Preparation method of clean-water fracture propping agent

A clean water fracturing and proppant technology, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of high density and poor suspension of fracturing proppants, and reduce fracturing costs, Good stability and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

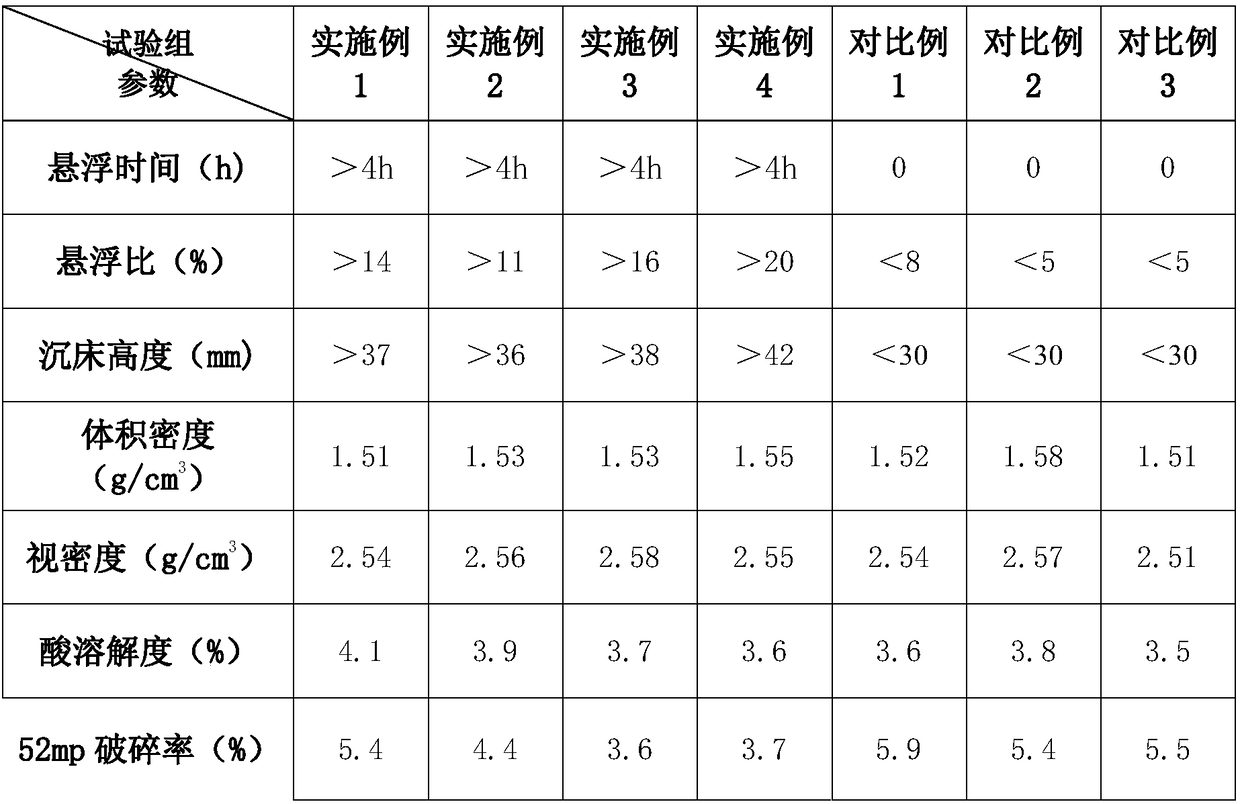

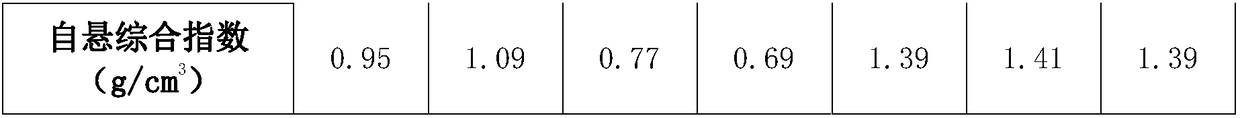

Embodiment 1

[0041] A method for preparing a clear water fracturing proppant, comprising the following steps:

[0042] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 2 parts of resin, 1.1 part of curing agent, and 0.01 part of catalyst. The aggregate is 20 / 40 quartz sand, the resin is glycerol polymer, the curing agent is toluene diisocyanate, and the catalyst is dibutyltin dilaurate.

[0043] (2) Heat the aggregate to 90°C, add resin and catalyst, and mix and stir;

[0044] (3) When the temperature drops to 80°C, add a curing agent and mix and stir; when the temperature drops to 50°C, take it out of the pot to obtain a clear water fracturing proppant.

[0045] The energy spectrum test characteristic of the proppant coating layer prepared in this example is that the atomic ratio of carbon to oxygen is 5:1.

Embodiment 2

[0047] A method for preparing a clear water fracturing proppant, comprising the following steps:

[0048] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 2.5 parts of resin, 1.63 parts of curing agent, and 0.015 parts of catalyst. The aggregate is 30 / 50 quartz sand, the resin is propylene glycol polymer, the curing agent isophorone diisocyanate, and the catalyst is tributyltin.

[0049] (2) Heat the aggregate to 100°C, add resin and catalyst, and mix and stir;

[0050] (3) When the temperature drops to 90°C, add a curing agent and mix and stir; when the temperature drops to 60°C, take it out of the pot to obtain a clean water fracturing proppant.

[0051] The energy spectrum test characteristic of the proppant coating layer prepared in this example is that the atomic ratio of carbon to oxygen is 6:1.

Embodiment 3

[0053] A method for preparing a clear water fracturing proppant, comprising the following steps:

[0054] (1) Prepare the following raw materials in parts by mass: 100 parts of aggregate, 3 parts of resin, 2.3 parts of curing agent, and 0.02 parts of catalyst. Among them, 40 / 70 quartz sand is used as the aggregate, propanol polymer is used as the resin, diphenylmethane diisocyanate is used as the curing agent, and lead isooctoate is used as the catalyst.

[0055] (2) Heat the aggregate to 110°C, add resin and catalyst, and mix and stir;

[0056] (3) When the temperature drops to 100°C, add a curing agent and mix and stir; when the temperature drops to 70°C, take it out of the pot to obtain a clear water fracturing proppant.

[0057] The energy spectrum test characteristic of the proppant coating layer prepared in this example is that the atomic ratio of carbon to oxygen is 7:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com