Unbonded prestressed assembly-type joint provided with energy dissipation device and construction method

An energy-consuming device and non-bonding technology, which is applied to structural elements, protective buildings/shelters, building components, etc., can solve the problems of large earthquake response, low energy consumption, and complex construction, and achieve small building space, High energy dissipation capacity and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

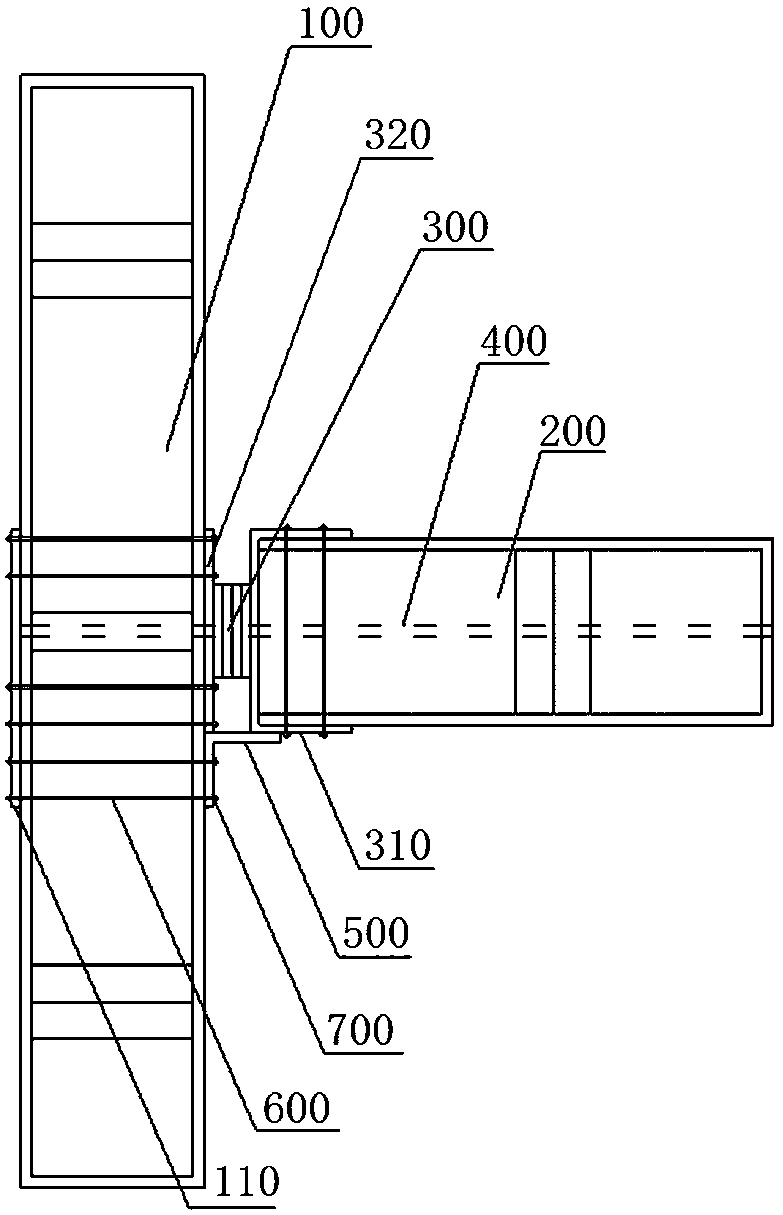

[0019] Embodiment 1: as figure 1 As shown, an unbonded prestressed prefabricated node with energy dissipation devices includes vertically connected precast concrete columns 100 and precast concrete beams 200, and the precast concrete columns 100 are vertically connected with precast concrete beams 200 on one side, That is, the connection node between the precast concrete column 100 and the precast concrete beam 200 is an edge node, the end of the precast concrete beam 200 and the side wall of the precast concrete column 100 are connected through a bellows damper 300, and one end of the bellows damper 300 is fixedly connected On the side wall of the precast concrete column 100, the other end of the bellows damper 300 is fixedly connected to the end of the precast concrete beam 200; the precast concrete beam and the precast concrete column are pierced with the same prestressed steel bar 400, and the prestressed steel bar 400 is connected by the bellows The damper passes through ...

Embodiment 2

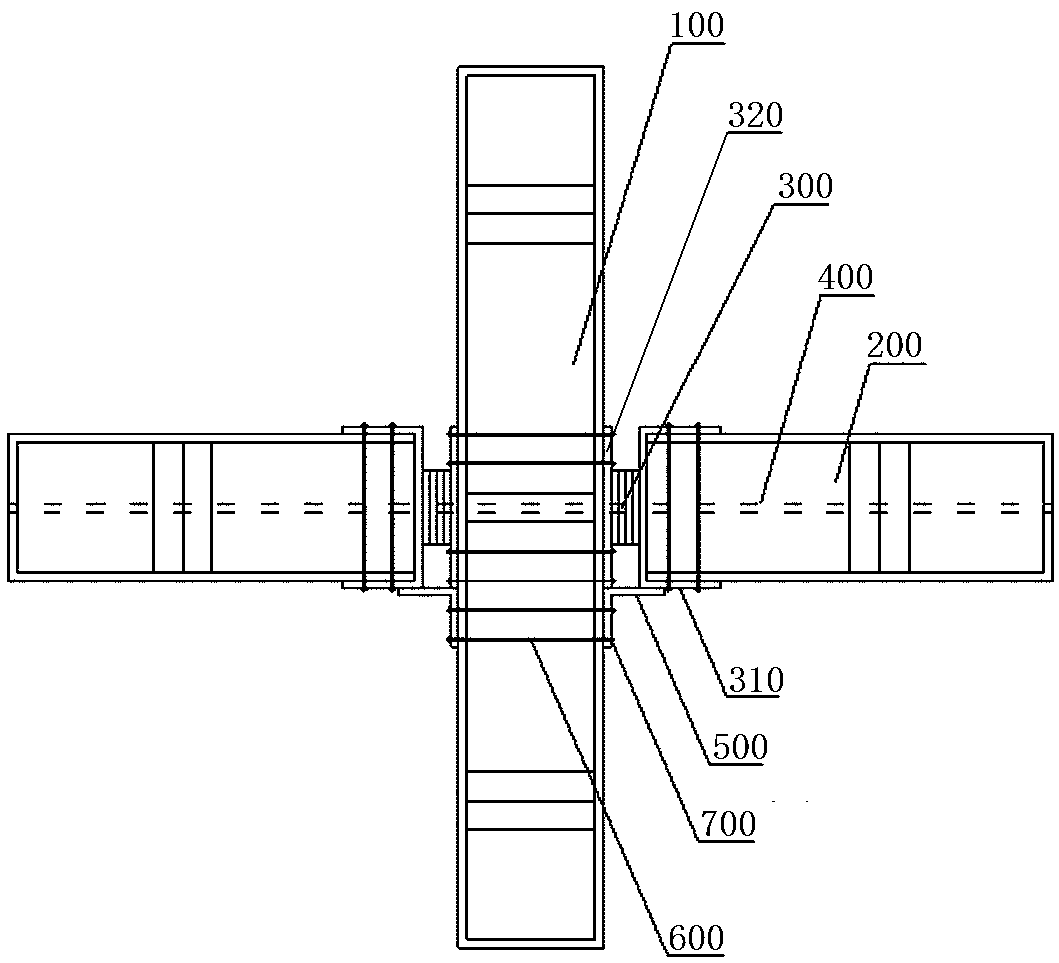

[0028] Embodiment 2: as figure 2 As shown, in this embodiment, the precast concrete column is vertically connected to the precast concrete beams on both sides, and the precast concrete column is located in the middle of the precast concrete beams on both sides, that is, the precast concrete column 100 and the two precast concrete beams 200 The connection node is the middle node, and the middle node does not need to use the connecting steel plate, but the angle steel 500 on both sides and the flat steel plate 320 on both sides are fixedly connected by the anchoring steel bar 600 pierced on the prefabricated concrete column, and the end of the anchoring steel bar After passing through the connecting angle steel or flat steel plate, it is locked by high-strength nut 700.

[0029] In this embodiment, the two ends of the prestressed steel bars are anchored to the far ends of the precast concrete beams on both sides; the precast concrete columns and the precast concrete beams are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com