Stainless steel for oil well pipes with microbiological corrosion resistance and preparation method thereof

A technology of anti-microbial and manufacturing methods, which is applied in the field of stainless steel for oil well pipes with anti-microbial corrosion performance and its manufacturing field, which can solve the problems of not considering the anti-microbial corrosion performance of materials, damage to oil layers, blockage of pipelines, etc., and achieve excellent stress resistance Effects of corrosion cracking performance, excellent resistance to microbial corrosion, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

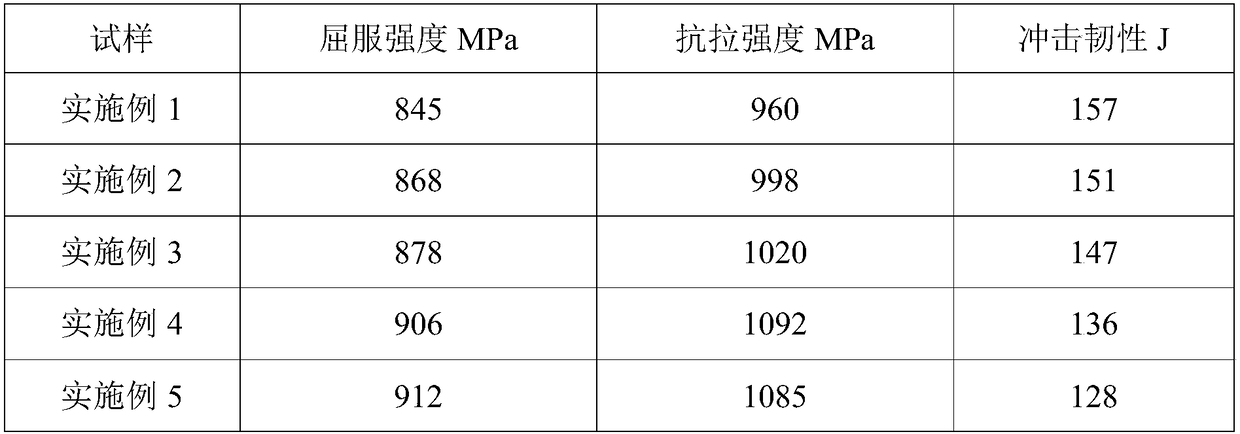

Examples

Embodiment Construction

[0032] The present invention will be described below by comparing different examples and comparative examples. These examples are only for explanatory purposes, and the present invention is not limited to these examples.

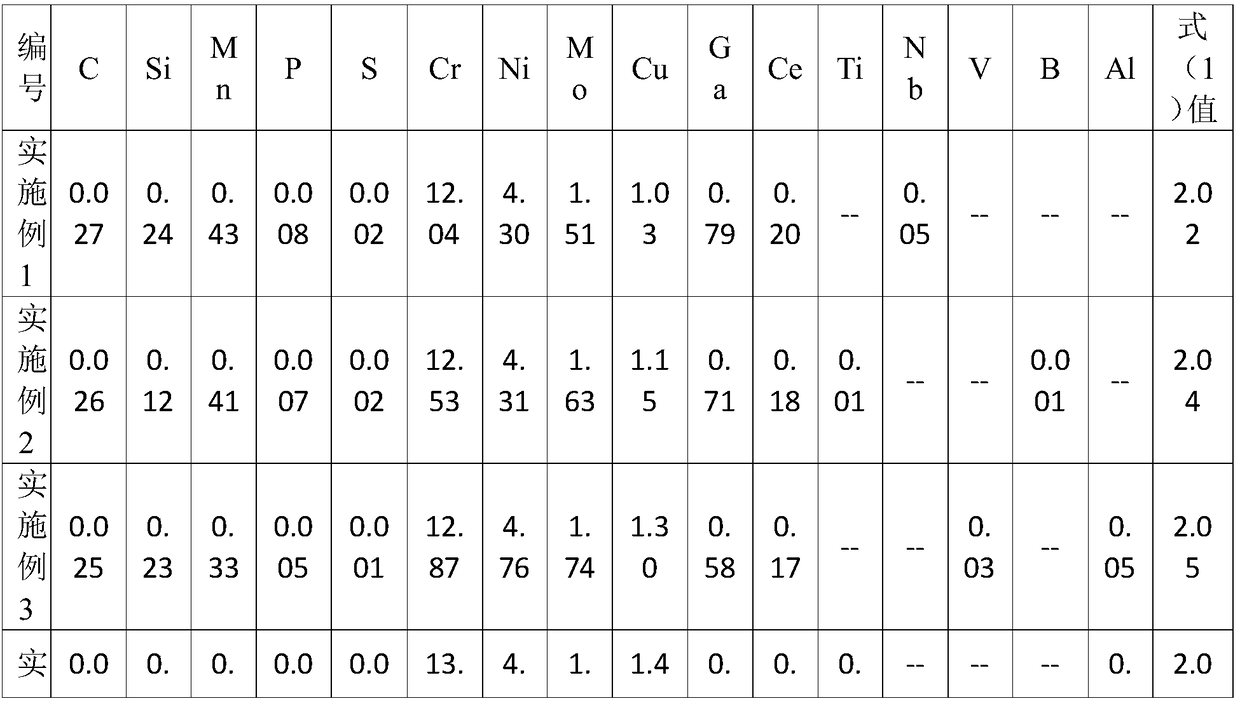

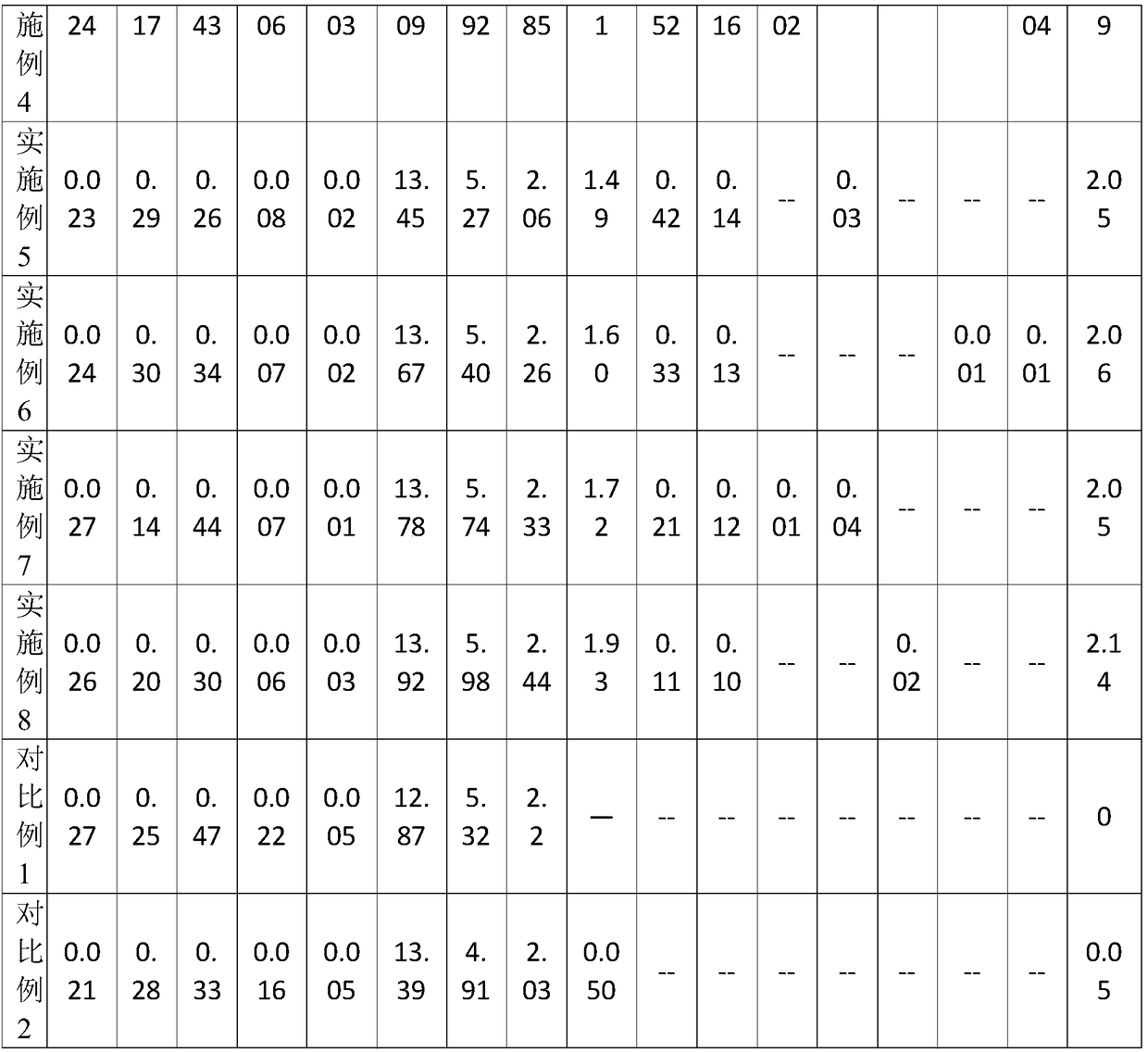

[0033] Table 1 shows the chemical composition of various steels in the Examples and Comparative Examples.

[0034] The specific preparation steps are:

[0035] The examples and comparative examples are smelted in a 25kg vacuum induction furnace. The steel ingots are heated and forged in the austenite single-phase zone. The initial forging temperature ranges from 1100-1150°C, and the final forging temperature is not less than 900°C; the first time of the embodiment steel ingot Forging deformation is less than 10%, and the total forging ratio is more than 6.

[0036] The steels of various examples and comparative examples were forged and air-cooled to 550°C and put into a 550°C heat treatment furnace for heat preservation for 60 minutes.

[0037] Table 1 Example and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com