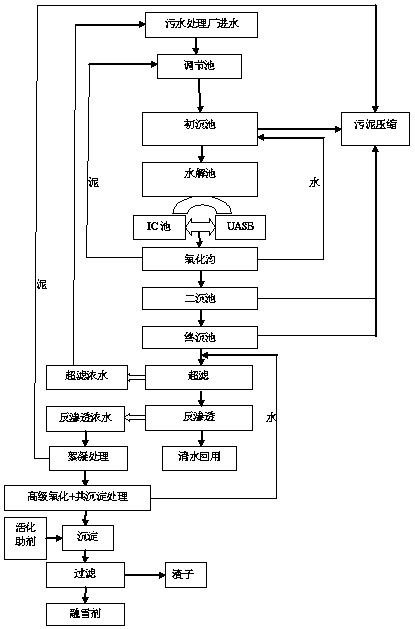

A technology of reverse osmosis concentrated water and deicing agent, which is applied in water/sewage treatment, process wastewater treatment, oxidized water/sewage treatment, etc. It can solve the problems of deicing agent performance impact, poor snowmelting effect, environmental pollution, etc., to achieve The effect of solving environmental problems, simple technological process, and good industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Adopt the process of the present invention to treat papermaking reverse osmosis concentrated water with high CODcr content (1355 mg / L), 0.9485

[0043] Step 1: Take 700mL paper-making reverse osmosis concentrated water and put it into a 1000mL three-necked bottle, add 3.79g flocculant (4 times the CODcr), T=30±2°C, keep warm for 30 minutes, stir at 350 rpm, and then add coagulation aid Agent (0.05 times of CODcr) 47mg, stirring speed is 20-100 rpm, T=30±2°C, holding time is 30 minutes, stirring speed is 80 rpm, filter the concentrated reverse osmosis water after flocculation with medium-speed quantitative filter paper, Dilute the filtrate to 700 mL with distilled water for later use.

[0044] Step 2: Add 700mL of the filtrate in step 1 into a 1000mL three-necked flask, add 4.74g of advanced oxidant (5 times that of CODcr), pH=3.0±1.0, T=30±2°C, keep warm for 60 minutes, and stir at 350 rpm , add coprecipitant (5 times of CODcr) 4.74g immediately after advanced oxidatio...

Embodiment 2

[0047] Adopt the process of the present invention to treat papermaking reverse osmosis concentrated water with low CODcr content (920 mg / L),

[0048] Step 1: Take 700mL paper-making reverse osmosis concentrated water and put it into a 1000mL three-necked bottle, add 2.58g flocculant (4 times of CODcr), T=30±2°C, keep warm for 30 minutes, stir at 350 rpm, and then add coagulation aid Agent (0.05 times of CODcr) 32mg, the stirring speed is 20-100 rpm, T=30±2°C, the holding time is 30 minutes, the stirring speed is 80 rpm, and the concentrated reverse osmosis water after flocculation is filtered with medium-speed quantitative filter paper, Dilute the filtrate to 700 mL with distilled water for later use.

[0049] Step 2: Add 700mL of the filtrate in step 1 into a 1000mL three-necked flask, add 3.22g of advanced oxidant (5 times that of CODcr), pH=3.0±1.0, T=30±2°C, keep warm for 60 minutes, and stir at 350 rpm , add coprecipitant (5 times of CODcr) 3.22g immediately after advanc...

Embodiment 3

[0052] Compared with Example 1, 0.5 g of activator was added, T=40±2°C, the holding time was 60 minutes, the stirring speed was 350 rpm, and the rest were the same as in Example 1. The prepared snow-melting agent has a measured relative snow-melting and ice-melting ability of 105%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com