A method of backfilling the circumference of a road shaft

A technology for roads and road bases, used in excavation, waterway systems, buildings, etc., can solve problems such as subsidence of the road around inspection wells and storm drains, uncoordinated surrounding bases, affecting driving safety, etc., and reduce the possibility of cracking or settlement. performance, improve coordination and cohesion, increase stability and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

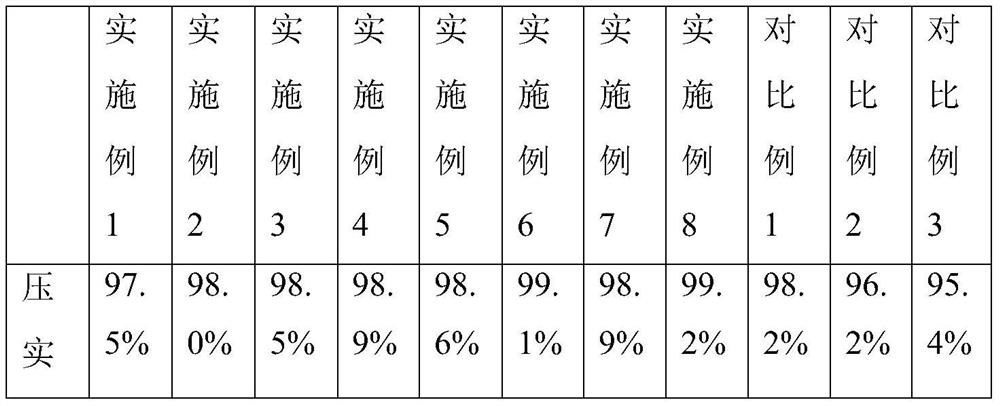

Embodiment 1

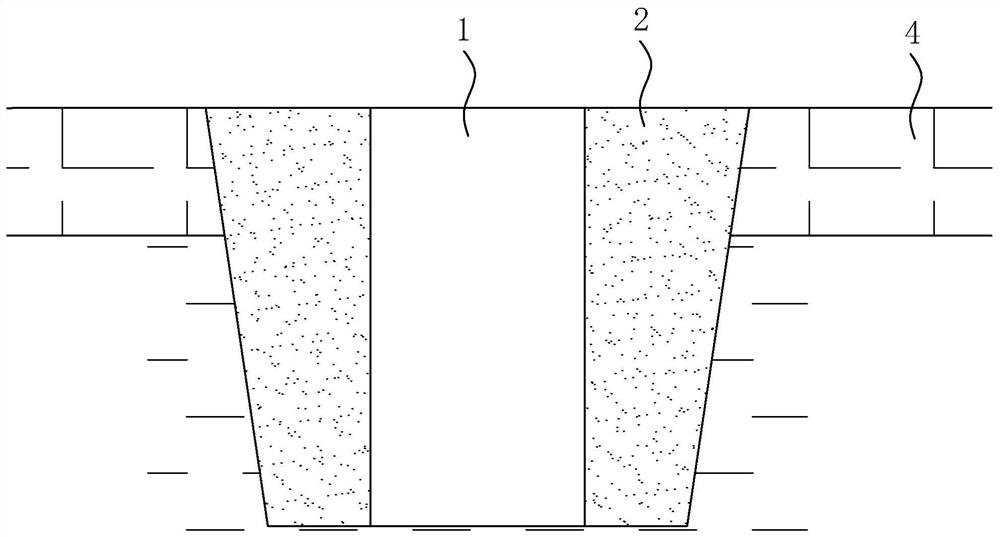

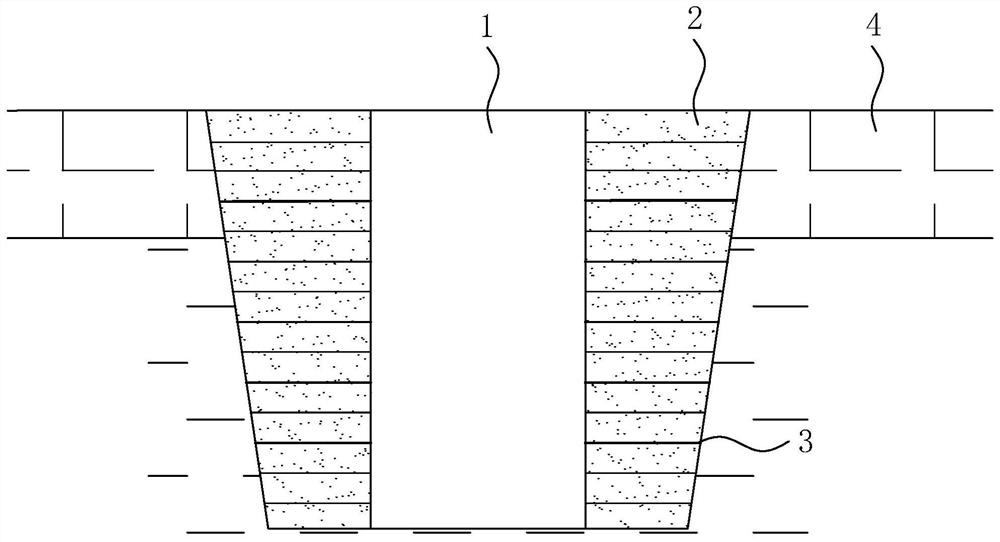

[0036] A method for backfilling around a road shaft shaft, comprising the following steps:

[0037] S1, prepare filler, mix the remaining inorganic material and cement after the road base construction process to form a mixture evenly, the amount of cement is 2wt% of the amount of inorganic material, wherein, the remaining inorganic material used is composed of the mass ratio of raw cement: crushed Stone: Soil = 1:20:30 It is made by stirring and mixing raw materials, and the gradation of crushed stone is:

[0038] 0mm

[0039] 3mm

[0040] 10mm

[0041] 20mm

[0042] 30mm

[0043] The original cement is ordinary portland cement of No. 325;

[0044] Mix 70wt% mixture with water evenly to form filler A, the water content of filler A is less than 2% of the optimum water content of inorganic material;

[0045] The remaining part of the mixture is unifor...

Embodiment 2

[0049] A method for backfilling around a road shaft shaft, comprising the following steps:

[0050] S1, prepare filler, mix the remaining inorganic material and cement after the road base construction process to form a mixture evenly, the amount of cement is 3wt% of the amount of inorganic material, wherein, the remaining inorganic material used is composed of the mass ratio of raw cement: crushed Stone: soil = 1:30:40 raw materials are stirred and mixed, and the gradation of crushed stone is:

[0051] 0mm

[0052] 3mm

[0053] 10mm

[0054] 20mm

[0055] 30mm

[0056] The original cement is ordinary portland cement of No. 325;

[0057] Mix 70wt% of the mixture with water evenly to form filler A. The water content of filler A is 2% greater than the optimum water content of the inorganic material; the remaining part of the mixture is evenly mixed with...

Embodiment 3

[0061] A method for backfilling around a road shaft shaft, comprising the following steps:

[0062] S1, prepare filler, mix the remaining inorganic material and cement after the road base construction process to form a mixture evenly, the amount of cement is 2.5wt% of the amount of inorganic material, wherein, the remaining inorganic material used is composed of raw cement by mass ratio: Crushed stone: soil = 1:25:35 is made by stirring and mixing raw materials, and the gradation of crushed stone is:

[0063] 0mm

[0064] 3mm

[0065] 10mm

[0066] 20mm

[0067] 30mm

[0068] The original cement is ordinary portland cement of No. 325;

[0069] Mix 70wt% mixture with water evenly to form filler A, the water content of filler A is the optimum water content of inorganic material;

[0070] The remaining part of the mixture is uniformly mixed with water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com