Drying and pulverizing apparatus for treating mercury-containing sludge

A technology for drying and pulverizing sludge, which is used in grain treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problem of high labor costs for sludge pulverization and complex structure of drying and pulverizing devices. , low crushing efficiency and other problems, to achieve the effect of easy promotion and use, simple and clear design structure, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

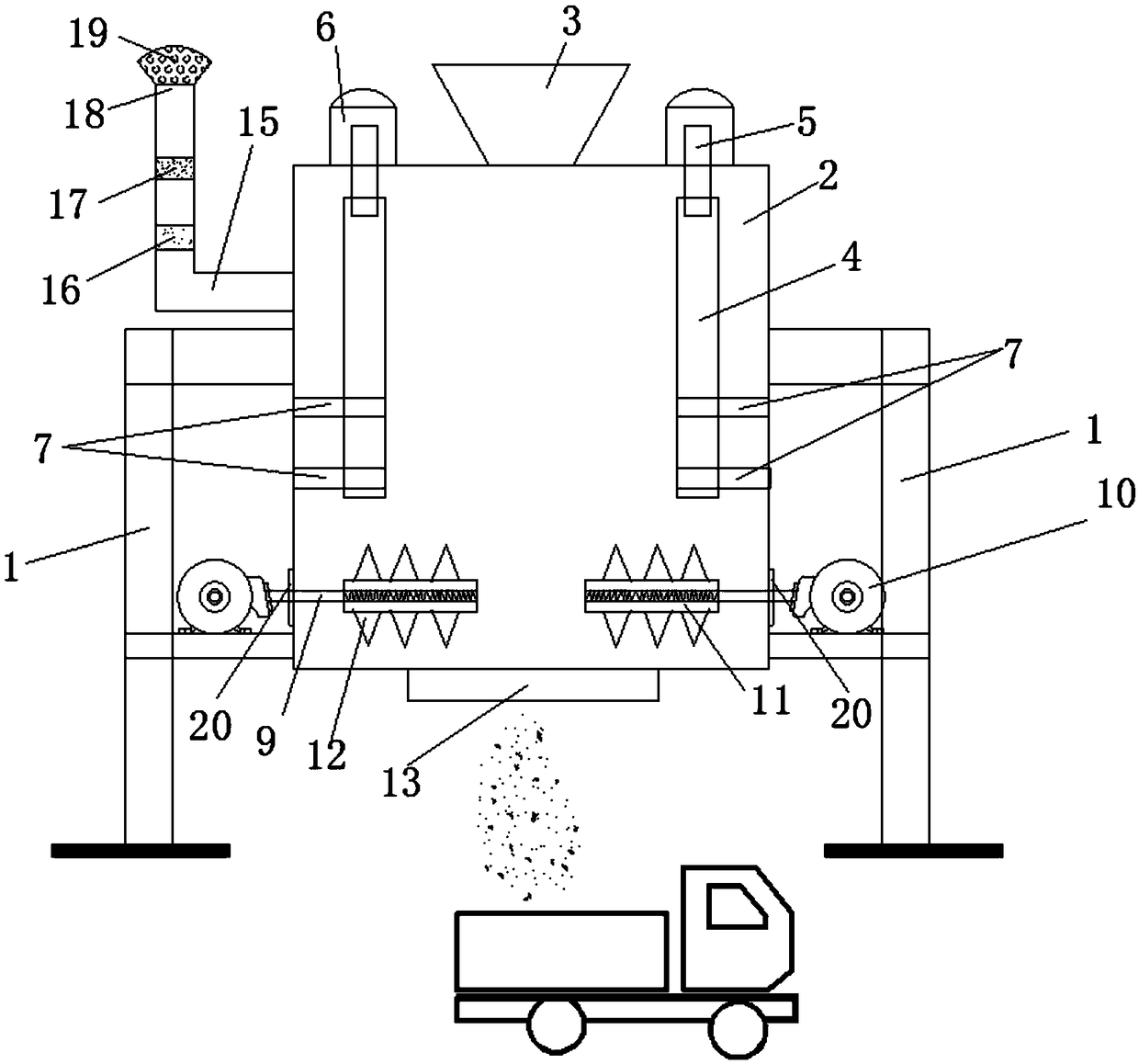

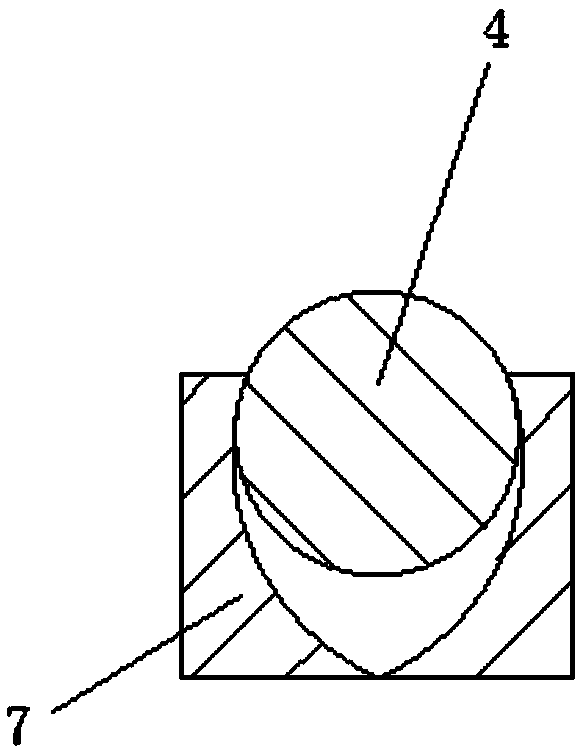

[0017] Embodiment 1: see figure 1 and figure 2 Now, a drying and pulverizing device for treating mercury-containing sludge provided by the present invention will be described, including a body 2 fixed on a frame 1, and a feeding hopper 3 is provided on the upper part of the body 2, and the feeding The two ends of bucket 3 are provided with electric heating tube 4 respectively, and described electric heating tube 4 is connected with motor 6 through power supply body 5, and described electric heating tube 4 is cylindrical, and its bottom end is fixedly installed on the fixed frame 7, so The fixed frame 7 is a disc-shaped double-layered fixed frame, and the lower end of the body 2 is provided with a stirring assembly 8, and the stirring assembly 8 includes a stirring shaft 9, and one end of the stirring shaft 9 is connected to the stirring motor 10 outside the body 2. One end is threadedly connected to the crushing shaft 11, the shaft body of the crushing shaft 11 is provided w...

Embodiment 2

[0018] Example 2: see figure 1 , as an improvement of the present invention, the outer end of the stirring shaft 9 and the body 2 is provided with an annular sealing ring 20 .

Embodiment 3

[0019] Embodiment 3: see figure 1 , As an improvement of the present invention, the dust filter 19 adopts a HEPA filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com